Electrolyte for ultralow-temperature aluminum electrolytic capacitor and preparation method of electrolyte

An aluminum electrolytic capacitor, ultra-low temperature technology, applied in the direction of electrolytic capacitors, capacitor manufacturing, capacitors, etc., can solve the problems of small capacity of aluminum electrolytic capacitors, failure to start electrical appliances, easy to corrode sealing rubber, etc., to achieve low cost, less heat generation, The effect of reducing self-consumption energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

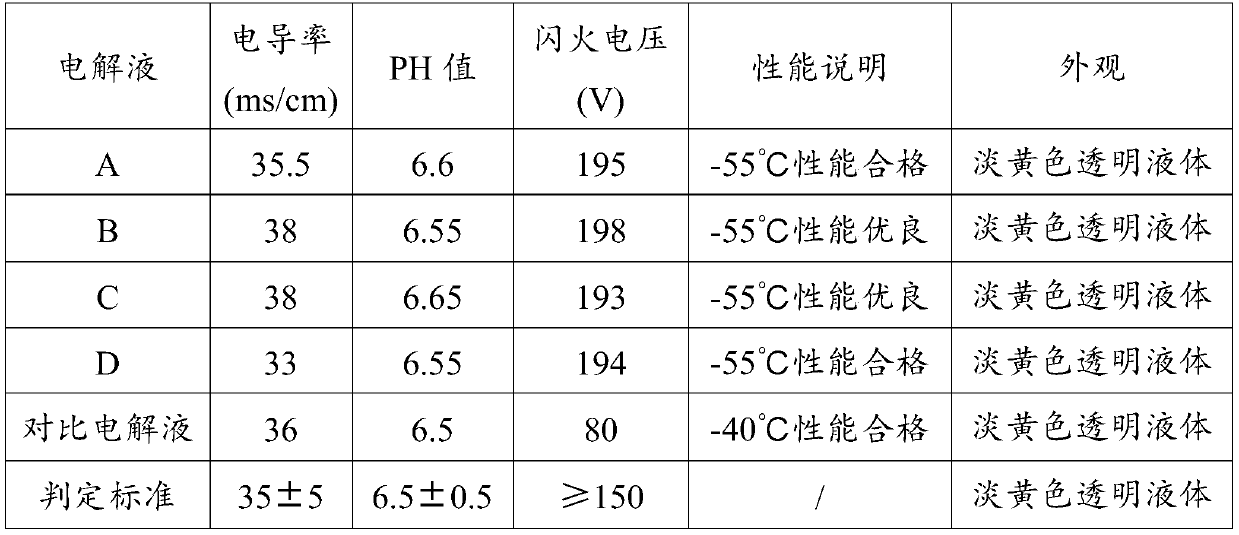

Examples

Embodiment 1

[0032] like figure 1 Shown, in order to prepare the electrolytic solution that above-mentioned ultra-low temperature aluminum electrolytic capacitor is used, its preparation method is as follows:

[0033] S1: Mix the first solvent and the second solvent evenly, and heat to 40-65°C, and keep the temperature for 5-15min;

[0034] S2: Add a third solvent to the mixed solution in S1, heat to 75-90°C, and keep the temperature constant for 20-40min;

[0035] S3: Then add the solute and high-temperature stabilizer, and heat to 100-110°C, and keep the temperature constant for 50-70min;

[0036] S4: Cool down to 80-90°C, add hydrogen remover, and keep the temperature constant for 25-35min;

[0037] S5: Lower the temperature to below 60°C to obtain an ultra-low temperature electrolyte.

[0038] That is, mix 40-50% ethylene glycol and 20-30% water, heat to 50°C and keep it for 10 minutes; then add 5-10% sulfolane, continue to heat to 85°C, keep it for 30 minutes; then add 8-15% ammoni...

Embodiment 2

[0041] Mix 43% ethylene glycol and 22% water, heat to 50°C and keep it warm for 10 minutes; then add 8% 1,2-propanediol, continue heating to 85°C, keep warm for 30 minutes; then add 13% ammonium adipate, 2% hexadiene Acid, 4% mannitol, 1% citric acid, 1.5% diammonium hydrogen phosphate, 2% ammonium succinate, 2% ammonium formate, continue heating to 105°C, keep warm for 60min; then cool down to 85°C, add 1.5% Ammonium nitrobenzoate, keep warm for 30 minutes; finally, continue to cool down to below 60°C to obtain ultra-low temperature electrolyte B.

Embodiment 3

[0043] Mix 45% ethylene glycol and 25% water, heat to 50°C and keep it for 10 minutes; then add 9% ethylene glycol monomethyl ether, continue to heat to 85°C, keep it for 30 minutes; then add 8% ammonium adipate, 1.5% adipate Diacid, 3% mannitol, 1.5% citric acid, 2% diammonium hydrogen phosphate, 3% ammonium succinate, 2% ammonium formate, continue heating to 105°C, keep warm for 60min; then cool down to 85°C, keep warm for 30min; Finally, continue to lower the temperature to below 60°C to obtain ultra-low temperature electrolyte C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com