A kind of near α-type titanium alloy with high dynamic performance and preparation method thereof

A titanium alloy, high dynamic technology, applied in the field of titanium alloy, can solve the problems of low dynamic performance and instability, and achieve the effect of improving dynamic performance, improving plasticity and toughness, and improving microscopic uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] Step 1, prepare the electrode block:

[0057] AlMo, AlV, TiFe master alloy and sponge titanium and TiO with a particle size of 0.83-12.7mm are used 2 The powder is mixed with a single electrode, and pressed into an electrode block with a large hydraulic press, the pressing pressure is 20-35MPa, and the pressing time is 3-10 seconds; the raw materials are mixed according to the nominal composition ratio, that is, the mass percentage of each element is: Al: 5.0 %, Zr: 1.5%, Mo: 1.0%, V: 1.5%, Fe: 0.05%, O: 0.05%, the balance is Ti, and the sum of the mass percentages of the above components is 100%.

[0058] Step 2, prepare electrodes:

[0059] Clamp the electrode block prepared in step 1 with a clamp, and weld the electrode block into a cylindrical electrode by using a non-tungsten argon shielded plasma box.

[0060] The solder joints are required to be silver gray or light yellow to prevent metallurgical defects such as solder joint oxidation and high-density inclusio...

Embodiment 2

[0072] Step 1, prepare the electrode block:

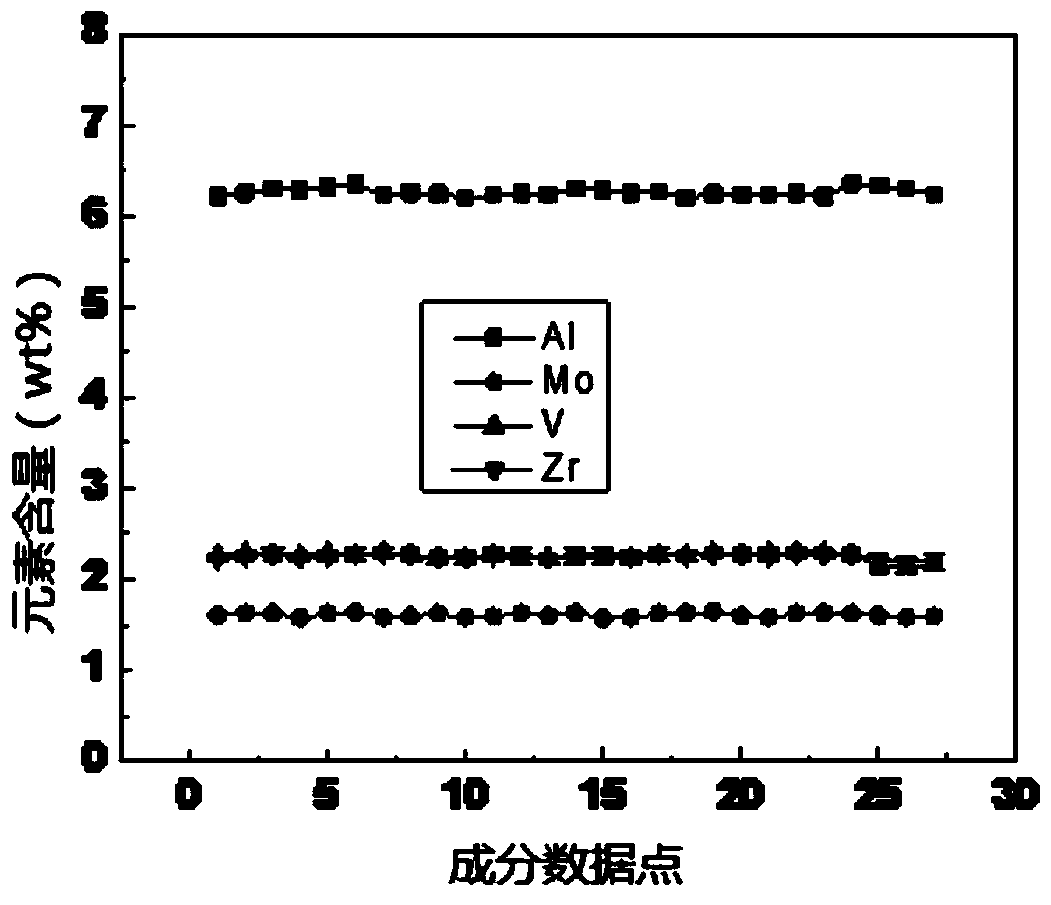

[0073] AlMo, AlV, TiFe master alloy and sponge titanium and TiO with a particle size of 0.83-12.7mm are used 2 The powder is mixed with a single electrode, and pressed into an electrode block with a large hydraulic press. The pressing pressure is 20-35MPa, and the pressing time is 3-10 seconds; the raw materials are mixed according to the nominal composition ratio, that is, the mass percentage of each element is: Al: 6.0 %, Zr: 2.0%, Mo: 1.5%, V: 2.0%, Fe: 0.10%, O: 0.10%, the balance is Ti, and the sum of the mass percentages of the above components is 100%.

[0074] Step 2, prepare electrodes:

[0075] Clamp the electrode block prepared in step 1 with a clamp, and weld the electrode block into a cylindrical electrode by using a non-tungsten argon shielded plasma box.

[0076] The solder joints are required to be silver gray or light yellow to prevent metallurgical defects such as solder joint oxidation and high-density inclusio...

Embodiment 3

[0088] Step 1, prepare the electrode block:

[0089] AlMo, AlV, TiFe master alloy and sponge titanium and TiO with a particle size of 0.83-12.7mm are used 2 The powder is mixed with a single electrode, and pressed into an electrode block with a large hydraulic press. The pressing pressure is 20-35 MPa, and the pressing time is 3-10 seconds; the raw materials are mixed according to the nominal composition ratio, that is, the mass percentage of each element is: Al: 6.8 %, Zr: 2.4%, Mo: 1.9%, V: 2.5%, Fe: 0.30%, O: 0.14%, the balance is Ti, and the sum of the mass percentages of the above components is 100%.

[0090] Step 2, prepare electrodes:

[0091] Clamp the electrode block prepared in step 1 with a clamp, and weld the electrode block into a cylindrical electrode by using a non-tungsten argon shielded plasma box.

[0092] The solder joints are required to be silver gray or light yellow to prevent metallurgical defects such as solder joint oxidation and high-density inclusi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com