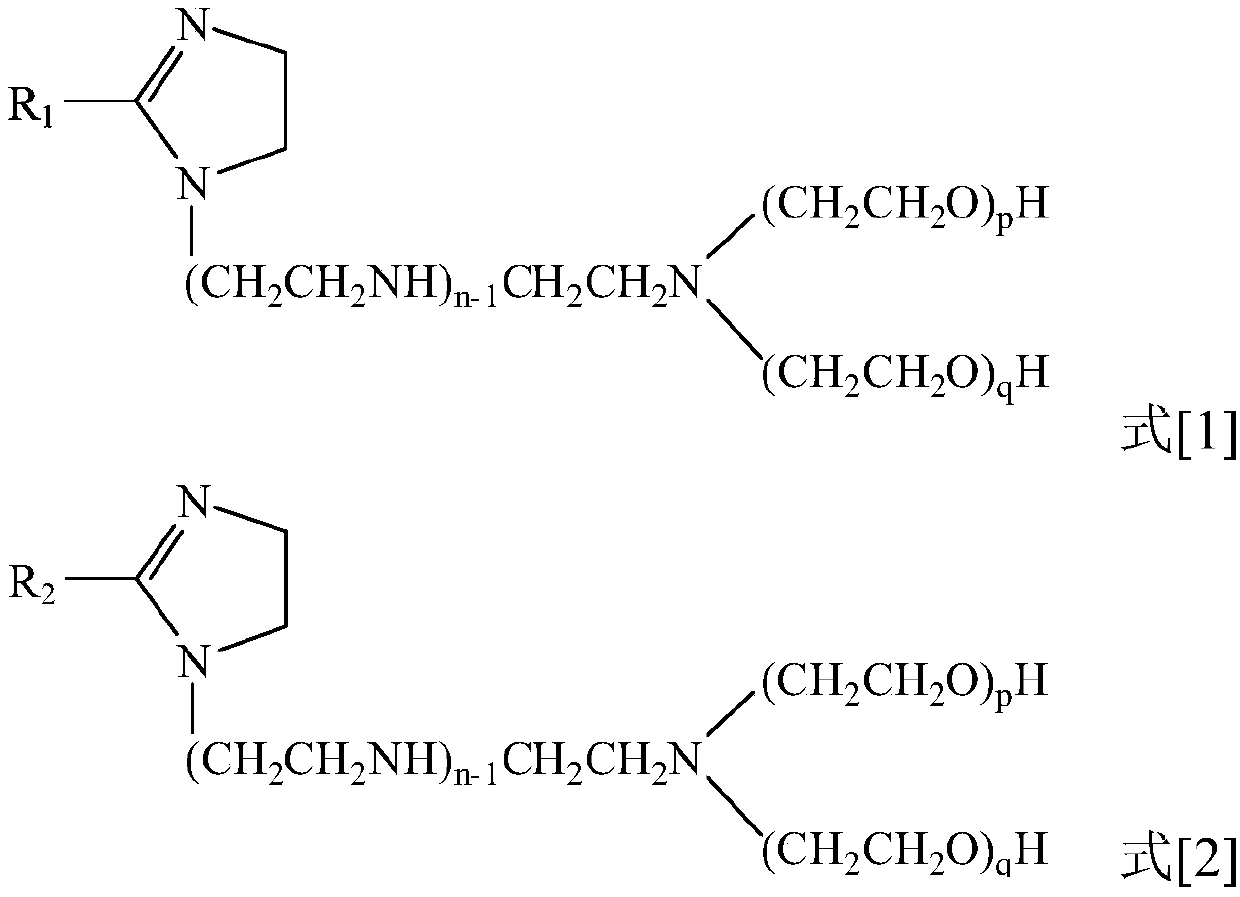

Imidazoline polyoxyethylene ether corrosion inhibitor for oil collection and transmission pipeline and preparation method of corrosion inhibitor

A technology of imidazoline polyoxyethylene ether and acid imidazoline polyoxyethylene ether is applied in the field of petroleum and petrochemical gathering pipelines and equipment protection, and can solve the problems of formaldehyde and benzaldehyde, such as irritating odor, being difficult to obtain, and inactivating, and achieving enhanced Corrosion inhibition effect, easy control, firm film formation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0064] The present invention also provides a preparation method of any one of the above-mentioned corrosion inhibitors, comprising the following process:

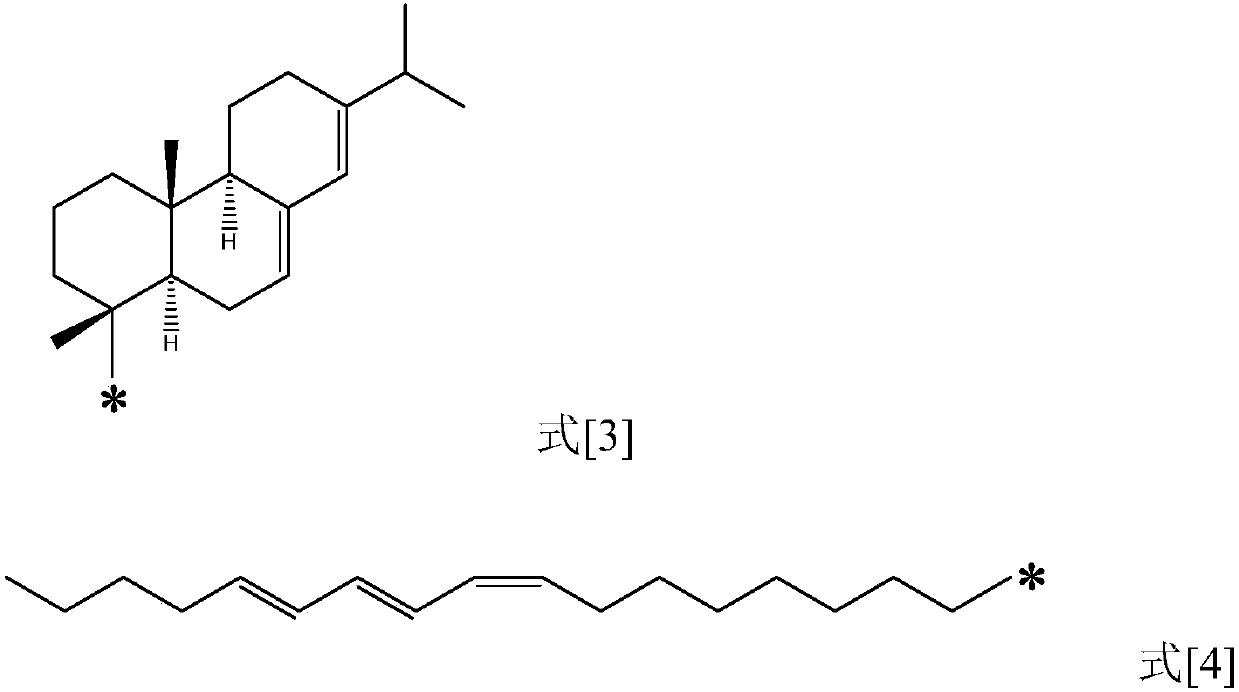

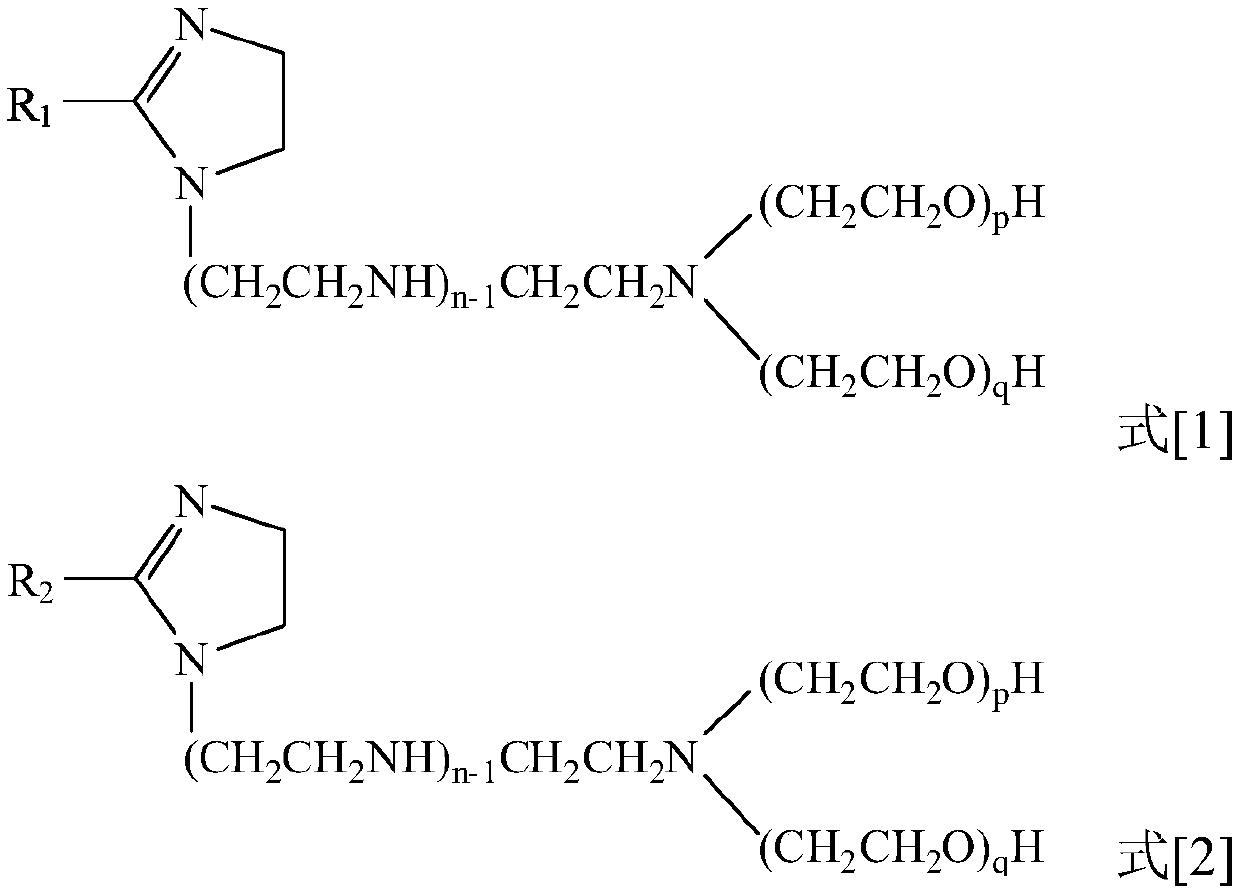

[0065] Mix oleic acid and abietic acid with polyamines to undergo amidation reaction, and keep the amidation product system at 170-220°C for more than 1 hour to obtain a reaction intermediate system with an acid value of less than 5 mg / kg;

[0066] Feed ethylene oxide into the reaction intermediate system to react to obtain the main agent;

[0067] At room temperature, mix the main agent and the compound and stir evenly to obtain the corrosion inhibitor;

[0068] or,

[0069] Using oleic acid and abietic acid to mix with polyamines to undergo amidation reaction, and keep the amidation product system at 170-220°C for more than 1 hour to obtain two reaction intermediate systems with an acid value of less than 5 mg / kg;

[0070] Feed ethylene oxide into the two reaction intermediate systems to react respectively, and mix the ...

Embodiment 1

[0090] The preparation method of the corrosion inhibitor of the present embodiment comprises the steps:

[0091] 1) Add the mixed acid and hydroxyethylethylenediamine into the reaction kettle at a molar ratio of 1:1.4, then add xylene water-carrying agent (10% of the total material), heat and stir to raise the temperature to 150-160°C and keep it warm for 3 hours, the heating rate is not higher than 20°C / 10m2n; wherein, the mixed acid includes oleic acid and abietic acid, and the molar ratio of oleic acid to abietic acid is 1:4;

[0092] During the reaction, water flows out from the reactor top condensing pipe, and what is generated at this time is the amide of oleic acid and the amide of abietic acid;

[0093] 2) Continue to heat up to 170-180°C, after 1.5 hours of reaction, continue to heat up to 210-220°C, keep warm at this temperature for 4 hours, the heating rate is not higher than 20°C / 10m2n, and then release a molecule of water to undergo a cyclization reaction; If the...

Embodiment 2

[0099] The preparation method of the corrosion inhibitor of the present embodiment comprises the steps:

[0100] 1) Add the mixed acid and hydroxyethylethylenediamine into the reaction kettle at a molar ratio of 1:1.3, then add xylene water-carrying agent (10% of the total material), heat and stir to 150-160°C and keep warm for 3 Hours, the heating rate is not higher than 20°C / 10m2n; wherein, the mixed acid includes oleic acid and abietic acid, and the molar ratio of oleic acid to abietic acid is 3:7;

[0101] During the reaction, water flows out from the reactor top condensing pipe, and what is generated at this time is the amide of oleic acid and the amide of abietic acid;

[0102] 2) Continue to heat up to 170-180°C, after 1.5 hours of reaction, continue to heat up to 210-220°C, keep warm at this temperature for 4 hours, the heating rate is not higher than 20°C / 10m2n, and then release a molecule of water to undergo a cyclization reaction; If the acid value of the detection...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com