Emulsified cutting fluid and preparation method thereof

A cutting fluid and emulsified technology, applied in the field of emulsified cutting fluid and its preparation technology, to achieve good lubricating performance and cooling performance, solve the problem of damage, and simple production and preparation technology.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

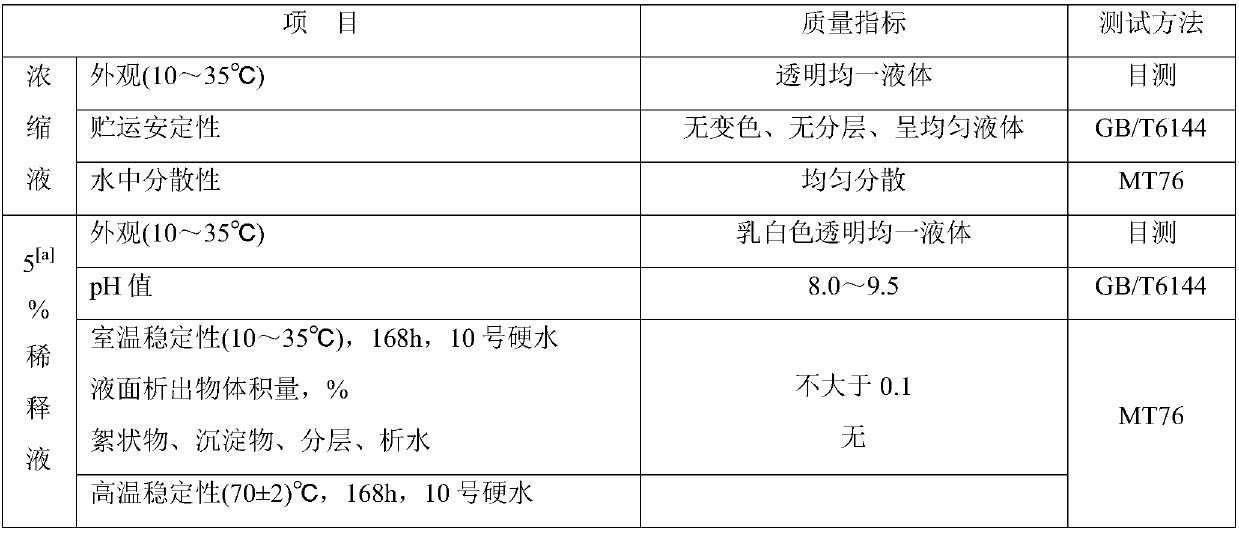

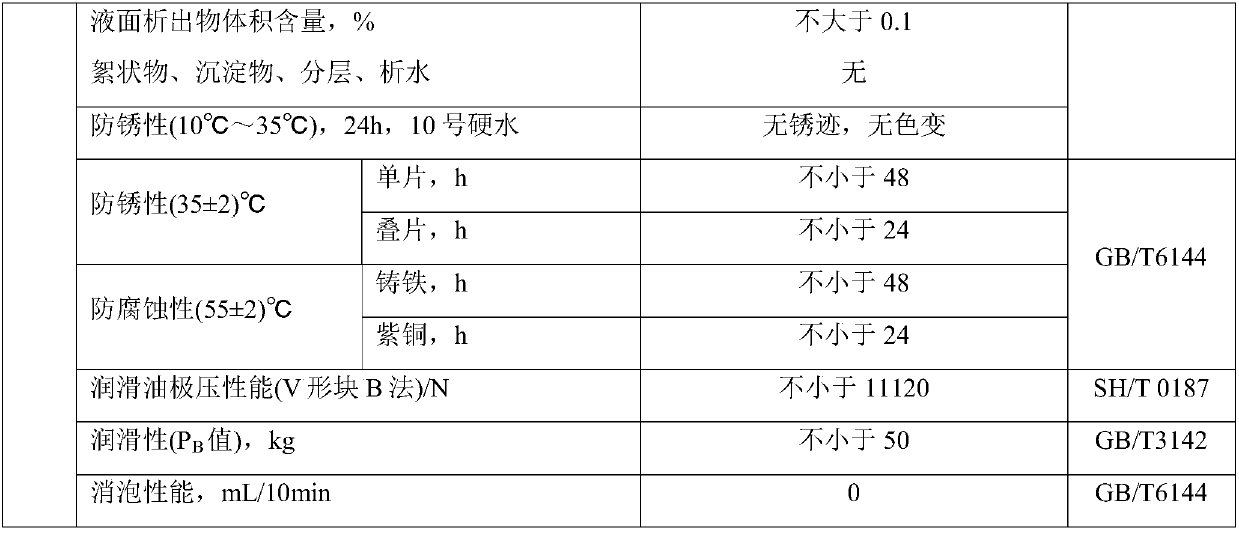

Image

Examples

preparation example Construction

[0099] Preparation method of emulsified cutting fluid, system temperature control

[0100] In the present invention, the temperature control of the system is not particularly limited, usually at 10-35°C, first add rust inhibitors and preservatives during softening, and then add organic alcohol amines, base oils, surfactants, and composite lubricants in sequence , bactericide, anti-hard water agent, finally add anti-foaming agent, stir until the system is uniform and clear to obtain the emulsified cutting fluid;

[0101] If the system temperature is less than 10°C, it is easy to cause difficulty in stirring due to the low temperature of the system, and the emulsified oil will become unstable; while the temperature of the system is greater than 35°C, due to the high temperature of the system, the water will volatilize seriously during the stirring process, and the mass fraction will not be stable. Accurate, etc., with no other beneficial effects.

Embodiment 1

[0103] An emulsified cutting fluid and its preparation process, each component, weight percentage and preparation process are:

[0104] The base oil is KR2832 40%, MVI150 14%, the surfactant is polyisobutylene succinamide 6.7%, fatty acid polyoxyethylene ester 2.5%, sorbitan oleate 6%, and the antirust agent is sodium nitrite 1.5%, undecanedibasic acid 0.9%, sodium benzoate 0.7%, preservative benzotriazole 0.3%, composite lubricants were tall oil fatty acid 2.2%, polymer ester 1.8%, organic alcohol amines were Triethanolamine 9%, monoethanolamine 0.5%, fungicide morpholine 1.5%, isothiazolinone compounds 0.8%, anti-hard water agent long-chain alcohol ether carboxylic acid 2.0%, short-chain alcohol ether carboxylic acid 1.3%, anti-hardening agent The foaming agent is 0.1% of silicone defoamer and 8.2% of demineralized water.

[0105] The preparation process is: at room temperature (10-35°C), add 0.3% benzotriazole, 0.7% sodium benzoate, 1.5% sodium nitrite, 0.9% undecanedibasi...

Embodiment 2

[0107] An emulsified cutting fluid and its preparation process, each component, weight percentage and preparation process are:

[0108] The base oil is 50% of No. 25 transformer oil, the surfactants are sodium petroleum sulfonate 6.5%, isotridecyl alcohol polyoxyethylene ether 2%, sorbitan oleate 16%, and the rust inhibitor is molybdic acid 0.5% sodium, 1% dodecenyl succinic acid, 0.2% methyl benzotriazole derivative as preservative, 2% tall oil fatty acid, 1% dialkyl sulfide as compound lubricant, organic Alcohol amines are triethanolamine 7%, diglycolamine 1.5%, bactericide is morpholine 2%, antihard water agent is mixed alcohol ether carboxylic acid 3.5%, antifoaming agent is siloxane defoamer 0.1%, Softened water 6.7%.

[0109] The preparation process is: at room temperature (10-35°C), add 0.2% of tolyltriazole derivatives, 0.5% of sodium molybdate, 7% of triethanolamine, and 1.5% of diglycolamine into 6.7% of demineralized water , Stir evenly, and then add 50% of No. 25...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com