Manufacturing method of control cable used in containment vessel of third-generation nuclear power station

A nuclear power plant containment and control cable technology, applied in the field of nuclear power, can solve the problem that the cable performance cannot meet the requirements of the third-generation nuclear power plant, etc., and achieve the effects of high flame retardancy, excellent electrical performance, and high electrical insulation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Embodiment 1 The manufacturing method of the control cable used in the containment of the third generation nuclear power plant

[0043] First of all, the material selection step of S1 is specifically to select the copper wire blank for electrical use as the conductor, and the polyimide film tape must be selected to withstand high temperature above 200 °C. High polymer material, the inner insulation is made of radiation-resistant cross-linked polyethylene with high electrical performance, the outer insulation is made of radiation-resistant, halogen-free, low-smoke, flame-retardant cross-linked polyolefin, and the sheath is made of radiation-resistant, halogen-free, low-smoke, flame-retardant cross-linked polyolefin .

[0044] S2 wire drawing step specifically refers to a pressure processing method in which the electrical copper wire billet passes through multiple die holes on the wire drawing equipment and undergoes plastic deformation under a certain tension, so that th...

Embodiment 2

[0057] Embodiment 2 The manufacturing method of the control cable used in the containment of the third generation nuclear power plant

[0058] First of all, carry out the S1 material selection step, specifically the conductor selection of copper wire blank for electrical use, the polyimide film belt must be selected with a high temperature resistance above 200 ℃, and the insulation and sheath materials must be selected after long-term heat resistance evaluation for its thermal life More than 60 years of polymer materials, the inner insulation is made of high electrical performance radiation-resistant cross-linked ethylene propylene, the outer insulation is made of radiation-resistant, halogen-free, low-smoke, flame-retardant cross-linked ethylene-propylene, and the sheath is made of radiation-resistant, halogen-free, low-smoke, flame-retardant cross-linked ethylene propylene.

[0059] S2 wire drawing step specifically refers to a pressure processing method in which the electri...

Embodiment 3

[0072]Example 3 Performance Testing Experiment of Control Cables Used in the Containment of the Third Generation Nuclear Power Plant

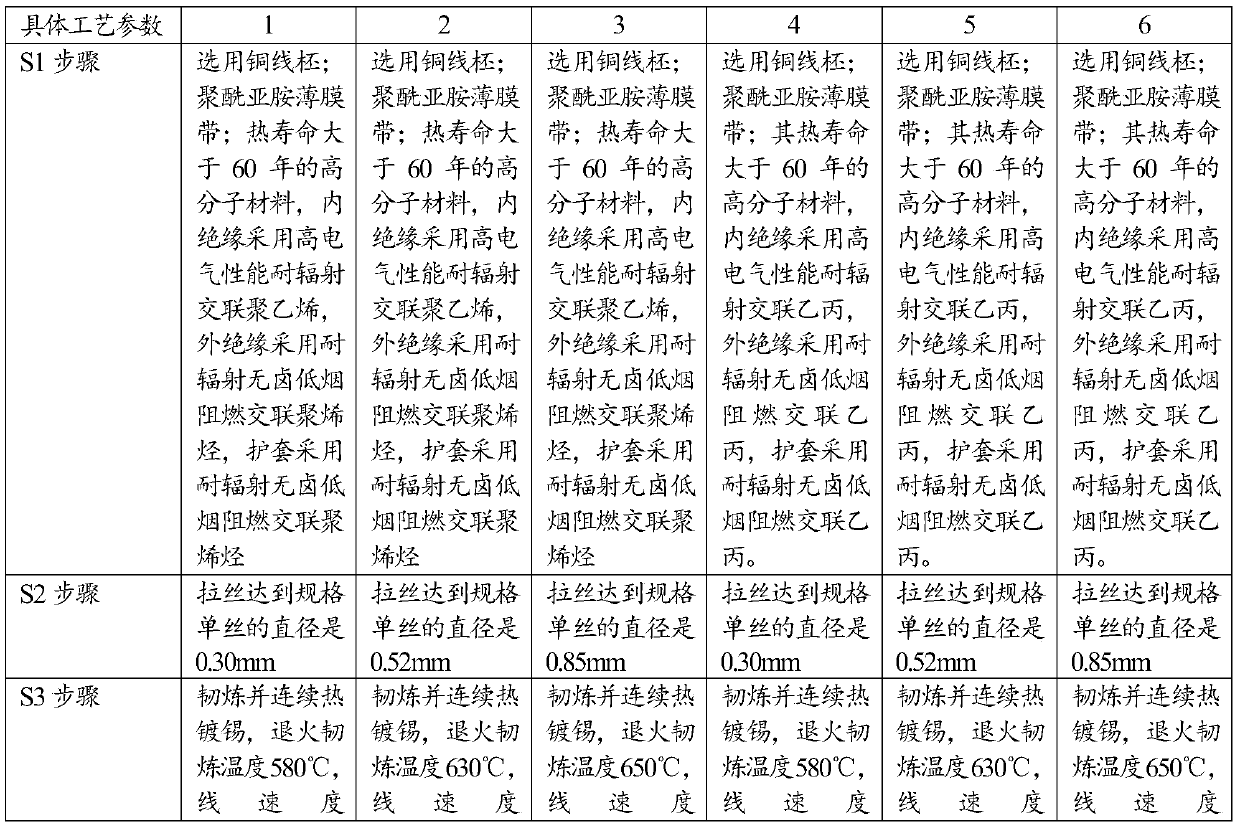

[0073] Set six groups of experimental groups, wherein experimental group 1-3 adopts the preparation method of embodiment 1, wherein experimental group 4-6 adopts the preparation method of embodiment 2, and the specific preparation process parameter control is shown in table 1

[0074] Table 1 Concrete preparation process parameter control table

[0075]

[0076]

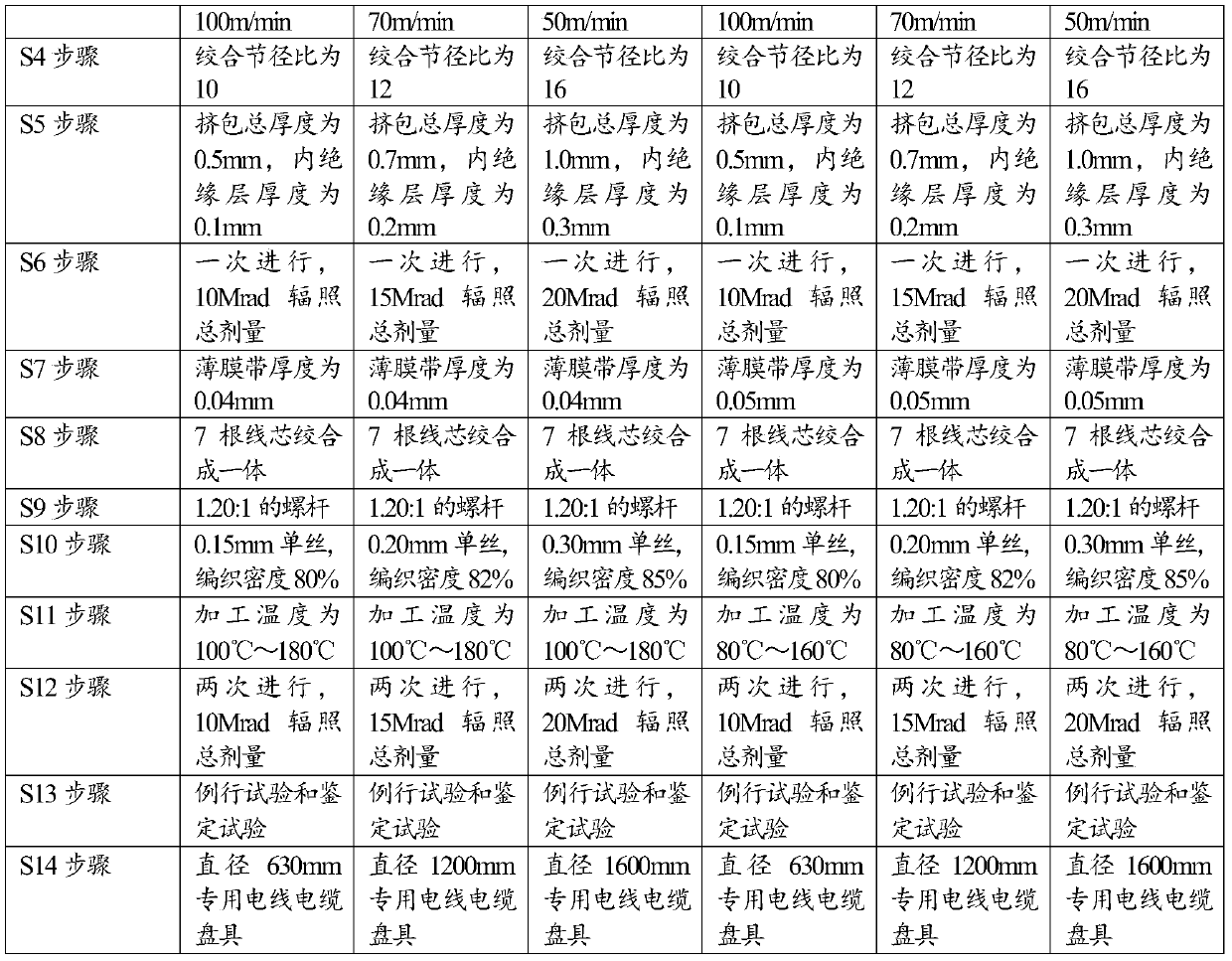

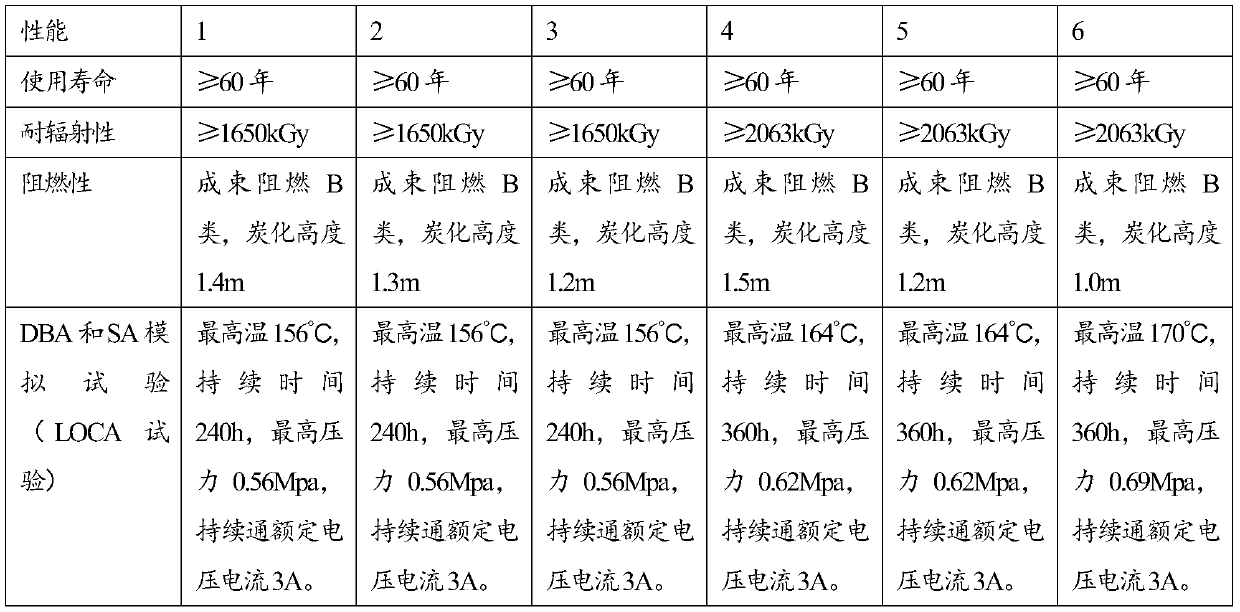

[0077] Then test the control cables used in the containment of the six experimental groups, and get the final performance test parameters Table 2

[0078] Detection parameter table 2

[0079]

[0080]

[0081] It can be seen from Table 2 that the performance of experimental group No. 6 is the best, and it is superior to other experimental group cables in terms of design service life, radiation resistance, flame retardancy and safety performance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com