Preparing method of super-hydrophobic coatings of condensing and heat exchange pipe and condensing heat exchange pipe

A heat exchange tube and super-hydrophobic technology, which is applied in coatings, devices for coating liquid on the surface, special surfaces, etc., can solve the problem of micro-nano structure rough surface instability hindering industrialization, limiting the industrial application of super-hydrophobic surfaces, hydrophobic Problems such as disappearance of performance, to achieve the effect of broadening industrial applications, strong weather resistance, and simple production and operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

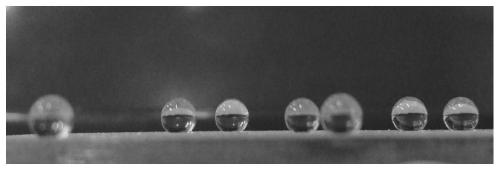

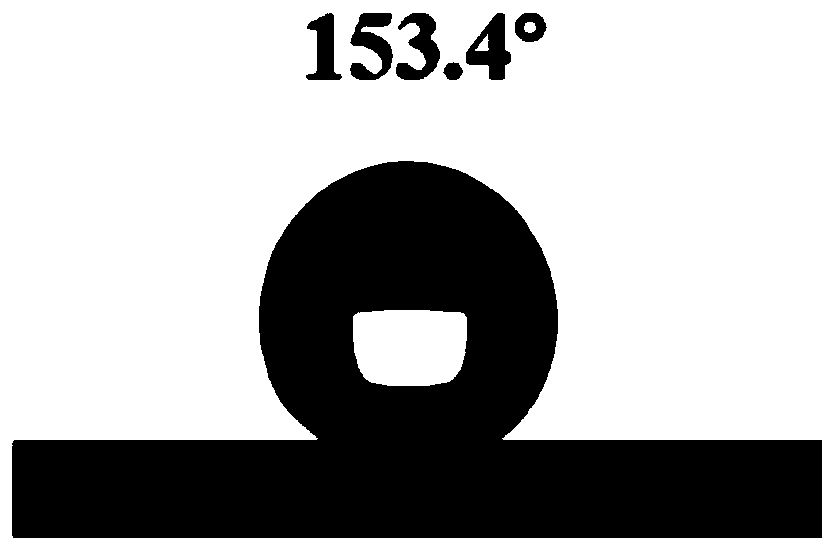

[0038] The aluminum tube is used as the base material of the heat exchange tube, and a super-hydrophobic coating is constructed on the surface of the aluminum tube. The process flow is as follows: figure 1 Shown:

[0039] Surface pretreatment of the aluminum tube: place the aluminum tube in absolute ethanol, ultrasonically clean it with an ultrasonic device for 10 minutes; rinse it with deionization, and dry it; then immerse the aluminum tube in an 80°C, 0.3mol / L NaOH solution , placed for 200 seconds; rinse with deionized water and dry. Sodium hydroxide not only reacts with the dense alumina formed on the surface of the aluminum tube, consumes the surface oxide layer, is beneficial to the generation of active hydroxyl groups on the surface of the aluminum tube, and promotes the bonding strength between the metal and the primer system or the silicone system, and at the same time A certain roughness is preliminarily constructed on the metal surface through chemical reaction. A...

Embodiment 2

[0046] The aluminum tube is used as the base material of the heat exchange tube, according to figure 1 The shown procedure constructs a superhydrophobic coating on its surface. The pretreatment process is the same as in Example 1.

[0047] Primer treatment: prepare an anilinomethyltriethoxysilane absolute ethanol solution with a mass fraction of 20%, add 2% di-n-octyltin dilaurate as a catalyst (the mass fraction of di-n-octyltin dilaurate is 2%) , fully stirred to obtain primer. The primer is sprayed onto the surface-pretreated aluminum tubes by means of a compressed air spray gun spraying method. When spraying, it is necessary to ensure that the distance between the spray gun and the substrate is 20cm, the moving speed of the spray gun is 20cm / s, spray 3 layers, and leave it to dry in an open environment after spraying.

[0048] The first spraying treatment: take 60 parts by weight of hydroxyl-terminated polydimethylsiloxane with a molecular weight of about 3000, 40 parts...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com