Two-dimensional lamellar phase enhanced silver-based electric contact material and preparation method thereof

A technology of electrical contact materials and two-dimensional sheets, applied in contacts, circuits, electrical switches, etc., can solve problems such as high toxicity, burning loss, and inability to transmit heat to electrical contacts in time, achieving small changes in resistivity, The effect of improving thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

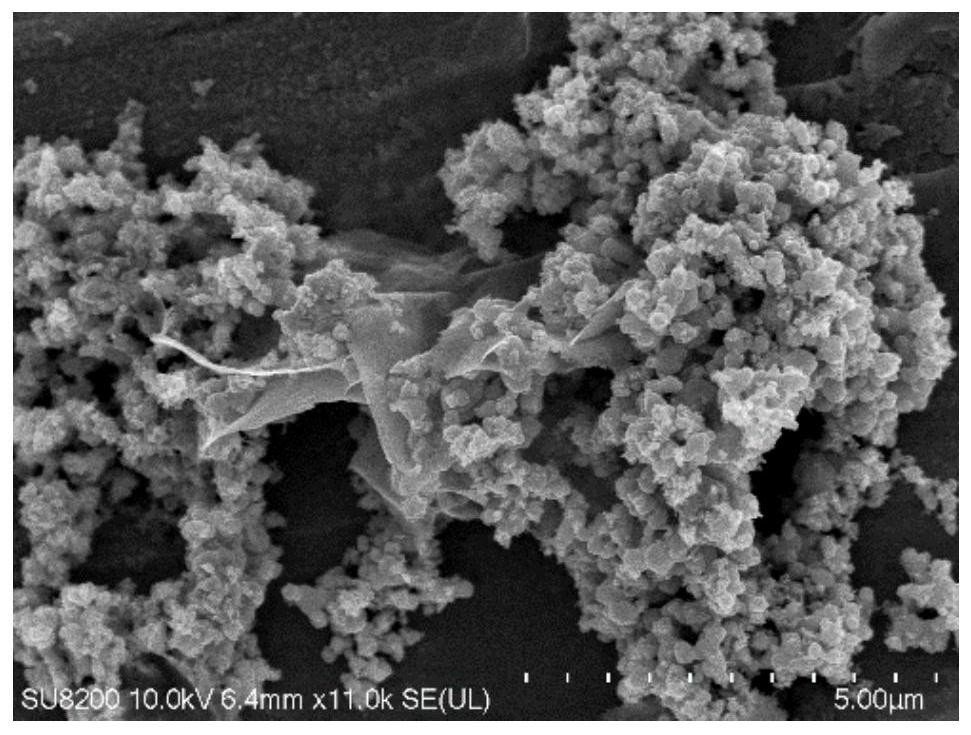

[0034] (1) Graphite oxide was prepared by the Hummers method using flake graphite as raw material, and then a well-dispersed 0.5 mg / mL graphene oxide solution was obtained after ultrasonication for 10 h.

[0035] (2) Take 3.3974g of silver nitrate and add 9.31mL of graphene oxide solution, then add deionized water to 100mL, mix with low-temperature ultrasonic and mechanically stir for 30min to complete the electrostatic adsorption self-assembly.

[0036] (3) Take 0.88g of sodium hydroxide and add 100mL of water, stir evenly, drop into the above mixed salt solution, the dropping speed is 3mL / min, and the whole process is supplemented by 800r / min mechanical stirring.

[0037] (4) After three times of washing and suction filtration, the precipitate was dried in vacuum at 50°C for 12 hours. The composite material powder was ground, pressed at 550MPa for 90s, and then placed in a vacuum furnace for sintering. The sintering parameters were kept at 750°C for 3 hours to obtain silver. ...

Embodiment 2

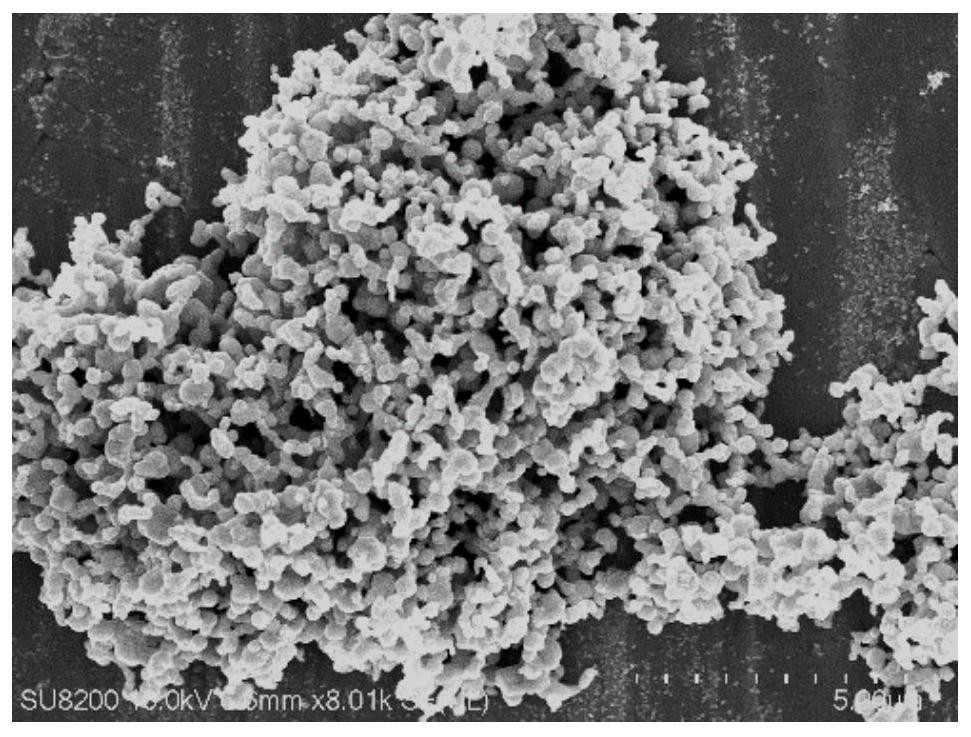

[0039] (1) Graphite oxide was prepared by the Hummers method using flake graphite as raw material, and then a well-dispersed 5 mg / mL graphene oxide solution was obtained after ultrasonication for 10 h.

[0040] (2) Take 3.3974g of silver nitrate and add 37.52mL of graphene oxide solution, then add deionized water to 100mL, mix with low-temperature ultrasonic and mechanically stir for 30min to complete electrostatic adsorption self-assembly.

[0041] (3) Take 0.88g of sodium hydroxide and add 100mL of water, stir evenly, drop into the above mixed salt solution, the dropping speed is 4mL / min, and the whole process is supplemented by 750r / min mechanical stirring.

[0042] (4) The precipitate was washed and filtered three times, then vacuum-dried at 50°C for 12 hours, the composite material powder was ground, pressed at 550MPa for 90s, and then placed in a nitrogen atmosphere for sintering. The sintering parameters were kept at 850°C for 3 hours to obtain silver base electrical co...

Embodiment 3

[0044] (1) Graphite oxide was prepared by the Hummers method using flake graphite as raw material, and then a well-dispersed 5 mg / mL graphene oxide solution was obtained after ultrasonication for 10 h.

[0045] (2) Take 1.6987g of silver nitrate and add 6.62mL of graphene oxide solution, then add deionized water to 100mL, mix with low-temperature ultrasonic and mechanically stir for 30min to complete the electrostatic adsorption self-assembly.

[0046](3) Take 0.44g of sodium hydroxide and add 100mL of water, stir evenly, drop into the above mixed salt solution, the dropping speed is 3mL / min, and the whole process is supplemented by 750r / min mechanical stirring.

[0047] (4) The sediment was washed and filtered three times, then dried in vacuum at 50°C for 12 hours, the composite material powder was ground, pressed at 550MPa for 90s, and then placed in a vacuum furnace for sintering at 750°C for 3 hours to obtain silver-based electrical contact material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com