Solid-state sodium ion electrolyte, preparation method thereof and all-solid-state sodium battery

An electrolyte and sodium ion technology, applied in the field of solid-state sodium ion electrolyte and its preparation, and all-solid-state sodium battery, can solve the problems of low sodium ion conductivity, high processing cost, poor interface stability, etc., and achieves simple process and high generation efficiency. , the effect of low battery internal resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

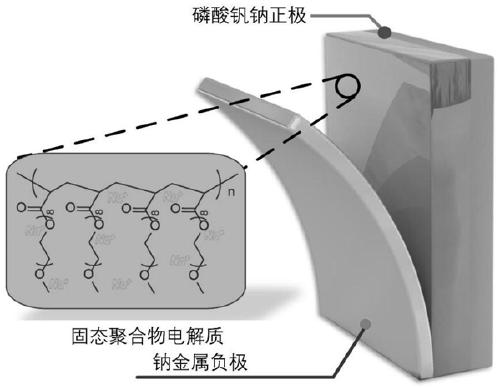

[0027] The invention provides a kind of preparation method of solid sodium ion electrolyte, comprises the following steps:

[0028] A) stirring the sodium salt, the initiator and the liquid polymer monomer under low water and low oxygen conditions to obtain a solid sodium ion electrolyte precursor slurry;

[0029] B) Under the irradiation of ultraviolet light, the slurry of the solid sodium ion electrolyte precursor is subjected to in-situ polymerization reaction to obtain a solid sodium ion electrolyte.

[0030] In the invention, the sodium salt, the initiator and the liquid polymer monomer are stirred under the condition of low water and low oxygen to obtain the solid sodium ion electrolyte precursor slurry.

[0031] Specifically, it includes: first adding sodium salt and initiator into solvent-free liquid polymer monomers, and fully stirring in a low-water and low-oxygen glove box to obtain the precursor slurry before the solid sodium ion electrolyte.

[0032] Among them, ...

Embodiment 1

[0053] 0.7g sodium vanadium phosphate (Na 3 V 2 (PO 4 ) 3 ), 0.1g conductive carbon black and 0.2g binder (PEO+NaClO 4 ) mixed and ground and stirred evenly, and coated on the surface of aluminum foil; dried in a vacuum oven at 60°C, and cut to obtain a positive electrode sheet after drying;

[0054] Then, sodium bis(fluorosulfonyl)imide (NaFSI) and polydimethylolpropionic acid (DMPA) with a mass fraction of 1% were added to the polymer monomer dimethacrylic acid (PEGDMA) without any solvent. In the solution, the molar ratio of the polymer monomer to the sodium salt was adjusted to 16:1, and it was controlled to be placed at room temperature and fully stirred to obtain a uniform polymer precursor slurry. Subsequently, move the polymer precursor slurry into a dull glove box, control the content of water and oxygen in the glove box to be lower than 0.5ppm, and then uniformly coat the polymer precursor slurry by casting method On the positive electrode sheet, thereby filling...

Embodiment 2

[0057] Sodium bis(fluorosulfonyl)imide (NaFSI) and polydimethylolpropionic acid (DMPA) with a mass fraction of 1% were added to the polymer monomer dimethacrylic acid (PEGDMA) solution without any solvent , adjust the molar ratio of the polymer monomer to the sodium salt to be 22:1, place it at room temperature and stir thoroughly to obtain a uniform polymer precursor slurry. Subsequently, move the polymer precursor slurry into a glove box with an ultraviolet light source, control the water and oxygen content in the glove box to be lower than 0.5ppm, then cast the polymer precursor slurry on a polytetrafluoroethylene plate, The polymer electrolyte precursor was solidified and polymerized under ultraviolet light irradiation, and after 20 minutes of ultraviolet light irradiation at a temperature of 30° C., a sodium ion solid sodium ion electrolyte film with a thickness of about 150 μm was obtained.

[0058] Test the ionic conductivity of the prepared solid sodium ion electrolyte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Ionic conductivity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com