Method for preparing TC4 titanium alloy parts through powder injection molding

A powder injection molding, titanium alloy technology, applied in the field of titanium alloy parts processing, can solve the problems of restricted application, poor plasticity, high impurity content, and achieve the effects of being beneficial to mass production, low cost, and high production accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

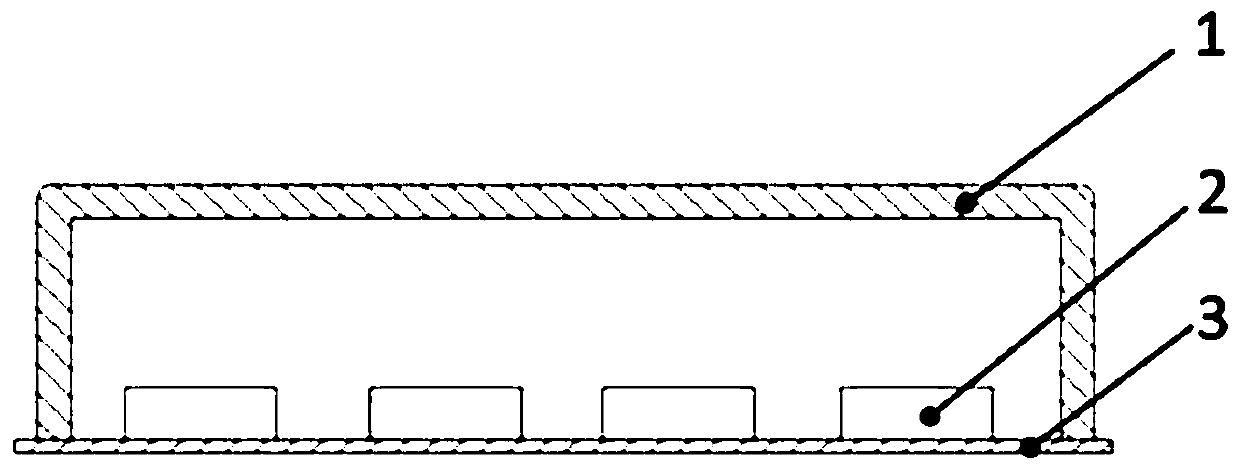

Image

Examples

Embodiment 1

[0028] The present embodiment provides a kind of manufacture method of TC4 titanium alloy tensile rod, specifically comprises the following steps:

[0029] Step 1: First mix polyethylene glycol (PEG), polymethyl methacrylate (PMMA), and stearic acid (SA) in a volume ratio of 70:28:2 to make a binder, and then set the D90 to 0.045mm The TC4 titanium alloy powder and the binder are put into the internal mixer at a volume ratio of 65:35 and filled with argon, mixed at 170°C for 2 hours at a speed of 40r / min and granulated to make a feed;

[0030] Step 2: Use the injection molding machine to inject the above-mentioned feed materials into the mold to make a stretch rod blank. The injection parameters are: the mold temperature is 40°C, and the temperatures in the 1, 2, 3, and 4 areas of the injection molding machine are respectively 160°C, 175°C, 180°C, 185°C, nozzle temperature 190°C, injection pressure 1500bar, holding pressure 1000bar, cooling time 6s;

[0031] Step 3: Immerse t...

Embodiment 2

[0037] Example 2 The same method as in Example 1 was used to prepare TC4 titanium alloy tensile rods, the only difference being that in Step 5 of Example 2, under a vacuum with an air pressure of 30KPa, the thermally degreased billet was cooled to 500°C with furnace cooling and kept 10 minutes

[0038] The mechanical properties of the TC4 titanium alloy tensile rod produced in Example 2 were tested, and the results showed that the density was 97%, the tensile strength was 932Mpa, the yield strength was 870Mpa, and the elongation was 10%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com