Cobalt-chromium modified catalyst and its preparation method and application

A technology of catalysts and metal catalysts, applied in chemical instruments and methods, physical/chemical process catalysts, heterogeneous catalyst chemical elements, etc., can solve the problems of limited catalyst improvement and weak conversion, and achieve the promotion of redox sites and Effect of acidic sites, increased adsorption rate, increased capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1-10

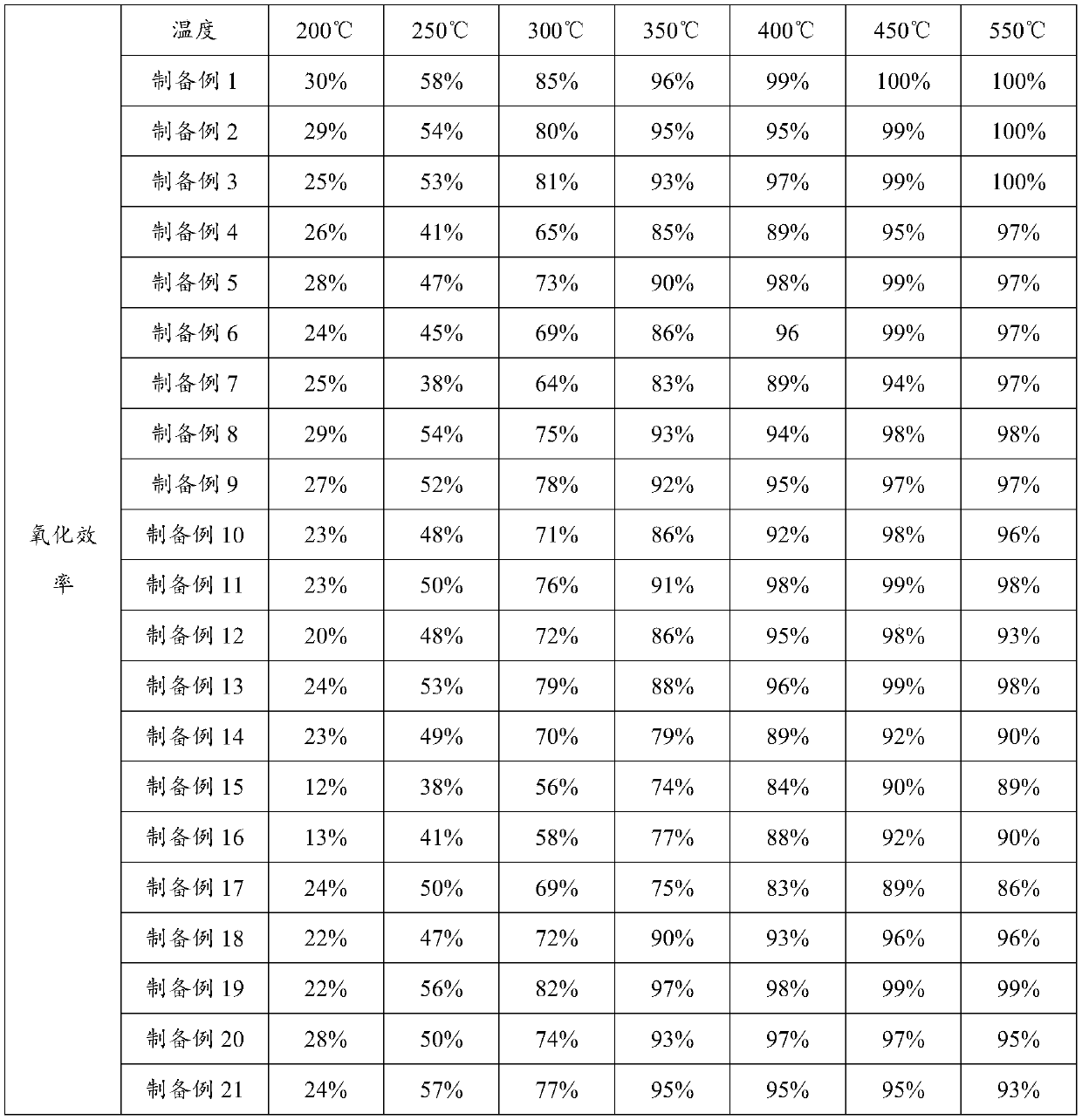

[0044] Preparation Example 1-10 Preparation of cobalt-chromium modified catalyst

[0045] Unless otherwise specified, the metal elements in the catalyst come from the following raw materials: chromium nitrate, tungsten phosphate, vanadyl acetylacetonate, titanium dioxide, molybdenum trioxide, cobalt nitrate, cerium nitrate, manganese nitrate; the content of the raw materials is shown in Table 1 below .

[0046] According to the elemental composition in Table 1, after preliminary mixing of the raw materials, put them into a ball mill tank for ball milling, ball milling for 70min, with a rotation speed of 55 rpm, then dry the ball milled mixture (110°C, 6h) and roast in an air atmosphere. Carried out in a furnace, including heating up to 100°C at a rate of 8°C / min and keeping for 10 minutes; then heating up to 200°C at a rate of 8°C / min and keeping for 12 minutes; then heating up to 500°C at a rate of 8°C / min Leave on for 3 hours. After the calcination, the catalyst is cooled...

preparation example 20

[0050] Preparation Example 20 Preparation of cobalt-chromium modified catalyst

[0051] Raw material consumption and composition are the same as Preparation Example 1, adopt the following preparation method:

[0052] After preliminarily mixing the raw materials, put them into a ball mill tank for ball milling, ball milling for 70 minutes at a speed of 55 rpm, then dry the ball milled mixture (110°C, 6h) and roast in an air atmosphere. The roasting is carried out in a muffle furnace. Including heating at a rate of 8°C / min to 500°C for 3 hours. After the calcination is completed, it is cooled with the furnace to obtain a cobalt-chromium modified catalyst in the form of powder with a particle size of 40-80 mesh.

preparation example 21

[0053] Preparation of Preparation Example 21 Cobalt-Chromium Modified Catalyst

[0054] Raw material consumption and composition are the same as Preparation Example 1, adopt the following preparation method:

[0055] Take the raw materials for preliminary mixing, and then put them into a ball mill tank for ball milling, ball milling for 70 minutes, and the speed is 55 rpm; the ball mill mixture is taken out and dried at 110°C for 6 hours, and directly roasted in the air atmosphere at 500°C for 3 hours; finally, it is cooled in the furnace to obtain cobalt - The chromium modified catalyst is a powder with a particle size of 20-90 mesh.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com