A rare earth-based high-entropy amorphous alloy with high magnetocaloric effect and its preparation method

An amorphous alloy, rare earth-based technology, applied in the field of rare earth-based high-entropy amorphous alloys with large half-peak width and high magnetocaloric effect and its preparation, can solve the problem of increasing time and energy costs, only relative magnetic refrigeration capacity, and magnetic phase The problem of narrow variable temperature range can achieve the effects of high energy utilization efficiency, improved magnetic refrigeration capacity, and large amorphous formation capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

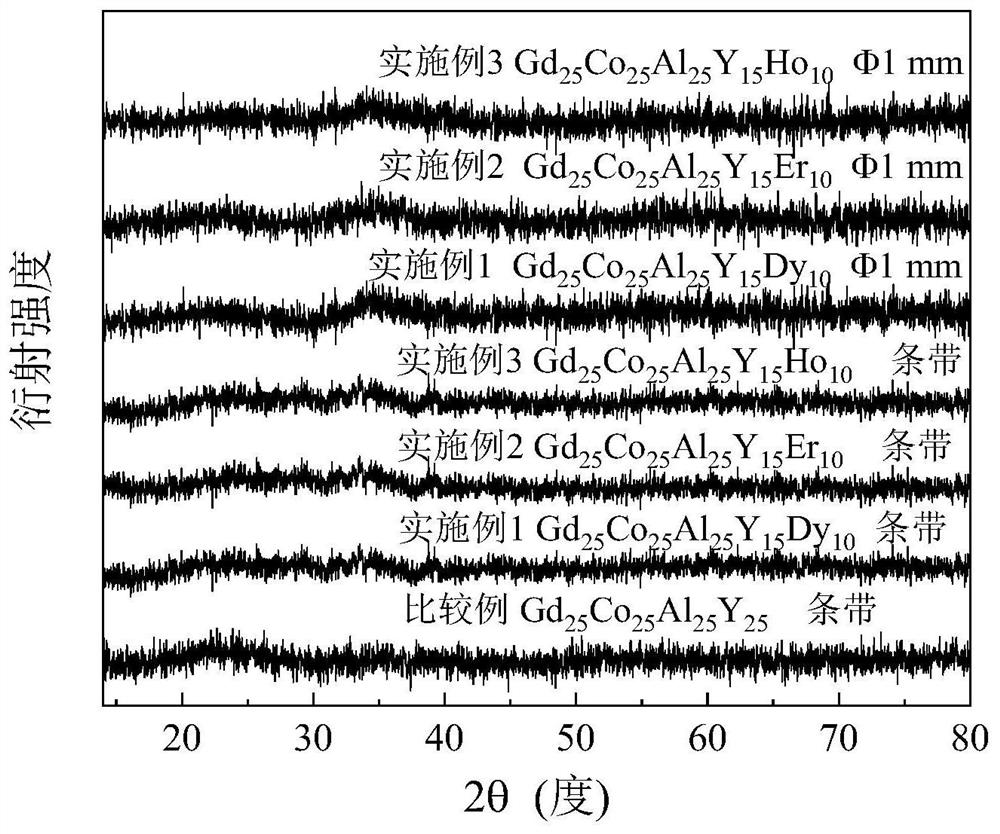

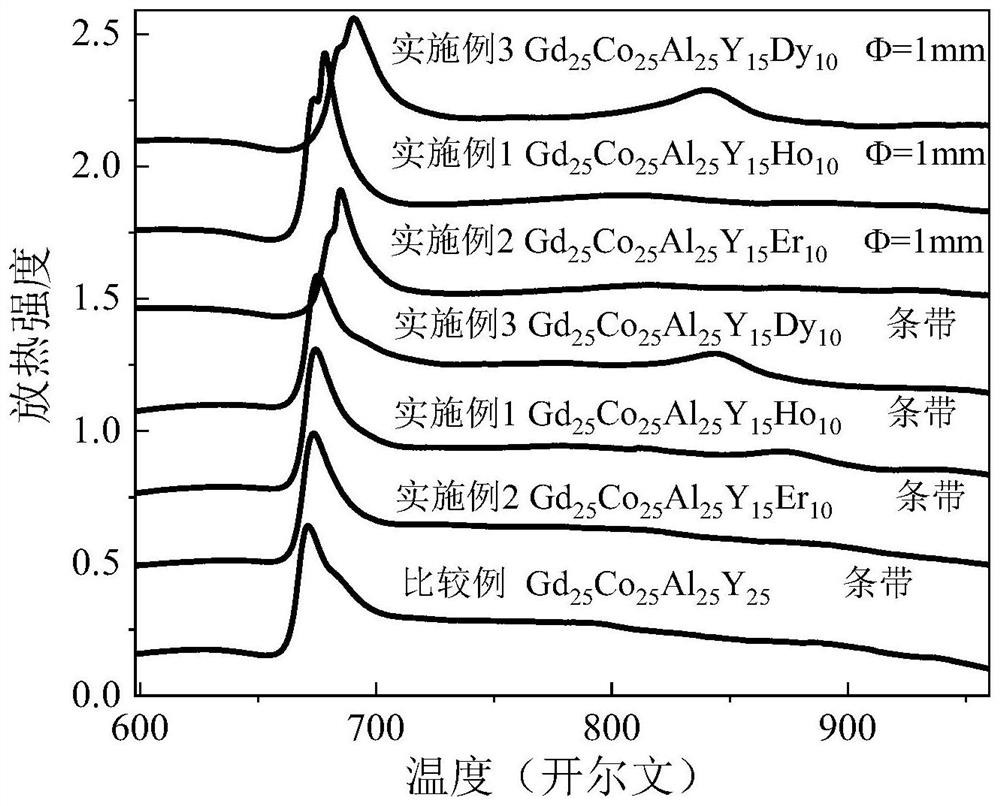

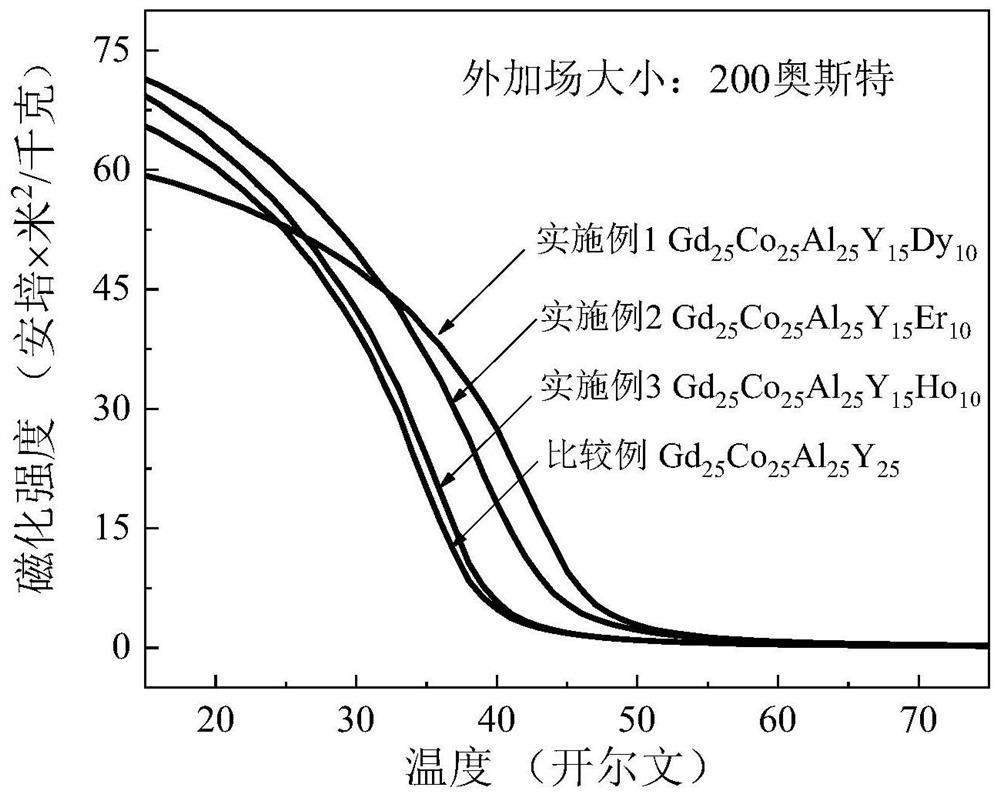

[0035] In this embodiment, the molecular formula of the rare earth-based high-entropy amorphous alloy material is Gd 25 co 25 al 25 Y 15 Dy 10 .

[0036] The preparation method of the rare earth-based high-entropy amorphous alloy material is as follows:

[0037] (1) The raw materials of gadolinium, cobalt, aluminum, yttrium and dysprosium with a purity greater than 99% according to the molecular formula Gd 25 co 25 al 25 Y 15 Dy 10 The atomic percentage of the ingredients shown is for weighing and batching;

[0038] (2) Put the raw material prepared in step 1 into the water-cooled copper crucible of the electric arc melting furnace, close the door of the melting furnace chamber, and the vacuum degree in the chamber is 5×10 -3 Under the condition of Pa, fill in inert gas for protective smelting. After the raw material is melted by the arc, the arc is turned off after continuous smelting for 3 minutes, and the master alloy is cooled with the crucible. After the master ...

Embodiment 2

[0044] In this embodiment, the molecular formula of the rare earth-based high-entropy amorphous alloy material is Gd 25 co 25 al 25 Y 15 Er 10 .

[0045] The preparation method of the rare earth-based high-entropy amorphous alloy material is as follows:

[0046] (1) Gadolinium, cobalt, aluminum, yttrium, and erbium raw materials with a purity greater than 99% are prepared according to the molecular formula Gd 25 co 25 al 25 Y 15 Er 10 The atomic percentages of the ingredients shown are used for batching;

[0047] (2) Put the raw material prepared in step 1 into the water-cooled copper crucible of the electric arc melting furnace, close the door of the melting furnace chamber, and the vacuum degree in the chamber is 4×10 -3 Under the condition of Pa, fill in inert gas for protective melting. After the raw materials are melted by the arc, the arc is turned off after continuous melting for 10 minutes, and the master alloy is cooled with the crucible. After the master al...

Embodiment 3

[0053] In this embodiment, the molecular formula of the rare earth-based high-entropy amorphous alloy material is Gd 25 co 25 al 25 Y 15 Ho 10 .

[0054] The preparation method of the rare earth-based high-entropy amorphous alloy material is as follows:

[0055] (1) Gadolinium, cobalt, aluminum, yttrium, and holmium raw materials with a purity greater than 99% are prepared according to the molecular formula Gd 25 co 25 al 25 Y 15 Ho 10 The atomic percentages of the ingredients shown are used for batching;

[0056] (2) Put the raw material prepared in step 1 into the water-cooled copper crucible of the electric arc melting furnace, close the door of the melting furnace chamber, and the vacuum degree in the chamber is 5×10 -3 Under the condition of Pa, fill in inert gas for protective melting. After the raw materials are melted by the arc, the arc is turned off after continuous melting for 5 minutes, and the master alloy is cooled with the crucible. After the master al...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com