Aluminum-plastic composite air bag for pipeline welding and argon filling plugging and preparation method thereof

A technology of aluminum-plastic composite and aluminum-plastic composite film, applied in welding accessories, mechanical equipment, engine sealing, etc., can solve problems such as poor fitting of pipe fittings, water-soluble paper falling off, water-soluble paper burning, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

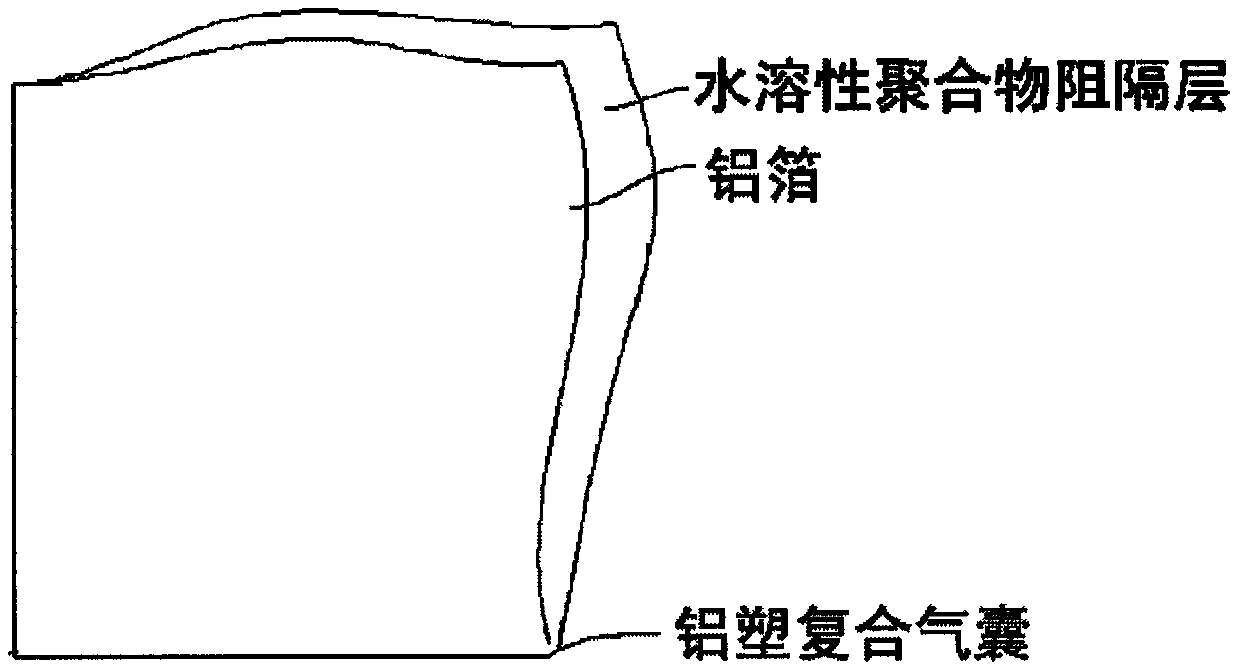

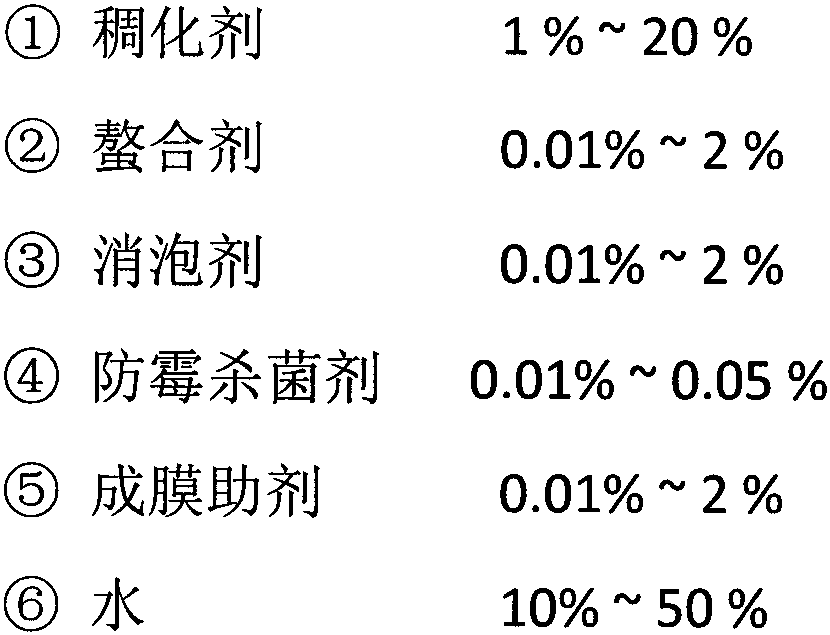

[0018] An aluminum-plastic composite airbag for pipeline welding and argon-filling plugging is prepared from polyvinyl alcohol, defoaming agent, glycerin, chelating agent, film-forming agent, water, aluminum foil and the like. Its preparation method comprises the following steps:

[0019] (1) Dissolve 158.4g of polyvinyl alcohol (grade 1788) in 1,320ml of water at normal temperature and pressure, and add 7.5g of silicone defoamer dropwise. Stir at 1000rpm for 10min, heat at 95°C for 30min to dissolve and keep warm for 2-2.5 hours. A mixed solution containing 10 g of polyacrylamide chelating agent, 0.1 g of propylene glycol butyl ether and 0.1 g of dodecyldimethylbenzyl ammonium chloride was added to the solution, and stirred thoroughly for 20 minutes until completely dissolved and uniformly dispersed. Stop stirring and stand for 2h.

[0020] (2) Cut the aluminum foil paper into circles of corresponding size according to the pipe size. Uniformly coat a layer of the solution ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com