Device and method for removing hexavalent chromium from electroplating wastewater for electrocoagulation-electric flotation

A technology of electroplating wastewater and electric floatation, applied in metallurgical wastewater treatment, chemical instruments and methods, water pollutants, etc., can solve the problems of low removal efficiency, high treatment cost, inconvenient equipment and methods, etc., and reduce electricity consumption , improve the collection efficiency, improve the effect of removal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

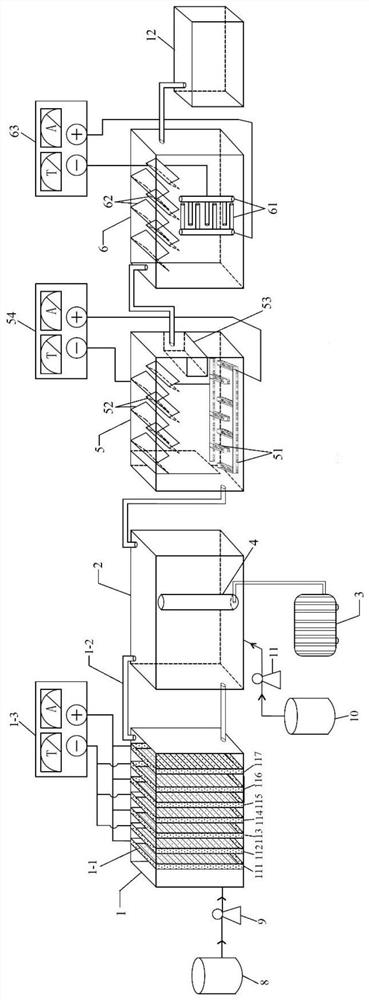

[0033] Such as figure 1 The shown electrocoagulation-electroplating wastewater hexavalent chromium removal device for electroplating wastewater includes an electroflocculation unit 1, a neutralization reaction unit 2, a first electric floating unit 5 and a second electric floating unit 6 arranged and connected in sequence; The flocculation unit 1 is provided with an acid solution pool 8 for maintaining the acidic pH of the electrocoagulation reaction and a first micro-processing pump 9 for pumping the acid solution, and the electrocoagulation unit 1 is provided with a mixed iron-aluminum electrode system 1-1, which It consists of 4 anodes 111, 113, 115, 117 and 3 cathodes 112, 114, 116. Any two anodes in the 4 anodes are iron electrodes, and the other two anodes are aluminum electrodes. For example, 111 and 115 are iron electrodes. Electrodes, while 113 and 117 are aluminum electrodes; also can be 111 and 113 are iron electrodes, while 115 and 117 are aluminum electrodes; also...

Embodiment 2

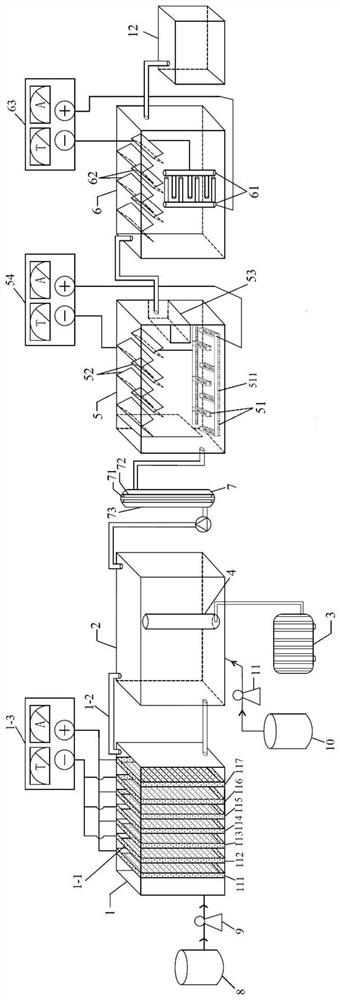

[0052] Such as figure 2 The electroflocculation-electroplating wastewater hexavalent chromium removal device for electroflocculation shown in the example 2 differs from the electroplating wastewater hexavalent chromium removal device for electroflocculation-electric flotation in that:

[0053] 1) The three cathodes 112, 114 and 116 of the mixed iron-aluminum electrode system 1-1 are aluminum electrodes, and are connected to a pulse power supply in a unipolar mode;

[0054] 2) Any two of the four anodes 111, 113, 115, and 117 of the mixed iron-aluminum electrode system 1-1 are iron electrodes, and the other two anodes are aluminum electrodes. Inconsistent;

[0055] 3) A vacuum ultraviolet photocatalytic reaction unit 7 with a peristaltic pump 70 is arranged between the neutralization reaction unit 2 and the first electric floating unit 5, and the vacuum ultraviolet photocatalytic reaction unit is sequentially provided with an ultraviolet lamp 71, a quartz Sleeve 72 and photo...

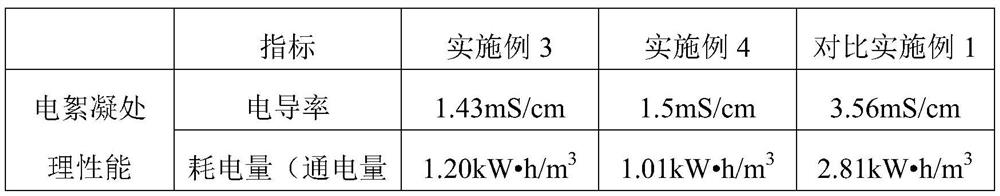

Embodiment 3

[0067] 1) The electroplating waste water is passed into the electroflocculation unit 1, and the sulfuric acid with a volume fraction of 15% in the acid solution pool 8 is pumped into the electroflocculation unit 1 through the first micro-treatment pump 9 to control the pH value in the electroflocculation unit 1 In 5, a cresol acid surfactant with a volume fraction of 0.11% is also added in the acid pool 8, and the power supply device 1-3 is connected, and under the action of an external voltage, the anode of the mixed iron-aluminum electrode system 1-1 111, 113, 115, 117 release cations, and cathodes 112, 114, 116 release OH - , carry out flocculation and sedimentation to the wastewater, and react for 40 minutes;

[0068] 2) The waste water after flocculation and reduction in the electrocoagulation unit 1 is sent into the neutralization reaction unit 2, and is pumped into the lye pool 10 by the second micro-processing pump 11, and is composed of 0.2M NaOH and 0.1M NaOH 2 CO ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com