Full-area rubber ball cleaning system for condenser

A technology for cleaning systems and condensers, which is applied in the directions of cleaning heat transfer devices, cleaning of non-rotating equipment, lighting and heating equipment, etc., and can solve the problems of clogging of ball nets and large differences in the degree of contamination of cooling pipes of condensers. To prevent filter clogging, improve ball collection rate, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0071] Specific embodiments of the present invention will be described in detail below.

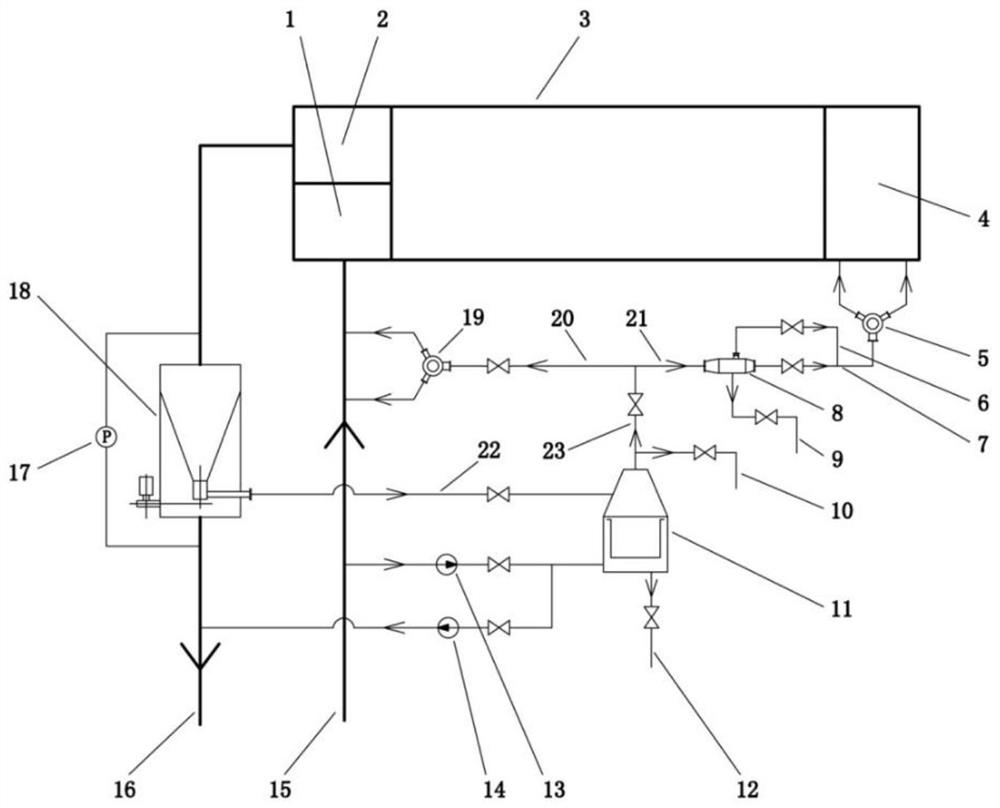

[0072] Such as figure 1 As shown, a condenser full-area rubber ball cleaning system includes a ball server 11, a ball collector 18, a ball collector 8, a ball pump 13, a ball collector pump 14, a first manifold 19, a second manifold Device 5, total serving pipeline 23, the first serving pipeline 20, the second serving pipeline 21, the ball receiving pipeline 22, the ball exhaust pipeline 10, the ball discharge pipeline 12, the ball collector drainage pipeline 6. The sewage pipeline 9 of the ball collector and the electrical control cabinet, in which:

[0073] One end of the condenser 3 is respectively provided with a condenser water inlet chamber 1 and a condenser water return chamber 2, and the other end of the condenser 3 is provided with a condenser rotary water chamber 4;

[0074] The condenser water inlet chamber 1 is connected with the circulating water inlet pipeline 15;

[0075...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com