Positive electrode active material for lithium ion secondary batteries, method for producing the positive electrode active material for lithium ion secondary batteries, and lithium ion secondary battery

A positive electrode active material and secondary battery technology, applied in the direction of active material electrodes, secondary batteries, battery electrodes, etc., can solve problems such as helpless conduction, increase in interface resistance, damage, etc., and achieve high destructive strength and coating properties good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

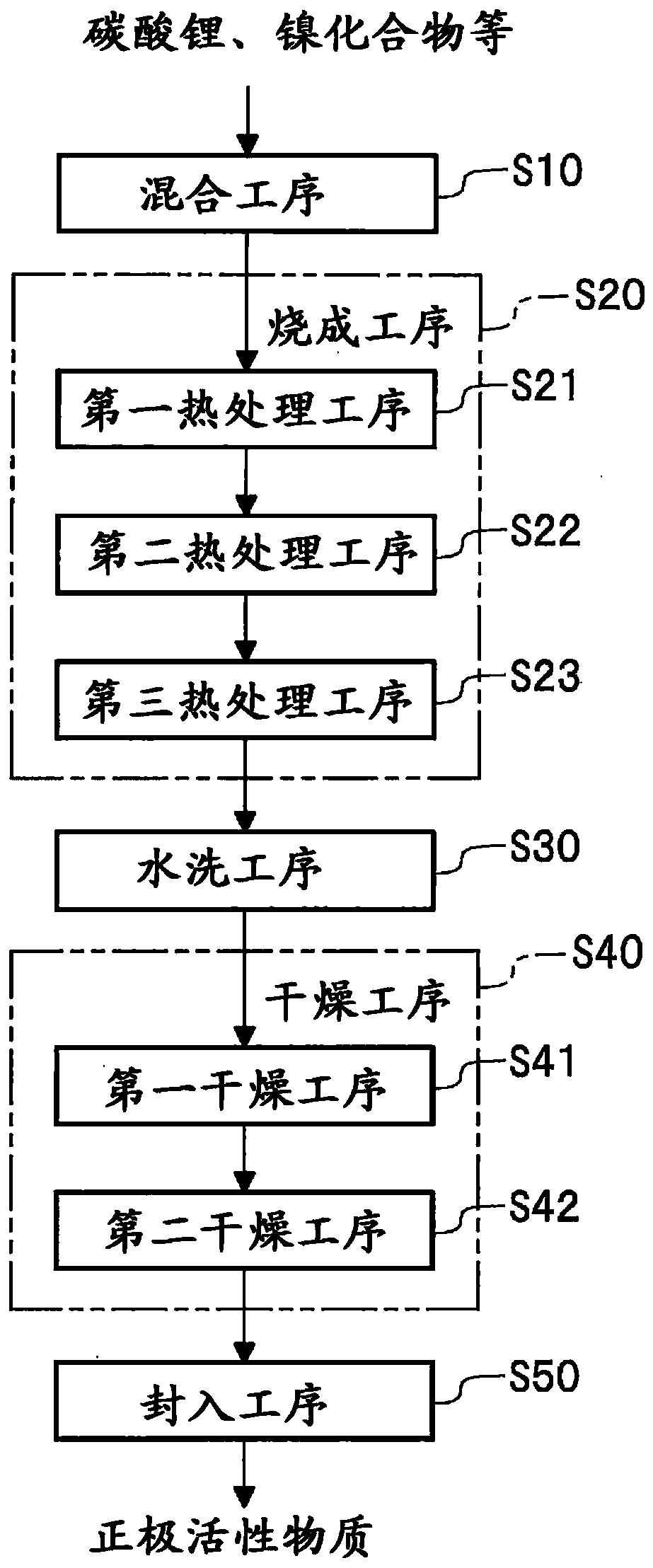

[0145] First, as starting materials, lithium carbonate, nickel hydroxide, cobalt carbonate, and manganese carbonate were prepared. Next, each raw material was weighed so that Li:Ni:Co:Mn in atomic ratio was 1.04:0.80:0.10:0.10, pulverized with a pulverizer, and wet mixed to prepare a slurry (mixing step S10).

[0146] Next, after drying the obtained slurry with a spray dryer, the dried mixture is fired to obtain fired powder of the lithium complex compound (fired step S20). Specifically, 300 g of the mixture obtained by drying the slurry was filled into an alumina container having a length of 300 mm, a width of 300 mm, and a height of 100 mm, followed by heat treatment in an atmospheric atmosphere at 350° C. for 1 hour in a continuous transport furnace to obtain a first precursor ( The first heat treatment step S21). Then, the first precursor was heat-treated at 650° C. for 4 hours in an oxygen stream in a calcining furnace replaced with an atmosphere having an oxygen concent...

Embodiment 2

[0149] A positive electrode active material was obtained in the same manner as in Example 1, except that the particle size of the positive electrode active material was changed, and the water washing step S30 and the drying step S40 were not performed.

Embodiment 3

[0151] A positive electrode active material was obtained in the same manner as in Example 2, except that the heat treatment temperature in the third heat treatment step S23 was set to 825°C.

PUM

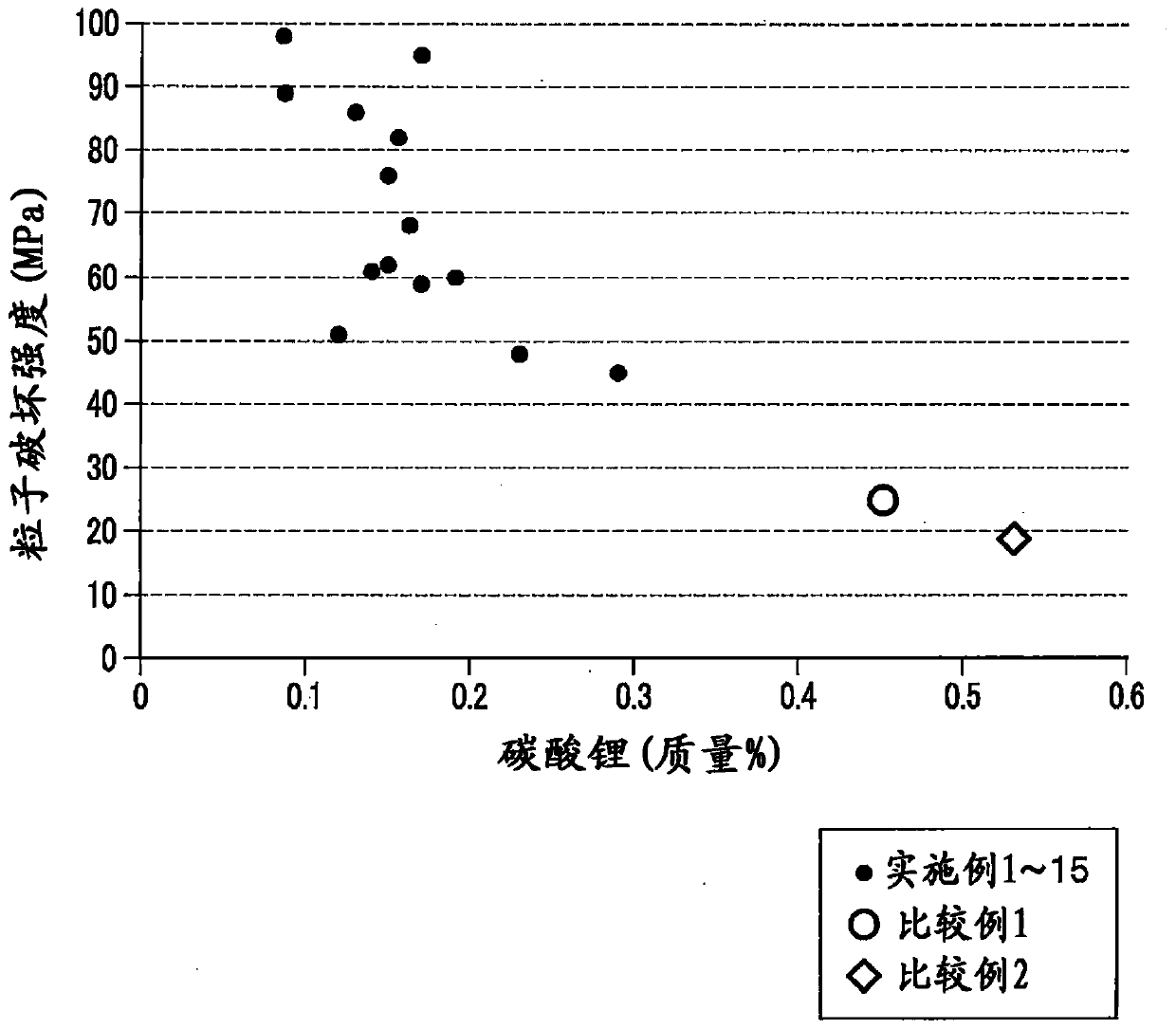

| Property | Measurement | Unit |

|---|---|---|

| fracture strength | aaaaa | aaaaa |

| fracture strength | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com