Device and process for preparing scandium-containing aluminum alloy material

A technology for aluminum alloy materials and preparation devices, which is applied in the direction of cells, electrolytic processes, electrolytic components, etc., can solve the problems of high cost, high energy consumption, and high cost of scandium alloying, so as to inhibit recrystallization, increase strength, and enhance neutralization resistance. The effect of sub-irradiation damage properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

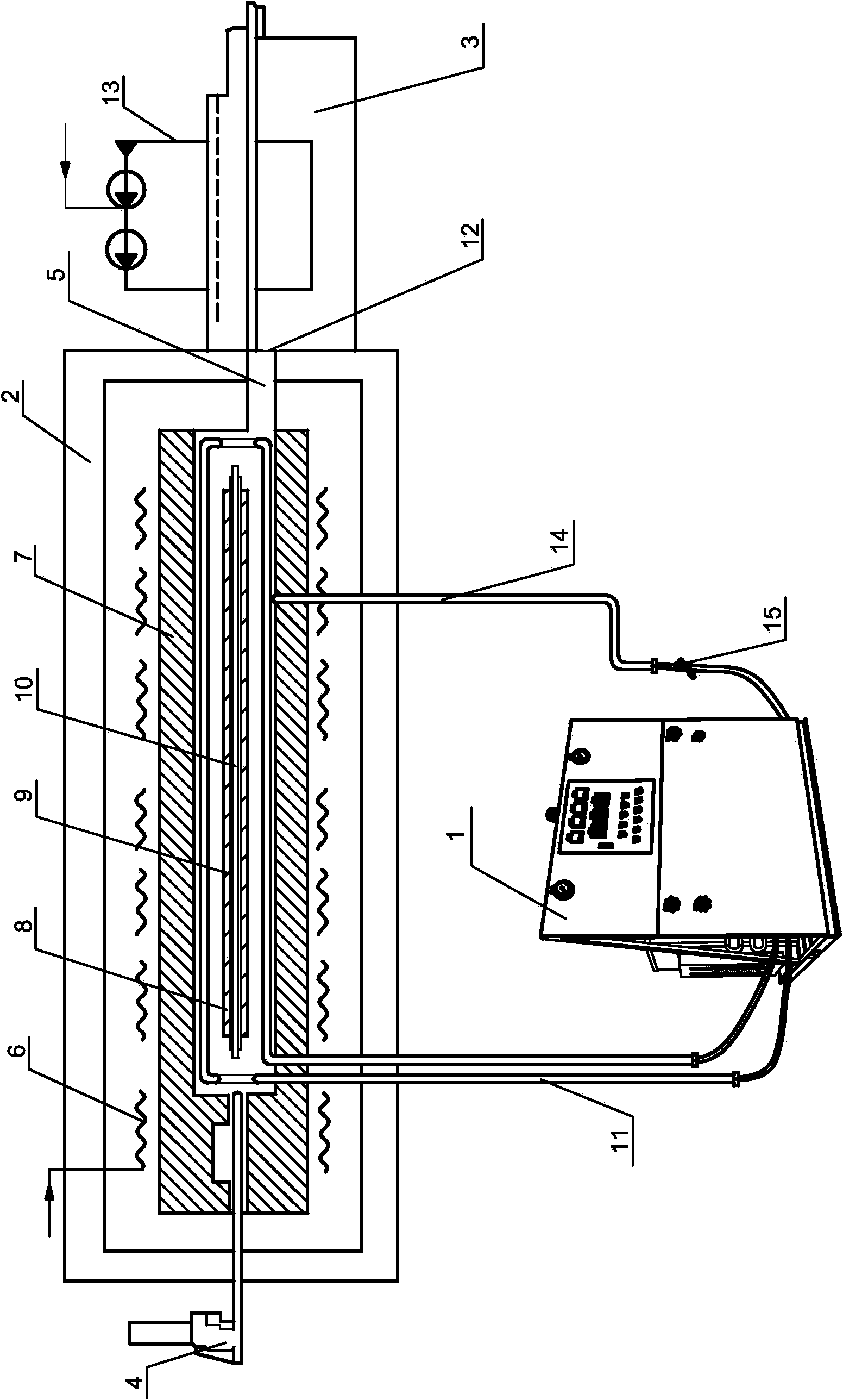

[0057] see figure 1 A preparation device for scandium-containing aluminum alloy materials, including a scandium-containing oxide decomposition control part 1, an electrolytic cell body 2 and a cooling part 3, an electrolyte input pipe 4, an alloy billet output pipe 5, an electric heating part 6, a graphite tank 7, and an anode Conductive pipe 8 , protective layer 9 , cathode conductive rod 10 , scandium-containing input pipe 11 , baffle plate 12 , cooling circulation system 13 , inert gas input pipe 14 and switch valve 15 .

[0058] One end of the electrolytic cell body 2 is provided with an electrolyte input pipe 4, and the other end is provided with an alloy billet output pipe 5. The electrolytic cell body 2 is sequentially provided with an electric heating part 6, a graphite tank 7, an anode conductive tube 8 and a cathode conductive rod 10; The conductive rod 10 is provided with a protective layer 9, the protective layer 9 is made of silicon nitride combined with silicon c...

Embodiment 1

[0064] The preparation process of scandium-containing aluminum alloy material comprises the following steps:

[0065] 1) Adding bauxite as raw material to the decomposition control part 1 of scandium-containing oxides, in the decomposition control part 1 of scandium-containing oxides, processing harmful impurities in minerals with high enrichment degree of scandium to obtain scandium-containing oxides, And detect the processed scandium-containing oxides to keep the mass ratio of scandium-containing oxides to harmful impurities at 30:1;

[0066] 2) Input the electrolyte raw material into the electrolytic cell body 2 through the electrolyte input pipe 4. The electrolyte raw material formula includes alumina, sodium fluoride and aluminum fluoride, and the electrolysis is carried out under the cryolite system. The mass fraction of the formula is: alumina 4.0% , sodium fluoride 40.0%, aluminum fluoride 28%, and the balance is unavoidable impurities; at the same time, the baffle pla...

Embodiment 2

[0073] The preparation process of scandium-containing aluminum alloy material comprises the following steps:

[0074] 1) Adding bauxite as raw material to the decomposition control part 1 of scandium-containing oxides, in the decomposition control part 1 of scandium-containing oxides, processing harmful impurities in minerals with high enrichment degree of scandium to obtain scandium-containing oxides, And the processed scandium-containing oxides are tested to keep the mass ratio of scandium-containing oxides to harmful impurities at 40:1;

[0075] 2) Input the electrolyte raw material into the electrolytic cell body 2 through the electrolyte input pipe 4. The electrolyte raw material formula includes alumina, sodium fluoride and aluminum fluoride, and the electrolysis is carried out under the cryolite system, and the mass fraction of the formula is: alumina 8.0% , sodium fluoride 50.0%, aluminum fluoride 32%, and the balance is unavoidable impurities; at the same time, the ba...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com