High-steel-grade corrosion-resistant sleeve and preparation method thereof

A technology of anti-corrosion and casing, which is applied in the field of high-grade corrosion-resistant casing and its preparation, and can solve the problems of increasing product cost and final cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

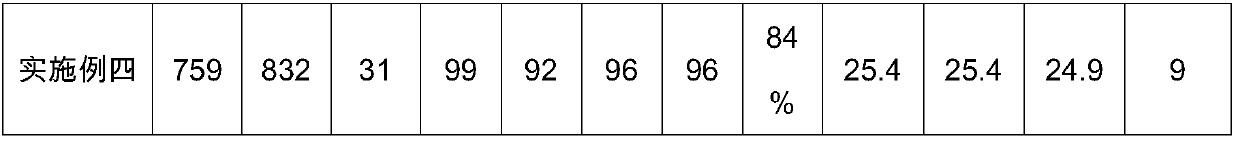

Examples

Embodiment 1

[0030] A high-grade steel-grade corrosion-resistant casing, which includes a pipe body, the components contained in the pipe body and the mass percentages of each component are as follows: C: 0.27%; Si: 0.15%; Mn: 0.55%; P: 0.005% ; S: 0.001%; Cr: 0.45%; Ni: 0.05%; Cu: 0.05%; Mo: 0.82%; V: 0.05%; Nb: 0.02%; Al: 0.01%; Total: 100%.

[0031] The steps of the preparation method of the high-grade steel-grade corrosion-resistant sleeve include:

[0032] (1) Forming a tube billet: smelting through a converter according to the mass percentage ratio of each component and each component, and performing continuous casting and rolling of the molten steel after converter smelting to form a tube billet;

[0033] (2) Pipe billet sawing: the pipe billet is sawed and processed to form a plurality of divided pipe billets;

[0034] (3) Annular furnace heating: put the divided tube billet into the annular furnace for heating;

[0035] (4) Perforation: use a perforator to perforate the heat-...

Embodiment 2

[0049] A high-grade steel-grade corrosion-resistant casing, which includes a pipe body, the components contained in the pipe body and the mass percentages of each component are as follows: C: 0.32%; Si: 0.35%; Mn: 0.40%; P: 0.012% ; S: 0.003%; Cr: 0.60%; Ni: 0.10%; Cu: 0.10%; Mo: 0.92%; V: 0.09%; ; N: 0.008%; the rest is iron and unavoidable impurities, total: 100%.

[0050] The preparation method of the high-grade steel-grade corrosion-resistant casing of this embodiment is the same as that of Embodiment 1.

[0051] The dimensions of the prepared high-grade steel-grade corrosion-resistant casing are as follows: the outer diameter of the pipe body is between 199.8 mm and 202 mm; the ellipticity of the pipe body is 0.8 mm; the wall thickness of the pipe body ranges from 10.5 mm~10.8mm; the curvature of the pipe body is ≤1.2mm / m, and the chord height within 1.8m of the pipe end is ≤2.0mm, and the full-length chord height of the pipe body is ≤12.0mm, meeting the size requirement...

Embodiment 3

[0053] A high-grade steel-grade corrosion-resistant casing, which includes a pipe body, the components contained in the pipe body and the mass percentages of each component are as follows: C: 0.3%; Si: 0.25%; Mn: 0.5%; P: 0.006% ; S: 0.0015%; Cr: 0.5%; Ni: 0.05%; Cu: 0.05%; Mo: 0.86%; V: 0.07%; ; N: 0.004%; the rest is iron and unavoidable impurities, total: 100%.

[0054] The preparation method of the high-grade steel-grade corrosion-resistant casing of this embodiment is the same as that of Embodiment 1.

[0055] The dimensions of the prepared high-grade steel-grade corrosion-resistant casing are as follows: the outer diameter of the pipe body is between 201mm and 202mm; the ellipticity of the pipe body is 0.2mm; the wall thickness of the pipe body ranges from 10.8mm to 10.92mm; the curvature of the pipe body is ≤1.2mm / m, and the chord height within 1.8m of the pipe end is ≤2.0mm, and the full-length chord height of the pipe body is ≤12.0mm, meeting the size requirements. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Eccentricity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com