A kind of preparation method of modified graphene and slurry containing the modified graphene

A graphene modification technology, applied in chemical instruments and methods, anti-corrosion coatings, fibrous fillers, etc., can solve the problems of complex process, high application cost, small production scale, etc., to avoid agglomeration, complete sheet, sheet The effect of fewer layers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

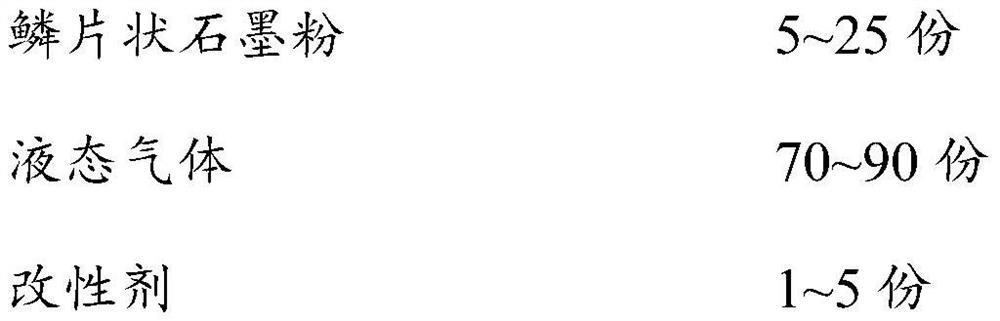

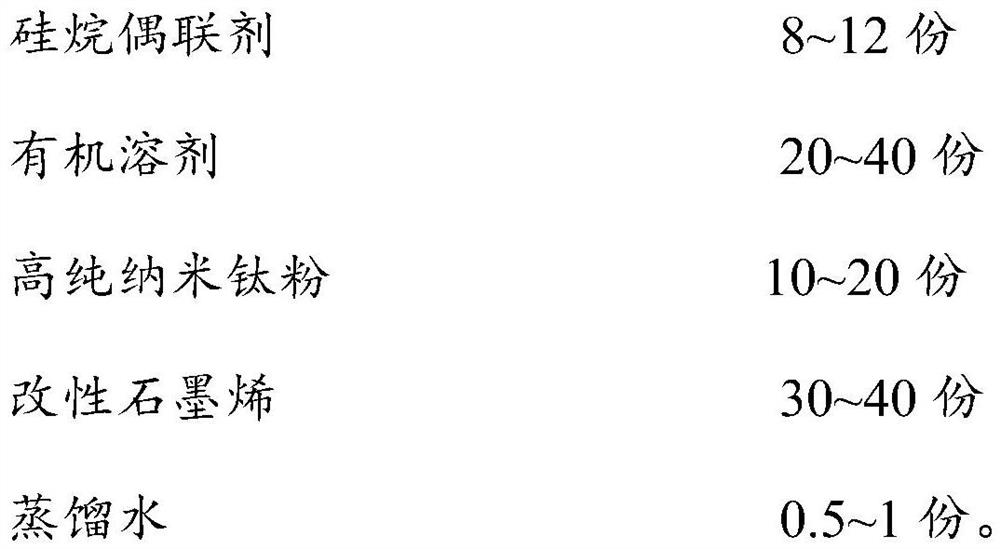

[0037] A kind of preparation method following steps of modified graphene:

[0038] S1 takes silane coupling agent, distilled water and boric acid solution with a substance concentration of 1.5mol / L and places them in a stainless steel high-pressure bottle, seals it well, slowly sucks away the air in the stainless steel high-pressure bottle, and puts it in the stainless steel high-pressure bottle The vacuum degree is 0.09MPA;

[0039] S2 Fill the stainless steel high-pressure bottle described in step S1 with liquid gas, shake it up and let it stand for 24 hours;

[0040] S3 connecting the stainless steel high-pressure bottle described in step S2 to a solid gas preparation machine to prepare solid gas;

[0041] S4 puts the solid gas prepared in step S3 in ultraviolet light and irradiates with ultraviolet light in a washing machine until the solid gas completely disappears to prepare the modified graphene crude product;

[0042] S5 continues to expose the modified graphene crud...

Embodiment 2

[0058] A kind of preparation method following steps of modified graphene:

[0059] S1 takes silane coupling agent, distilled water and boric acid solution with a concentration of 1 mol / L and puts it in a stainless steel high-pressure bottle, seals it well, slowly takes away the air in the stainless steel high-pressure bottle, and vacuums the vacuum in the stainless steel high-pressure bottle The degree is -0.09MPA;

[0060] S2 Fill the stainless steel high-pressure bottle described in step S1 with liquid gas, shake it up and let it stand for 20 hours;

[0061] S3 connecting the stainless steel high-pressure bottle described in step S2 to a solid gas preparation machine to prepare solid gas;

[0062] S4 puts the solid gas prepared in step S3 in ultraviolet light and irradiates with ultraviolet light in a washing machine until the solid gas completely disappears to prepare the modified graphene crude product;

[0063] S5 continues to expose the modified graphene crude product ...

Embodiment 3

[0078] A kind of preparation method following steps of modified graphene:

[0079] S1 takes silane coupling agent, distilled water and boric acid solution with a concentration of 2 mol / L and places it in a stainless steel high-pressure bottle, seals it well, slowly takes away the air in the stainless steel high-pressure bottle, and vacuums the vacuum in the stainless steel high-pressure bottle The degree is 0.1MPA;

[0080] S2 Fill the stainless steel high-pressure bottle described in step S1 with liquid gas, shake it up and let it stand for 28 hours;

[0081] S3 connecting the stainless steel high-pressure bottle described in step S2 to a solid gas preparation machine to prepare solid gas;

[0082] S4 puts the solid gas prepared in step S3 in ultraviolet light and irradiates with ultraviolet light in a washing machine until the solid gas completely disappears to prepare the modified graphene crude product;

[0083] S5 continues to expose the modified graphene crude product ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com