Composite fault diagnosis method for rotary machine based on improved deep sparse auto-encoder network

A technology of sparse autoencoder and rotating machinery, which is applied in neural learning methods, biological neural network models, and testing of machine/structural components. Reduce the self-adaptability of diagnostic methods and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0075] The specific implementation of the present invention will be further described in detail below in conjunction with the accompanying drawings, attached tables and examples.

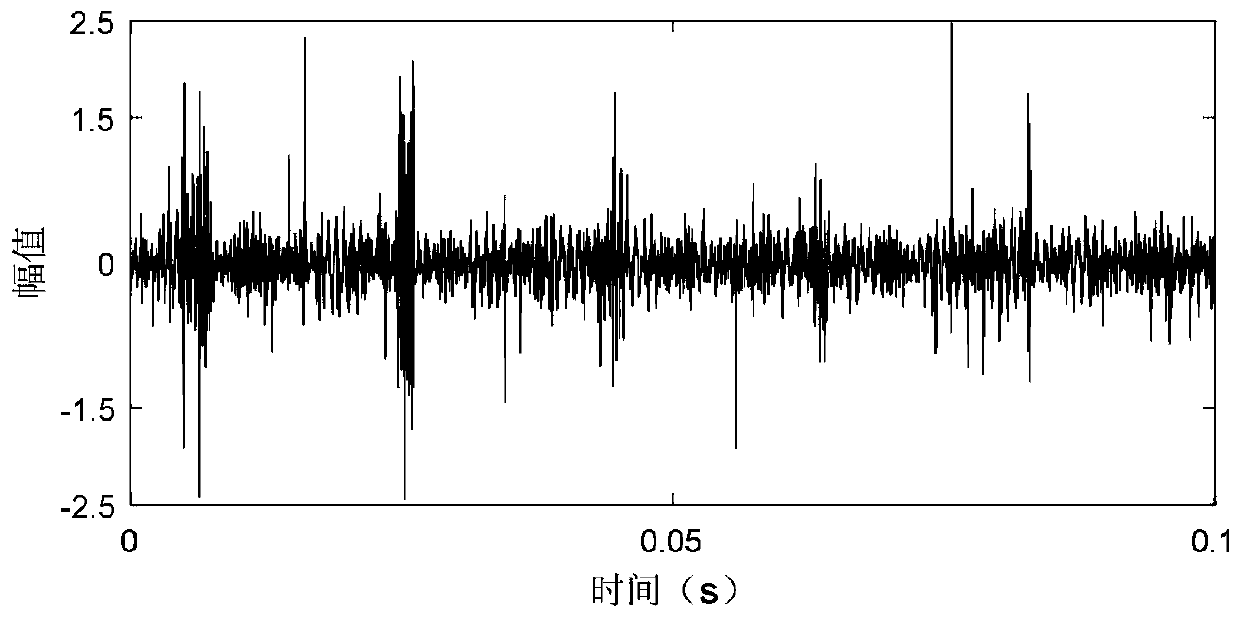

[0076] In order to make up for the deficiencies in the prior art, the present invention is based on the relationship constraint item and the improved deep sparse autoencoder network rotating machinery compound fault diagnosis method, firstly establishes the relationship constraint item that alleviates the correlation between data, and adopts the improved deep sparse autoencoder network The self-encoder network is used to learn the essential characteristics of the training sample data; then the softmax classifier is used to classify and identify the test samples, so as to determine the category of the composite fault condition of the rotating machinery and the severity of the fault, so as to improve the accuracy of the composite fault diagnosis of the rotating machinery , Adaptability, Effectiveness a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com