Superfine glass fiber, preparation method and application thereof, and polyimide film

A technology of ultra-fine glass fiber and polyimide film, applied in the field of polyimide film and glass fiber, can solve problems such as the decline of comprehensive mechanical properties of the film

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

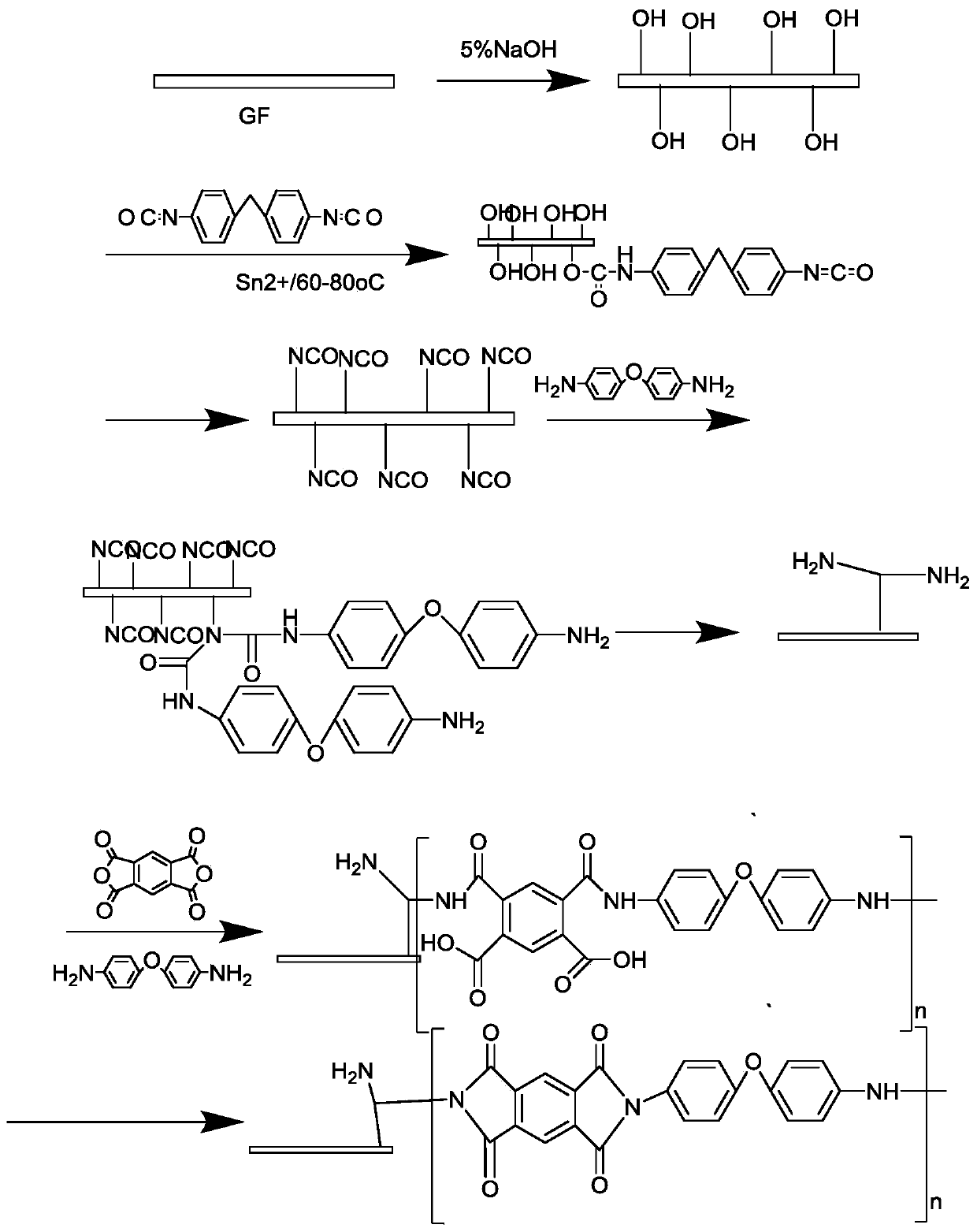

[0043] A preparation method of ultrafine glass fibers, comprising the steps of:

[0044] S1. Take 10 g of glass fibers with an average diameter of 0.8 μm and an average length of 30 μm, soak them in 90 g of 5% sodium hydroxide aqueous solution at room temperature for 4 hours, filter, wash the filter cake with water, and dry it in a vacuum oven at 70 ° C. Disperse in 90g of N,N-dimethylformamide to obtain solution A, raise the temperature to 60°C, add 1g of diphenylmethane diisocyanate and 0.002g of stannous octoate, diphenylmethane diisocyanate and stannous octoate with N, After N-dimethylformamide is dissolved, add it, keep it warm for 4 hours, filter, wash the filter cake with N,N-dimethylformamide, and dry it in a vacuum oven at 70°C to obtain the intermediate material;

[0045] S2. Uniformly disperse 10g of the intermediate material in 90g of N,N-dimethylformamide to obtain solution B. In a nitrogen atmosphere, add 1g of diaminodiphenyl ether to solution B, react at 60°C f...

Embodiment 2

[0047] A preparation method of ultra-fine glass fibers, the diaminodiphenyl ether is replaced by p-phenylenediamine, and the others are the same as in embodiment 1.

Embodiment 3

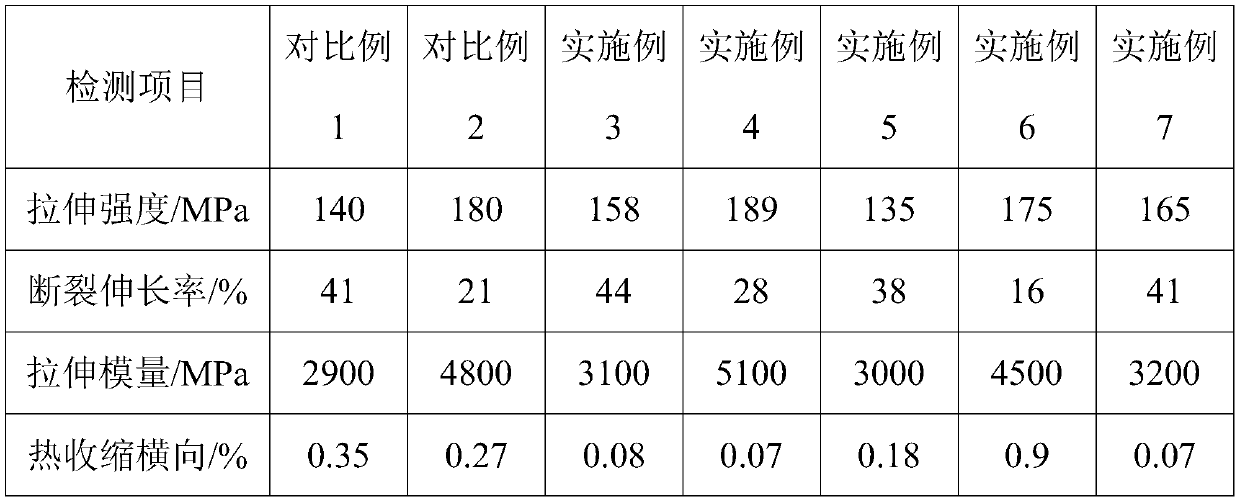

[0049]A low thermal shrinkage polyimide film, the preparation method of which comprises the steps of: dissolving 30g of diaminodiphenyl ether in 300g of N,N-dimethylformamide to obtain a diamine solution; adding 0.2g of diamine to the diamine solution The ultra-fine glass fibers obtained in Example 1 were stirred and dispersed evenly, and then added in portions of pyromellitic dianhydride, and when stirring until the viscosity was 30-130PaS, the addition of pyromellitic dianhydride was stopped to obtain a colloid, and the colloid was placed in a vacuum Degas at room temperature in an oven, then use a film coater to coat a film with a thickness of 300 μm on a glass plate, and then place it in an oven for gradual imidization. The imidization procedure is: keep warm at 80°C for 5 minutes, then heat up to 180°C and keep warm 7min, then raise the temperature to 320°C for 10min, then raise the temperature to 450°C for 5min, tear off the film after cooling to obtain a low-heat-shrinka...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com