A high-density, acid-resistant and oxidation-resistant solid capacitor carbon foil production process

A solid-state capacitor and production process technology, applied in solid electrolytic capacitors, capacitors, electrolytic capacitors, etc., can solve the problems of poor precision coverage, affecting the acid and oxidation resistance of carbon foil, and prone to cracks.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

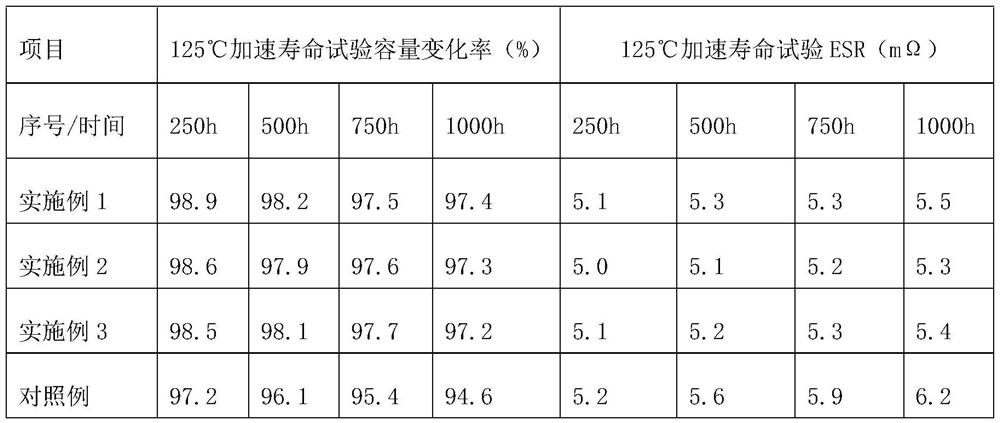

Embodiment 1

[0022] A high-density, acid-resistant and oxidation-resistant solid capacitor carbon foil production process, the process steps are as follows:

[0023] (1) Preparation of slurry:

[0024] ① Soak carbon nanotubes in a mixture of concentrated nitric acid and concentrated sulfuric acid for acidification: 1.5h, wash with deionized water until neutral, dry to obtain acidified carbon nanotubes, then mix with carbon nanotubes evenly, acidify carbon nanotubes and According to the mass ratio of carbon nanotubes to 2:1, the nano conductive carbon fiber system is obtained;

[0025] ② The polymer solvent is composed of diethylene glycol butyl ether, polyoxyethylene alkylphenyl ether, methyl benzyl alcohol, N,N-dimethylacetamide and terpineol in a mass ratio of 3:1:3:2 : 1 is added in the stirring kettle successively to form;

[0026] The binder is composed of polyester acrylic resin, water-based polyurethane resin, epoxy acrylic resin and polyurethane resin in a mass ratio of 2:3:1:1. ...

Embodiment 3

[0048] A high-density, acid-resistant and oxidation-resistant solid capacitor carbon foil production process, the process steps are as follows:

[0049] (1) Preparation of slurry:

[0050] ① Soak carbon nanotubes in a mixture of concentrated nitric acid and concentrated sulfuric acid for acidification for 1.1 h, wash with deionized water until neutral, dry to obtain acidified carbon nanotubes, then mix with carbon nanotubes evenly, acidify carbon nanotubes and press The mass ratio of carbon nanotubes to carbon nanotubes is 2:1 to obtain a nano-conductive carbon fiber system;

[0051] ② The polymer solvent is composed of diethylene glycol butyl ether, polyoxyethylene alkyl phenyl ether, and N,N-dimethylacetamide, which are sequentially added into the stirring tank according to the mass ratio of 3:1:2;

[0052] The binder is composed of polyester acrylic resin and epoxy acrylic resin in a mass ratio of 2:1, and is obtained by stirring and mixing for 30 minutes at a stirring spe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com