A kind of production method of environment-friendly size polyester for fabric sizing

A production method and environment-friendly technology, applied in the field of polyester production, can solve the problems of unstable production operation, difficult to judge the reaction end point, complex and cumbersome process, etc., and achieve the effect of simple and feasible operation, saving manpower and material resources, and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

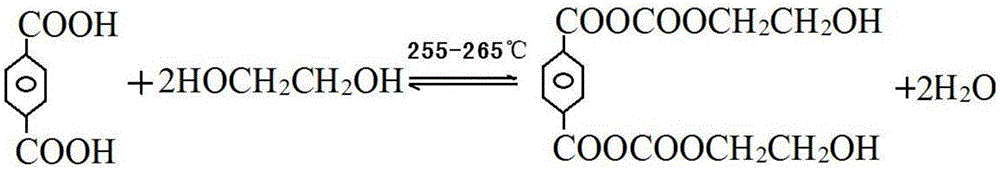

Method used

Image

Examples

Embodiment 1

[0037] A kind of production method of the environment-friendly size polyester that is used for fabric sizing of the present invention is as follows:

[0038] (1), beating

[0039] Put a certain amount of ethylene glycol (EG) into the beating kettle from the ethylene glycol head tank, and put an appropriate amount of terephthalic acid (PTA, solid) into the beating kettle evenly under stirring to make a slurry; Wherein, the mass ratio of terephthalic acid and ethylene glycol is 567:35, that is, the mass ratio of PTA and EG is 567:35.

[0040] On the pipeline from the ethylene glycol head tank to the beating kettle, another bypass is connected to the ethylene glycol flushing tank. There is a certain pressure (0.2MPa) in the ethylene glycol flushing tank. The purpose of setting up the glycol flushing tank is: When the feed pump stops feeding, press in ethylene glycol to flush the feed pump to prevent the terephthalic acid slurry from depositing in the feed pump and prevent the fe...

Embodiment 2

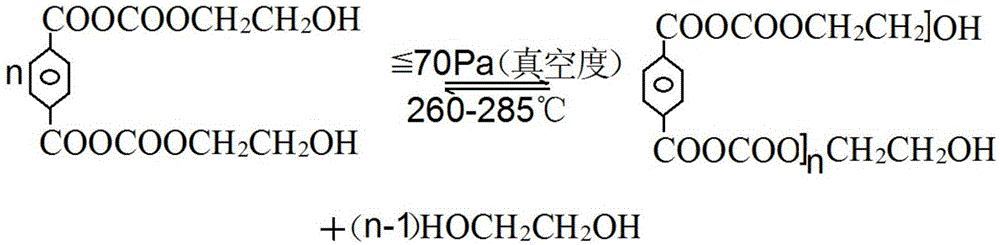

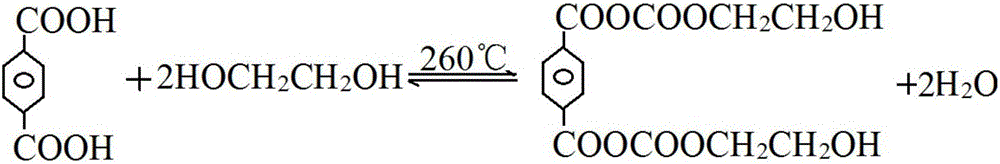

[0056] A kind of production method of the environment-friendly size polyester that is used for fabric sizing of the present invention is basically the same as embodiment 1, the difference is: the pressure in the ethylene glycol washing tank is 0.25MPa; the mass ratio of PTA and EG is 567 : 38; Esterification reaction temperature 255°C; Esterification reaction pressure: absolute pressure 75KPa; Polycondensation reaction temperature 260°C; Polycondensation reaction pressure: Vacuum degree ≤ 70Pa in low vacuum stage, vacuum degree in high vacuum stage 100Pa.

Embodiment 3

[0058] A kind of production method of the environment-friendly size polyester that is used for fabric sizing of the present invention is basically the same as embodiment 1, the difference is: the pressure in the ethylene glycol washing tank is 0.3MPa; the mass ratio of PTA and EG is 567 : 40; Esterification reaction temperature 265°C; Esterification reaction pressure: absolute pressure 90KPa; Polycondensation reaction temperature 285°C; Polycondensation reaction pressure: Vacuum degree ≤ 70Pa in low vacuum stage, vacuum degree in high vacuum stage 150Pa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com