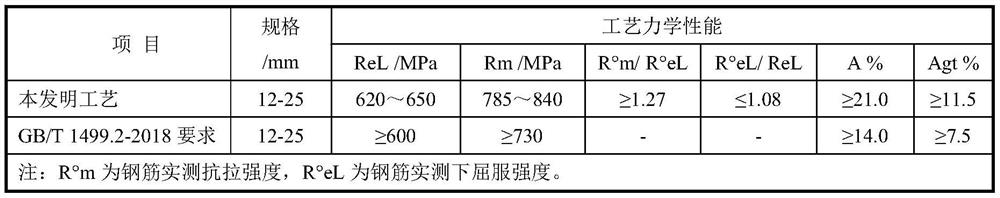

A preparation method of nitrogen-enriched vanadium microalloyed hrb600 ultrafine grain anti-seismic steel bar

A technology of ultra-fine grained and seismic steel bars, applied in the metallurgical field, can solve the problems of high price of vanadium-nitrogen alloys, high production costs, unfavorable production costs of HRB600 high-strength steel bars, and the improvement of market competitiveness of products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

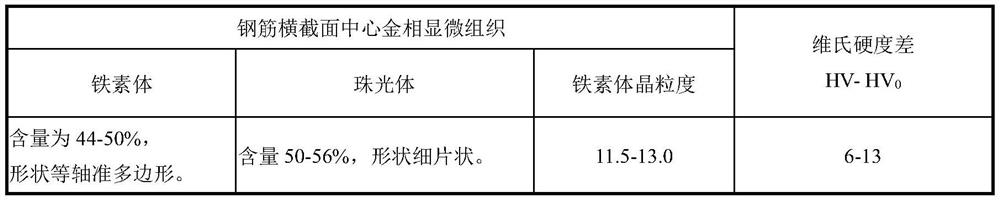

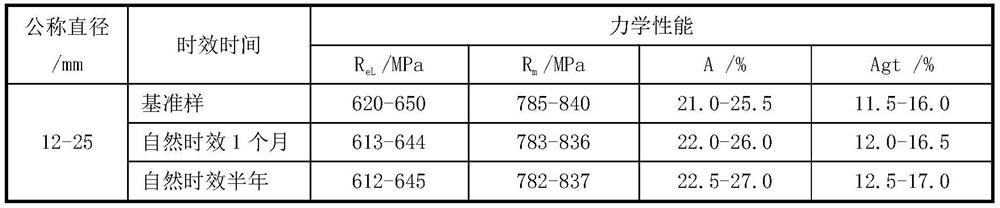

Examples

preparation example Construction

[0020] The preparation method of nitrogen-rich vanadium microalloyed HRB600 ultra-fine grain anti-seismic steel bar of the present invention specifically comprises the following steps:

[0021] A. Molten steel smelting: scrap steel, pig iron and molten iron at 130-160kg / t respectively 钢 、20kg / t 钢 、900-930kg / t 钢 The ratio is added to the LD converter, and then the conventional top-bottom composite blowing is carried out, and conventional lime, light-burned dolomite, and magnesite ball slagging are added. The amount of lime added is 25-30kg / t steel, and the amount of light-burned dolomite added is 12 -18kg / t steel, the amount of magnesite balls added is 1.0kg / t steel, the carbon content at the control end point is ≥0.06wt%, the tapping temperature is ≤1630°C; the ladle before tapping is 6.0kg / t 钢 Add the following mass ratio of vanadium-containing pig iron: composition C 3.5wt%, Si 0.40wt%, Mn 0.65wt%, V 1.00-1.20wt%, P0.205wt%, S 0.075wt%, the rest is Fe and not Impurities t...

Embodiment 1

[0040] A. Molten steel smelting: 130kg / t respectively 钢 、20kg / t 钢 The cold material load proportioning, adds the steel scrap (chemical composition: C 0.12wt%, Si 0.20wt%, Mn 0.45wt%, P 0.025wt%, S 0.020wt% in LD converter, all the other are Fe and Inevitable impurities) and pig iron (chemical composition: C3.0wt%, Si 0.30wt%, Mn 0.45wt%, P0.070wt%, S 0.020wt%, the rest is Fe and unavoidable impurities); Then press 930kg / t 钢The molten iron is loaded into the ratio, and the following temperature and mass ratio of molten iron are added to the LD converter: molten iron temperature 1280 ° C, molten iron composition C 4.4wt%, Si0.25wt%, Mn 0.45wt%, P 0.075wt%, S 0.020wt% , the rest is Fe and unavoidable impurities; scrap steel, pig iron and molten iron are blended into the LD converter, then conventional top-bottom composite blowing is carried out, and conventional lime, lightly burned dolomite and magnesite balls are added to make slag, and the amount of lime added is 25kg / t of ...

Embodiment 2

[0054] A, molten steel smelting: according to 145kg / t steel, the cold charge of 20kg / t steel is loaded into proportion respectively, in LD converter, add the steel scrap of following mass ratio (chemical composition: C 0.18wt%, Si 0.27wt%, Mn 0.55wt% %, P 0.035wt%, S0.032wt%, the rest are Fe and unavoidable impurities) and pig iron (chemical composition: C3.2wt%, Si 0.40wt%, Mn0.57wt%, P 0.080wt%, S 0.030wt%, the rest is Fe and unavoidable impurity); after that, according to the proportion of 915kg / t steel molten iron, add the following temperature and mass ratio of molten iron in the LD converter: the temperature of molten iron is 1300°C, and the composition of molten iron is C4. 5wt%, Si 0.37wt%, Mn 0.58wt%, P 0.092wt%, S 0.030wt%, the rest is Fe and unavoidable impurities; scrap steel, pig iron and molten iron are mixed into the LD converter, and the conventional top-bottom compounding is carried out Blowing, adding conventional lime, light-burned dolomite, magnesite balls ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com