Preparation method of high-density rare earth tungsten electrode

A rare earth tungsten, dense technology, used in circuits, discharge tubes, electrical components, etc., can solve the problems of complex shapes, inability to prepare large sizes, etc., to achieve a large increase in density, save packaging costs and preparation time, and maximum temperature. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

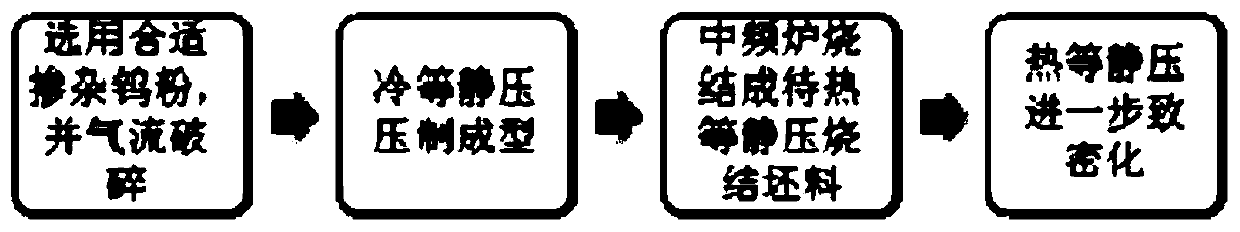

Method used

Image

Examples

Embodiment 1

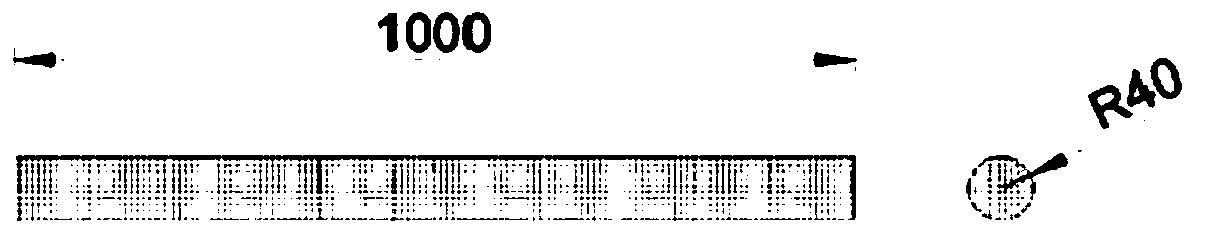

[0037] This example prepares a W-2%La with a relative density of more than 99.5% and a mass content of lanthanum oxide of 2%. 2 o 3 Alloy electrodes, the doping method is liquid-solid doping, the size is Φ40×1000mm, such as figure 2 As shown, the specific steps are as follows:

[0038] (1) The raw material powder W-2% La with a particle size of 2.0 μm 2 o 3 Crushing is carried out with a jet crusher, the rotating speed of the classifying wheel is 60 Hz, and the particle size of the powder after crushing is 1.9 μm.

[0039] (2) Put the crushed powder into a cold isostatic pressing mold for cold isostatic pressing, the pressure of cold isostatic pressing is 210MPa, and the holding time is 20min.

[0040] (3) The blank obtained in step (2) is sintered with a medium-frequency induction heating furnace; the sintering is carried out under a hydrogen atmosphere, and the hydrogen flow rate is 30m 3 / h, the heating rate of the whole temperature section is 70°C / h, and the temperat...

Embodiment 2

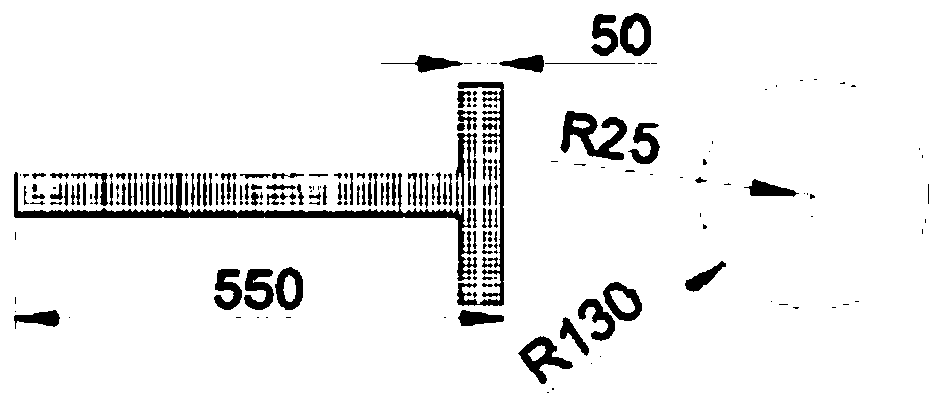

[0044] This example prepares a T-type W-2%Th with a relative density of more than 99.5% and a mass content of thorium oxide of 2%. 2 o 3 Alloy electrode, the doping method is mechanical mixing method, the overall size is Φ260×550mm, such as image 3 As shown, the specific steps are as follows:

[0045] (1) The raw material powder W-2% Th with a particle size of 2.0 μm 2 o 3 Crushing is carried out with a jet crusher, the rotating speed of the classifying wheel is 60 Hz, and the particle size of the powder after crushing is 1.9 μm.

[0046] (2) Put the crushed powder into a cold isostatic pressing mold for cold isostatic pressing, the pressure of cold isostatic pressing is 220MPa, and the holding time is 20min.

[0047] (3) The blank obtained in step (2) is sintered with a medium-frequency induction heating furnace; the sintering is carried out under a hydrogen atmosphere, and the hydrogen flow rate is 30m 3 / h, the heating rate of the whole temperature section is 80°C / h, ...

Embodiment 3

[0051] This example prepares a W-2%La with a relative density of more than 99.5% and a mass content of lanthanum oxide of 2%. 2 o 3 Alloy electrodes, the doping method is liquid-solid doping, the size is Φ40×1000mm, such as figure 2 As shown, the specific steps are as follows:

[0052] (1) The particle size is 2.0μm raw material powder W-2% La 2 o 3 Crushing is carried out with a jet crusher, the rotating speed of the classifying wheel is 60 Hz, and the particle size of the powder after crushing is 1.9 μm.

[0053] (2) Put the crushed powder into a cold isostatic pressing mold for cold isostatic pressing to obtain a billet; the pressure of cold isostatic pressing is 210 MPa, and the holding time is 20 minutes.

[0054] (3) The blank obtained in step (2) is sintered with a medium-frequency induction heating furnace; the sintering is carried out under a hydrogen atmosphere, and the hydrogen flow rate is 30m 3 / hour, the heating rate of the whole temperature section is 70℃ / ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com