Adhesive, and preparation method and application thereof

An adhesive and initiator technology, applied in the directions of adhesives, adhesive types, starch adhesives, etc., can solve problems such as poor bonding performance, achieve environmentally friendly bonding performance, simple and easy preparation method, and good bonding performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

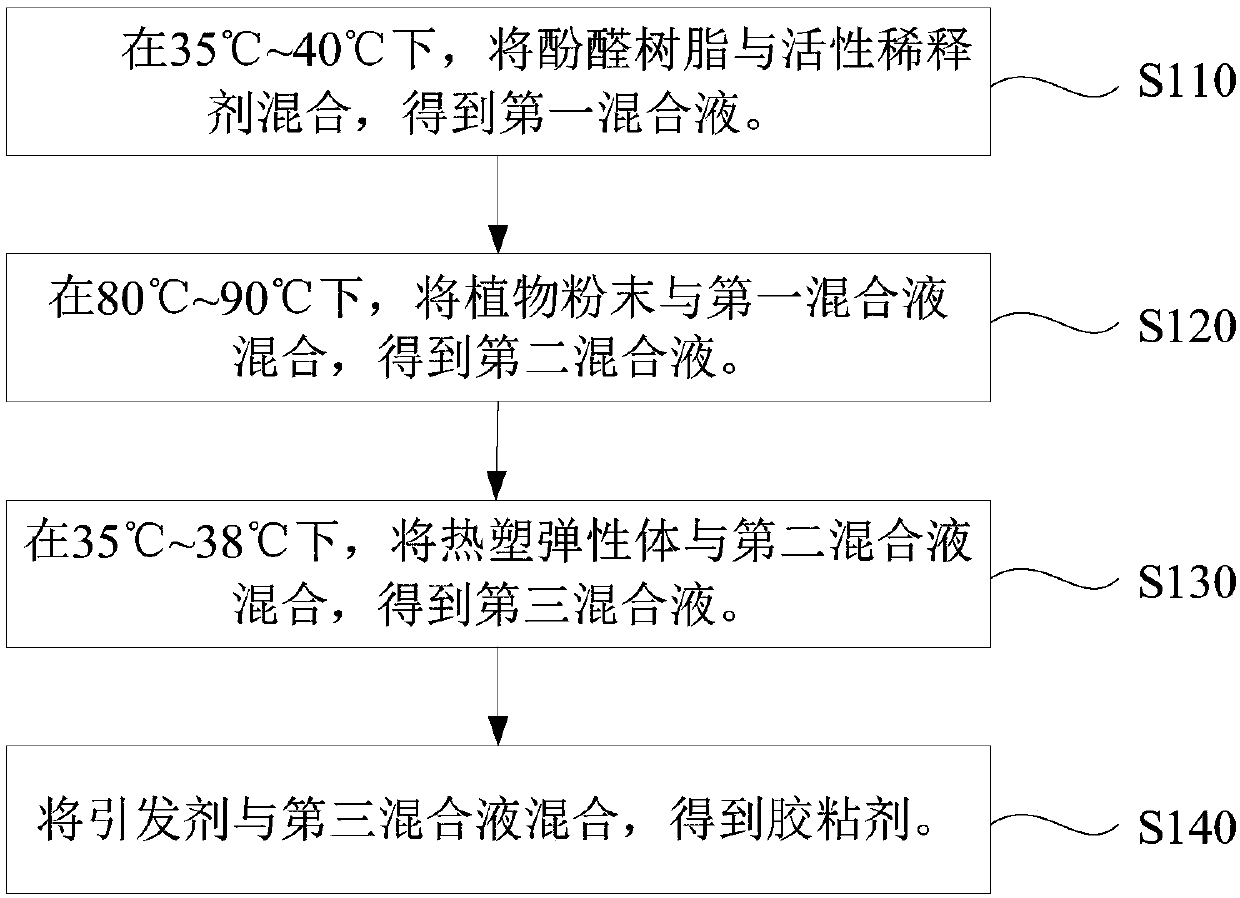

[0043] See figure 1 , The preparation method of an adhesive in an embodiment includes the following steps:

[0044] Step S110: Mix the phenolic resin and the reactive diluent at 35°C to 40°C to obtain a first mixed solution.

[0045] Among them, the step of mixing the phenolic resin and the reactive diluent is specifically: adding the phenolic resin to the reactive diluent and stirring for 60 min to 70 min, and then cooling to room temperature to obtain the first mixed solution, wherein the stirring speed is 60 r / min to 80r / min.

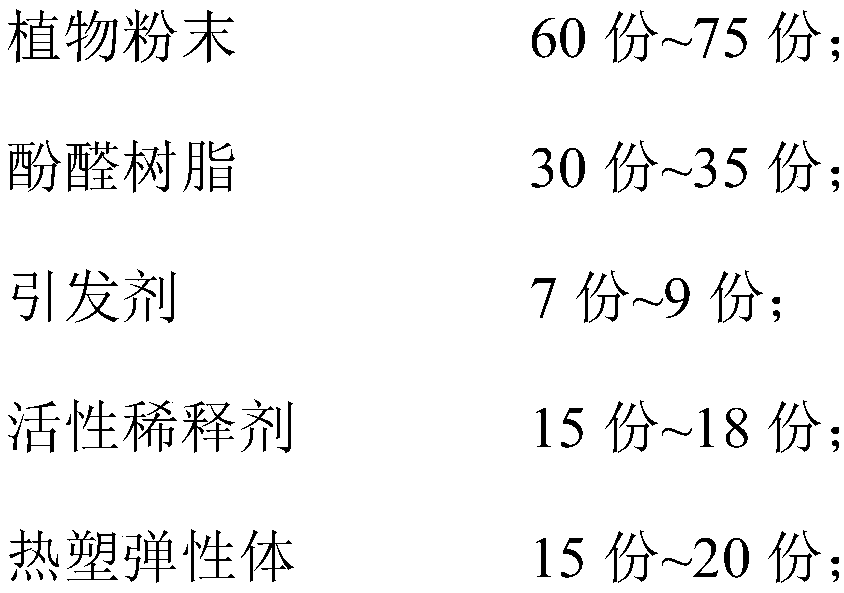

[0046] Among them, the mass parts of the phenol resin is 30 parts to 35 parts. Further, the phenolic resin is selected from at least one of sugar alcohol-modified phenolic resins and resole phenolic resins. Specifically, the phenol resin is a sugar alcohol modified phenol resin.

[0047] Wherein, the mass parts of the active diluent is 15 to 18 parts. Further, the reactive diluent is selected from at least one of butyl glycidyl ether, propylene oxide but...

Embodiment 1

[0069] The preparation steps of the adhesive of this embodiment are as follows:

[0070] 1) At room temperature, 8 parts of phosphoric acid ester, 6 parts of dioctyl sebacate and 15 parts of propylene oxide butyl ether are mixed uniformly in parts by mass to obtain a premixed liquid;

[0071] 2) Add 30 parts of sugar alcohol modified phenolic resin to the premixed liquid at 35° C. and stir for 60 minutes, and then cool to room temperature to obtain the first mixed liquid, wherein the stirring speed is 60 r / min.

[0072] 3) At 80°C, 20 parts of miscanthus flour, 20 parts of tapioca flour, and 20 parts of konjac flour are added to the first mixed solution and stirred for 30 minutes to obtain a second mixed solution, wherein the stirring speed is 50 r / min.

[0073] 4) Add the hydrogenated styrene-butadiene block copolymer to the white oil at 110°C and stir for 30 min, cool to room temperature, and then grind with a grinder to obtain a thermoplastic elastomer with a particle size of 50 μm-...

Embodiment 2

[0077] The preparation steps of the adhesive of this embodiment are as follows:

[0078] 1) At room temperature, 10 parts of phosphoric acid ester, 8 parts of dioctyl sebacate and 16 parts of butyl glycidyl ether are uniformly mixed by mass parts to obtain a premixed liquid;

[0079] 2) At 35° C., add 32 parts of sugar alcohol modified phenolic resin to the premix and stir for 70 min, and then cool to room temperature to obtain the first mixture, wherein the stirring speed is 80 r / min.

[0080] 3) At 90° C., 23 parts of miscanthus flour, 23 parts of tapioca flour and 23 parts of konjac flour are added to the first mixed liquid and stirred for 40 minutes to obtain a second mixed liquid, wherein the stirring speed is 60 r / min.

[0081] 4) Add the hydrogenated styrene-butadiene block copolymer to white oil at 120°C and stir for 30 minutes, cool to room temperature, and then grind with a grinder to obtain a thermoplastic elastomer with a particle size of 50 μm-100 μm. Among them, the stir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com