Preparation method of polyester-nylon parallel composite elastic fiber

A composite elastic fiber and polyester-nylon technology, which is applied in the field of preparation of polyester-nylon side-by-side composite elastic fibers, can solve the problems of poor compatibility between polyester and nylon, and easy fiber opening of side-by-side composite fibers, so as to hinder heat conduction, promote char formation, Avoid the effect of fiber opening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

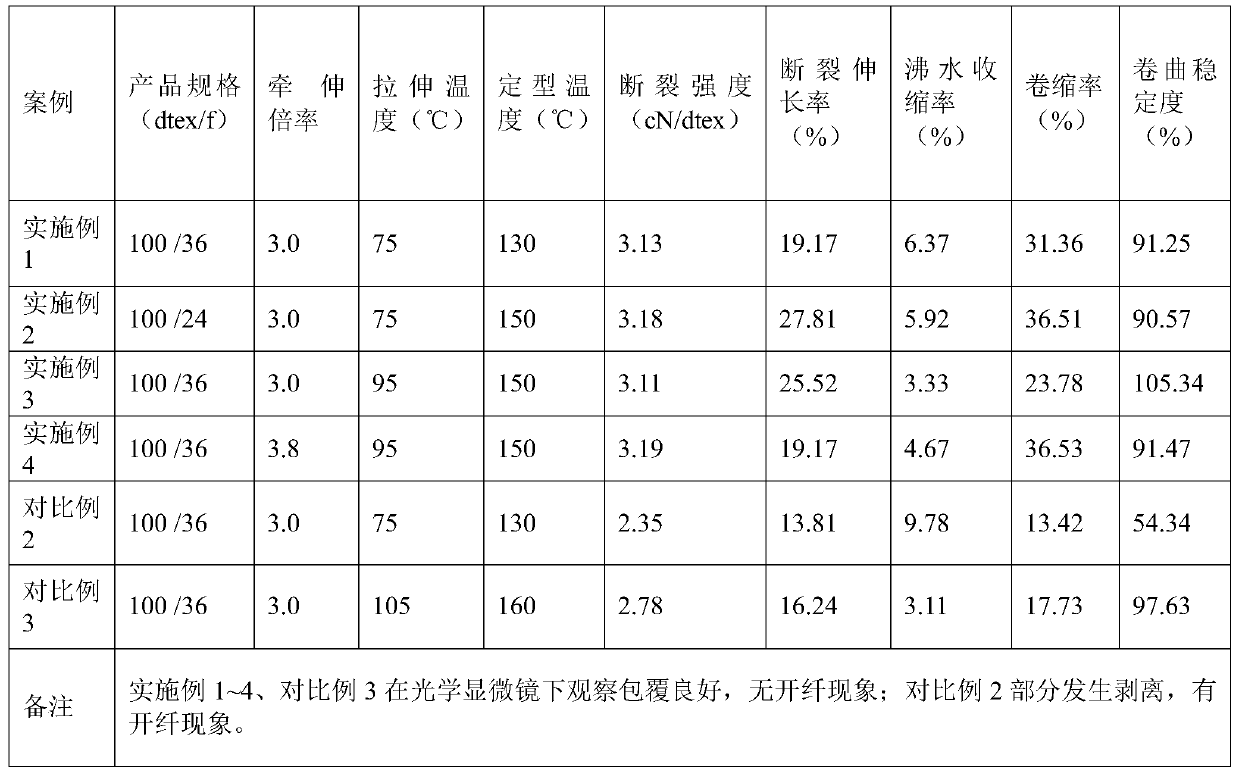

[0033] General embodiment A kind of preparation method of polyamide juxtaposed composite elastic fiber (fiber specification is 100dtex / 36~48f), comprises the following steps:

[0034] 1) According to the mass ratio of 25:75-45:55, PET chips and nylon 6 chips are dried separately and then melted by a screw extruder (260-285° C.), to obtain PET spinning melt and nylon 6 spinning melt.

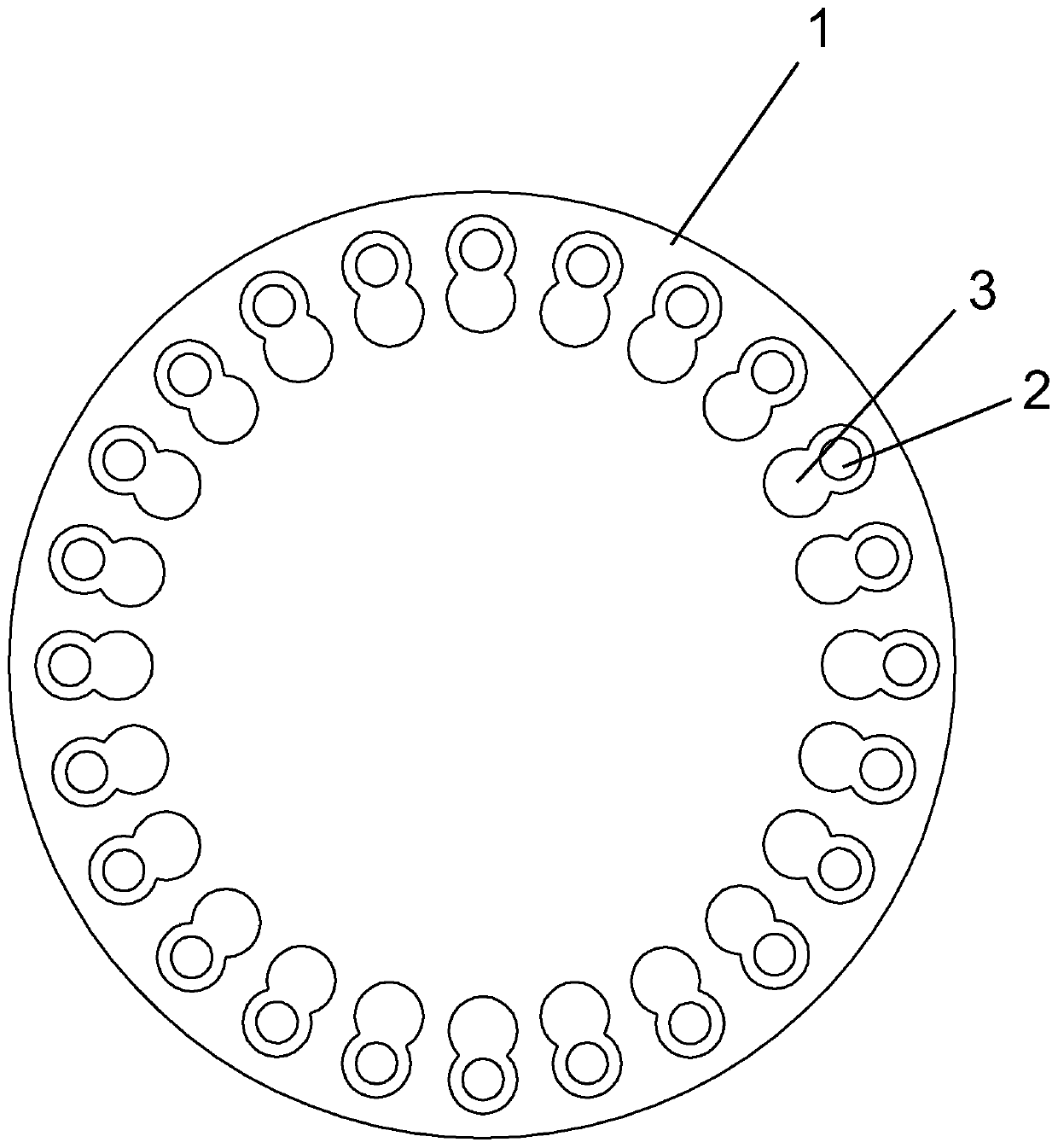

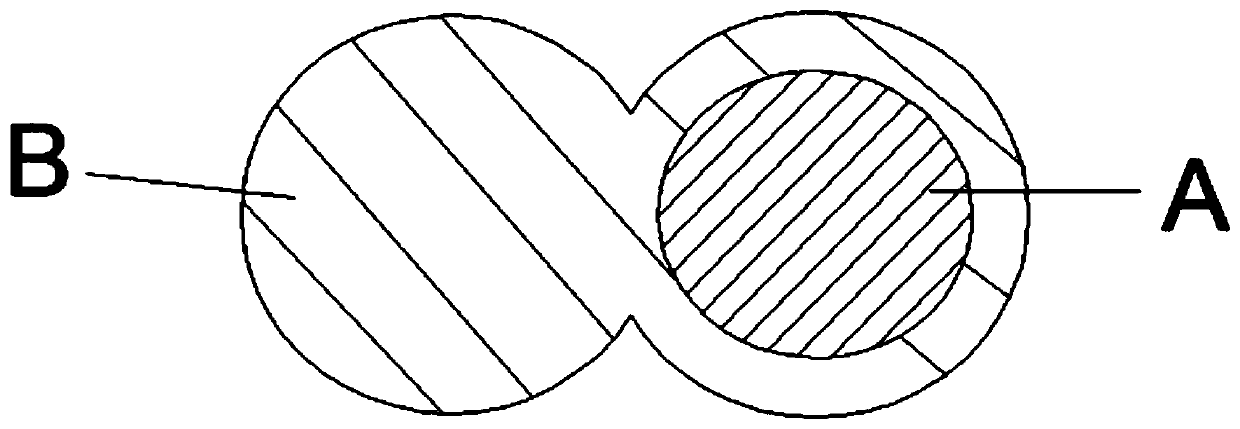

[0035] 2) The two spinning melts enter the two-component composite spinning assembly through their corresponding pipes for spinning (the temperature of the spinning box is 260-285°C), and the two spinning melts are spun from the sheath-core composite spinning The sheets are extruded to form filaments.

[0036] 3) After the filaments are cooled, oiled, stretched and shaped (the temperature of the first hot roller is 75-95°C, the temperature of the second hot roller is 130-150°C; the draw ratio is 3.0-4.0) and winding, the obtained Polyester-nylon side-by-side composite elastic fiber; two componen...

Embodiment 1

[0043] Raw material composition: PET chip (intrinsic viscosity 0.65±0.2dL / g, melting point 260~265℃)

[0044] PA6 chips (relative viscosity 2.47±0.2, melting point 215~225℃)

[0045] Dry polyester (PET) slices and nylon 6 (PA6) slices separately. The drying temperature of the polyester chips is 130°C, and the drying time is 20 hours. After drying, the water content of the polyester chips is less than 50ppm. The drying temperature of the nylon 6 chips is 95°C, the drying time is 24 hours, and the water content of the nylon 6 chips after drying treatment is less than 100ppm.

[0046] The dried polyester chips and nylon chips are sent to the twin-screw extruder according to the set compounding ratio (40:60) to be melted and extruded. The melt pipe enters the composite spinning group by the spinneret (such as figure 1 (shown) is sprayed out, then cooled by side blowing, oiled, coiled, the first hot roll, the second hot roll, and FDY coiled to form a finished product.

[0047] ...

Embodiment 2

[0050] The setting and working principle of this embodiment are the same as that of Embodiment 1, the difference is that:

[0051] Among them, PET is used as component A, and the temperature of each zone of the screw is 260-285°C; PA6 is used as component B, the temperature of each zone of the screw is 260-270°C, the temperature of the spinning box is 275°C, and the wind speed of side blowing is 0.7m / s; The wire speed is 1200m / min, the temperature is 75°C; the temperature of the second hot roller is 150°C, and the draw ratio is 3.0.

[0052] The specification of the self-crimping composite filament prepared by the above process is 100dtex / 24f.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com