Method for plating tin-copper alloys on surfaces of TC4 titanium alloys and TC4 titanium alloy module

A technology of titanium alloy and tin-plated copper, which is applied in the field of steel pipe manufacturing, can solve the problems of poor bonding force of the coating, and achieve the effects of easy operation, excellent wear resistance and stable process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

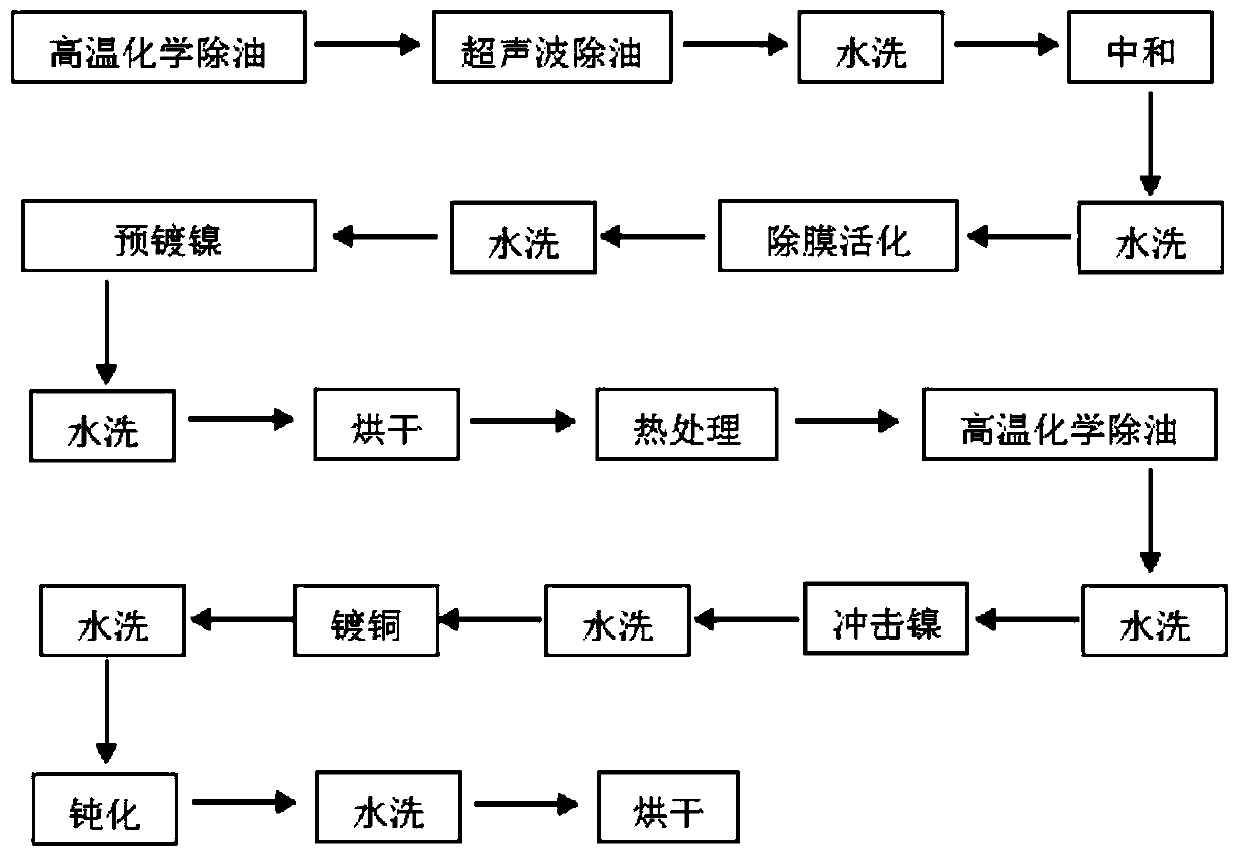

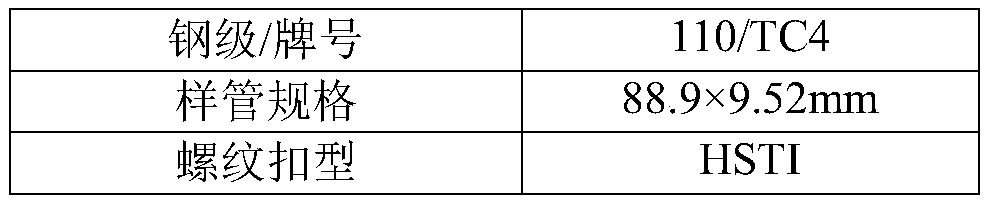

[0041] A method for copper-tin alloy plating of TC4 titanium alloy oil casing collars, the process is as follows figure 1 As shown, the method includes the following steps:

[0042] (1) High-temperature chemical degreasing: immerse the titanium alloy oil casing coupling in an alkaline degreasing solution at a temperature of about 70°C for chemical degreasing, wherein the alkaline solution includes 12g / L sodium hydroxide, 21g / L triphosphate Sodium and 25mL / L BH-7 multifunctional alkaline degreaser, of which BH-7 multifunctional alkaline degreaser is provided by Guangzhou Erqing Research Institute.

[0043] (2) Ultrasonic degreasing: immerse the coupling in an alkaline degreasing liquid with a temperature of about 60°C for ultrasonic degreasing.

[0044] (3) Water washing: wash the degreasing coupling in running water.

[0045] (4) Neutralization: immerse the washed coupling in 5% sulfuric acid solution for 30 seconds to neutralize the residual alkali on the surface.

[0046]...

Embodiment 2

[0078] The difference with Example 1 is: in the pre-nickel treatment step, the current density is 4 amperes / square decimeter, the time is 5 min, and in the titanium alloy pre-nickel solution, the volume content of the titanium alloy pre-nickel agent is 33%.

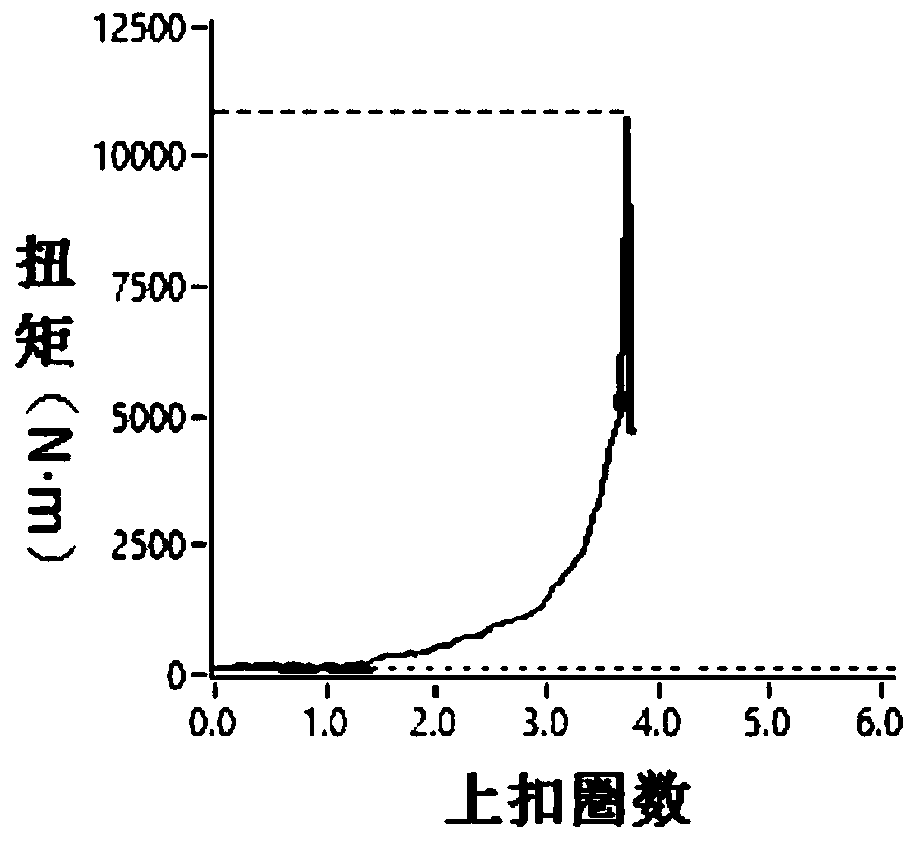

[0079] The test results show that the coating of the oil casing coupling is blistered, and the copper coating on the thread and sealing surface is peeled off after six times of make-up and break-up experiments (make-up torque 11000N×M).

Embodiment 3

[0081] The difference from Example 1 is that steps (9) to (12) are not performed.

[0082] The test results show that the coating of the oil casing coupling is blistered, and the copper coating on the thread and sealing surface has fallen off after three times of make-up and break-up experiments (make-up torque 11000N×M).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com