Preparation method of aqueous rusty convertible anticorrosive paint

A technology of anti-corrosion paint and production method, applied in the direction of anti-corrosion paint and coating, can solve the problems of poor decoration and poor water resistance, and achieve the effect of good rust and anti-corrosion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A water-based rust conversion anti-corrosion coating:

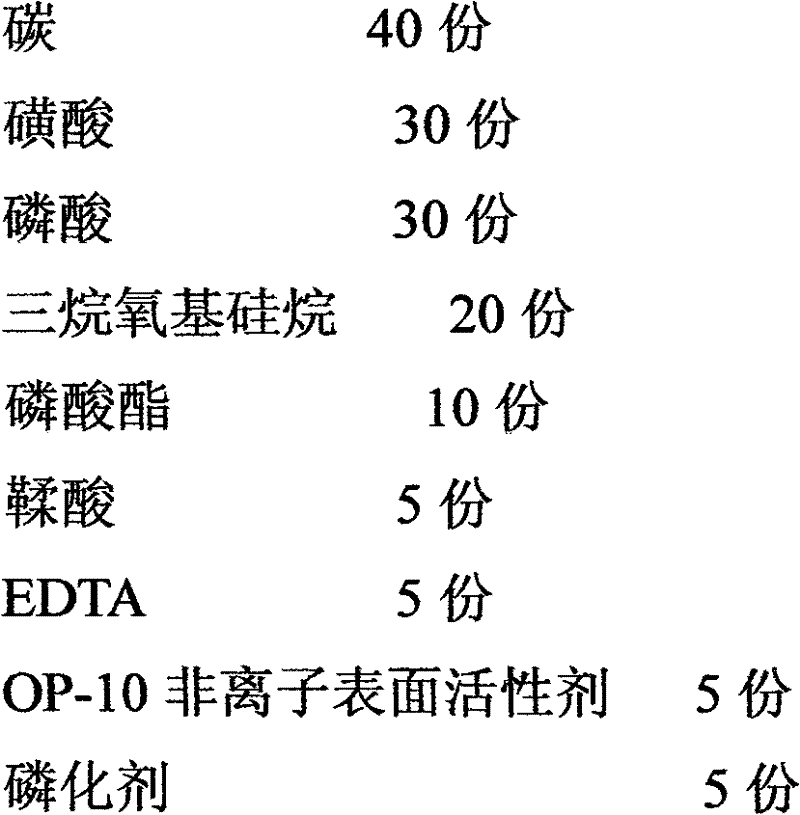

[0029] 1. Raw material formula

[0030] Carbon 40 parts

[0031] 30 parts of sulfonic acid

[0032] Phosphoric acid 30 parts

[0033] Trialkylsilane 20 parts

[0034] Phosphate 10 parts

[0035] Tannic acid 5 parts

[0036] EDTA 5 parts

[0037] OP-10 nonionic surfactant 5 parts

[0038] Phosphating agent 5 parts

[0039] 2. And prepare according to the following process steps and process parameters:

[0040] (1) Solvothermal carbonization and acidification to prepare nano-solid carbon sulfonic acid and carbon phosphoric acid.

[0041] (2) Use the polyhydroxyl surface of the carbon material to react with trialkoxysilane for modification.

[0042] (3) Phosphate, tannic acid, EDTA and other complex organic compounds are used as penetration enhancers.

[0043] (4) Use OP-10 and other non-ionic surfactants to emulsify and disperse the metal surface oil in the material to achieve the purpose of oil use, and t...

Embodiment 2

[0045] A water-based rust conversion anti-corrosion coating:

[0046] 1. Raw material formula

[0047] Carbon 50 parts

[0048] Sulfonic acid 20 parts

[0049] Phosphoric acid 20 parts

[0050] Trialkylsilane 15 parts

[0051] Phosphate 7 parts

[0052] Tannic acid 7 parts

[0053] EDTA 7 parts

[0054] OP-10 nonionic surfactant 5 parts

[0055] Phosphating agent 5 parts

[0056] 2. And prepare according to the following process steps and process parameters:

[0057] (1) Solvothermal carbonization and acidification to prepare nano-solid carbon sulfonic acid and carbon phosphoric acid.

[0058] (2) Use the polyhydroxyl surface of the carbon material to react with trialkoxysilane for modification.

[0059] (3) Phosphate, tannic acid, EDTA and other complex organic compounds are used as penetration enhancers.

[0060] (4) Use OP-10 and other non-ionic surfactants to emulsify and disperse the metal surface oil in the material to achieve the purpose of oil use, and then ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com