High-strength pressure-resistant polyethylene composite pipe and preparation method thereof

A polyethylene composite pipe and polyethylene pipe technology, applied in the field of composite pipes, can solve the problems that the sheet cannot be flattened and pressed on the core pipe, the conveying pipeline is easily damaged, and it is inconvenient to grind and extrude the sheet, so as to achieve high toughness and water absorption. Small size, good bonding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

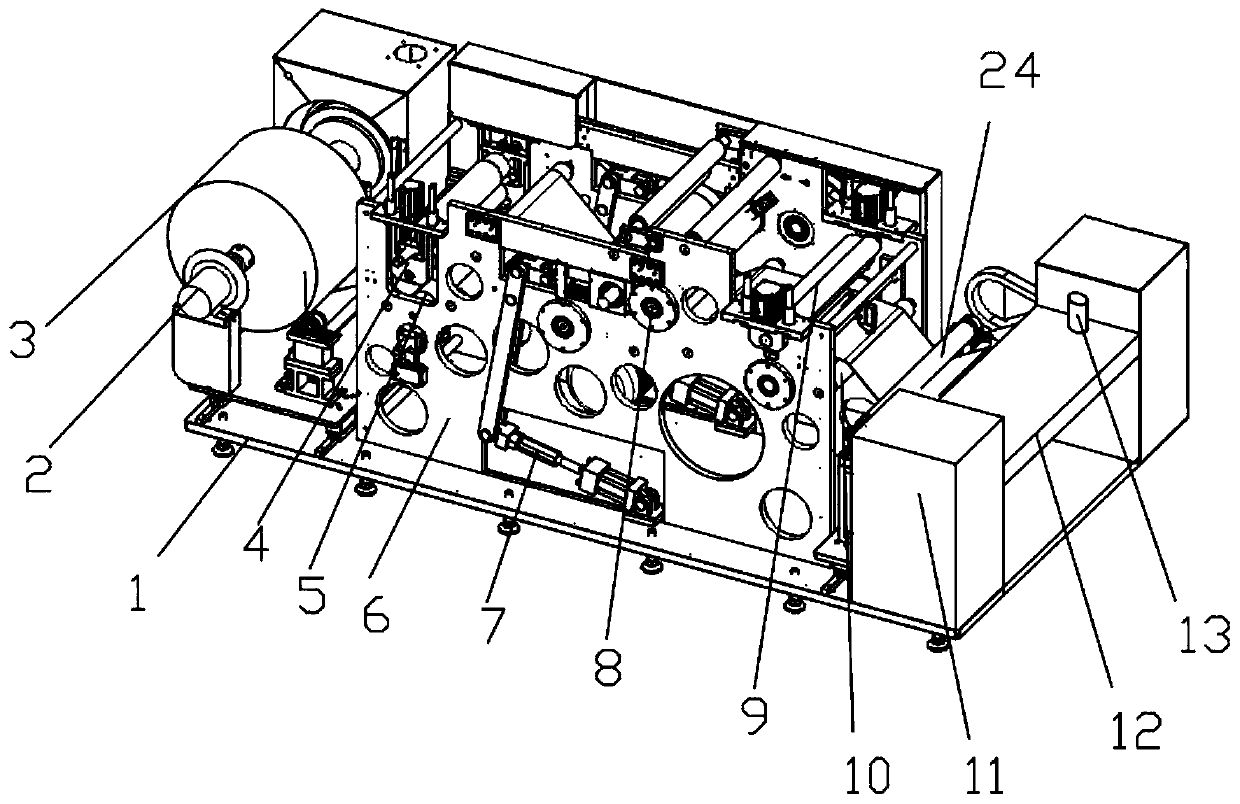

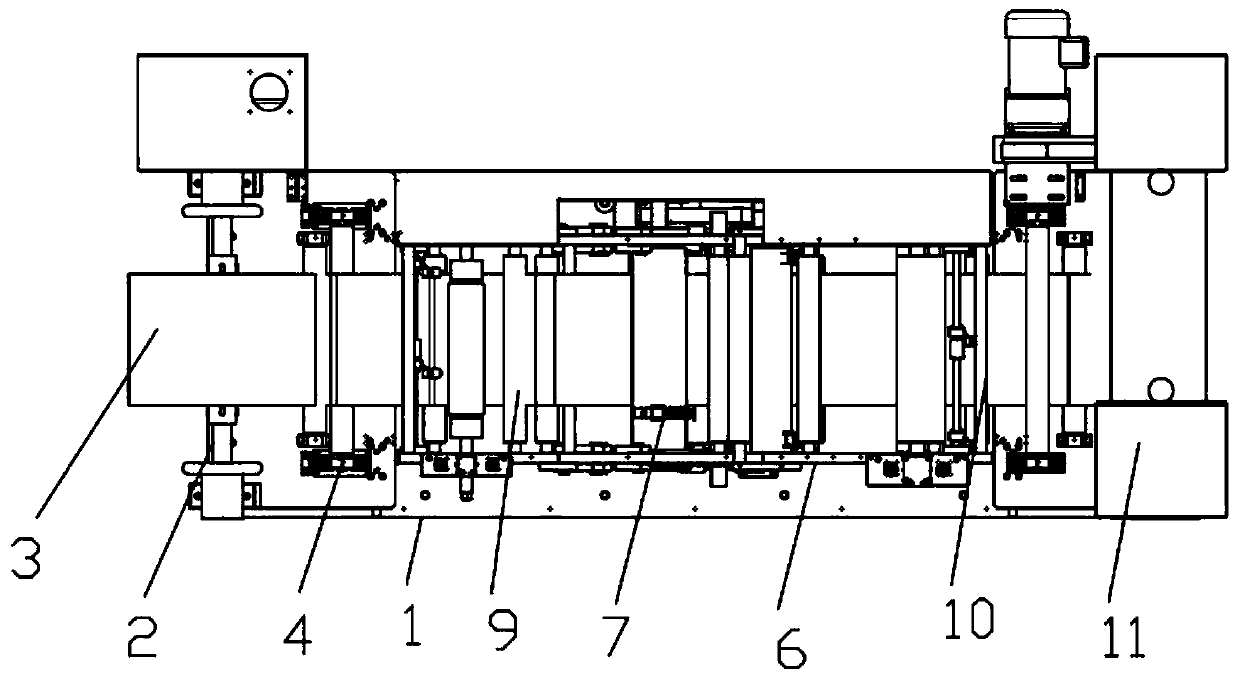

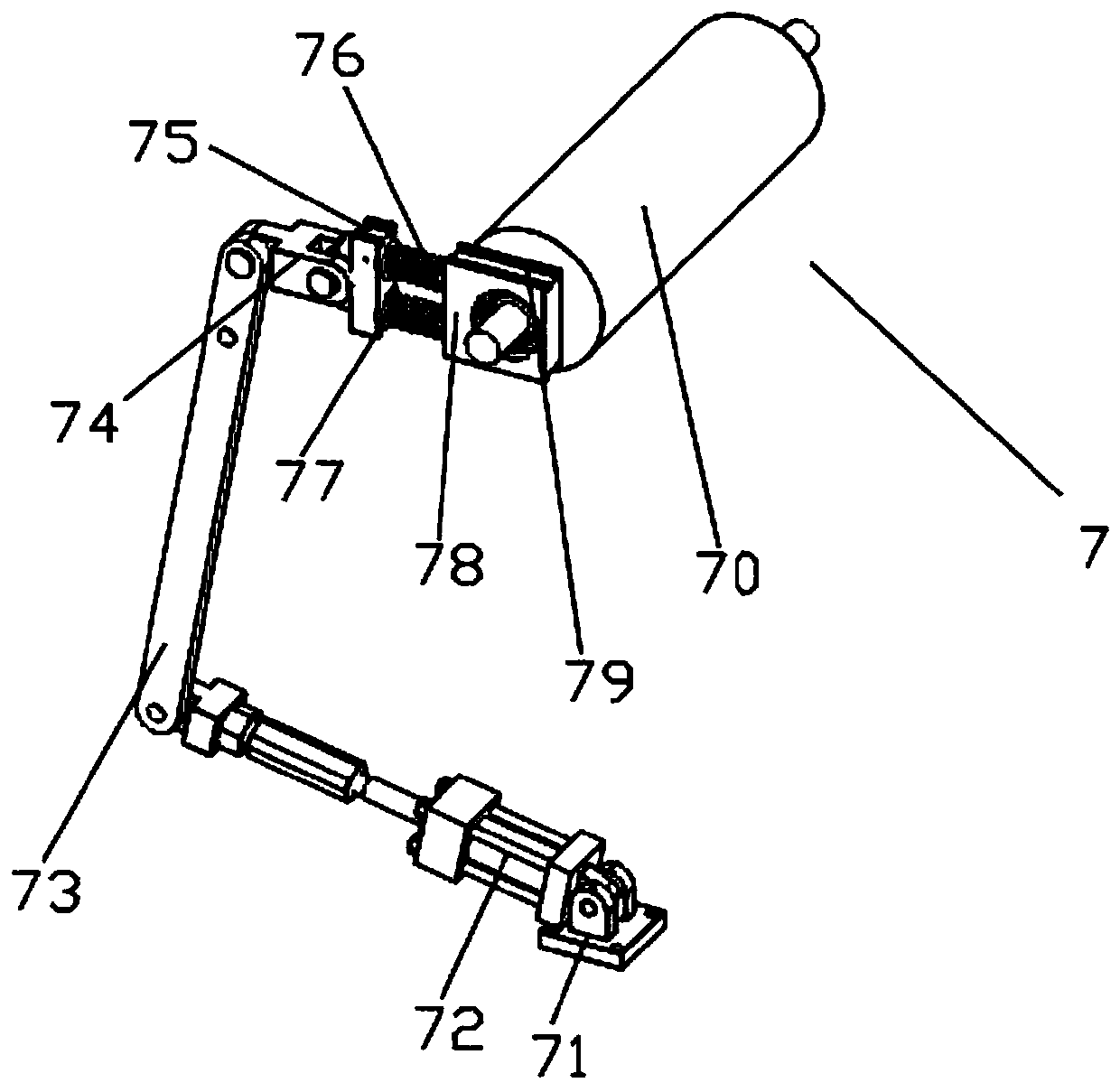

Image

Examples

preparation example Construction

[0045] A method for preparing a high-strength pressure-resistant polyethylene composite pipe, comprising the following steps:

[0046] (1) In parts by weight, weigh polyethylene 190, chlorinated polyethylene 40, epoxy resin 85, dibutyltin dilaurate 9, calcium stearate 10, polyethylene wax 11, jade powder 9, barium laurate 8. Hydrocarbyl phosphoric acid 10, fluorine resin 9, glycidyl methacrylate 7, silane coupling agent 15, polyethylene terephthalate 16, phosphite antioxidant 15, nano zirconium dioxide 13 , Auxiliary masterbatch 11;

[0047] (2) After mixing the raw materials other than epoxy resin, add them to a high-speed kneader and knead for 10 minutes, the kneading temperature is 180°C, then send the raw materials into the cold mixer and stir until the temperature is 40°C before cutting;

[0048] (3) Put the raw materials obtained in step (2) into the hoppers of the core pipe polyethylene pipe screw extruder and the outer layer polyethylene pipe extruder in proportion, a...

Embodiment 2

[0058] A high-strength pressure-resistant polyethylene composite pipe, comprising a core pipe, a sheet skeleton reinforcement layer and an outer layer; a sheet skeleton reinforcement layer is arranged between the core pipe and the outer layer;

[0059] The material of the core tube and the outer layer is the same, and it is prepared from the following raw materials in parts by weight: polyethylene 180, chlorinated polyethylene 35, epoxy resin 75, dibutyltin dilaurate 8, calcium stearate 7, poly Ethylene wax 9, jade powder 7, barium laurate 6, hydrocarbyl phosphoric acid 8, fluorine resin 5, glycidyl methacrylate 6, silane coupling agent 10, polyethylene terephthalate 11, phosphite Antioxidant 13, Nano Zirconium Dioxide 11, Auxiliary Masterbatch 9;

[0060] The additive masterbatch is made of the following raw materials in parts by weight: polyamide 30, butyl naphthenate 12-14, dimethyl fumarate 7, sodium benzoate 6, ultrafine carbon black 9, tribasic o- Lead phthalate 5, nano...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adhesivity | aaaaa | aaaaa |

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com