A-grade fireproof formaldehyde-free plate and preparation method thereof

A formaldehyde-free board and fiber technology, applied in the field of decorative materials, can solve the problems of troublesome processing, inconvenient construction and high price, and achieve the effects of not easy to crack, good screw holding force and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

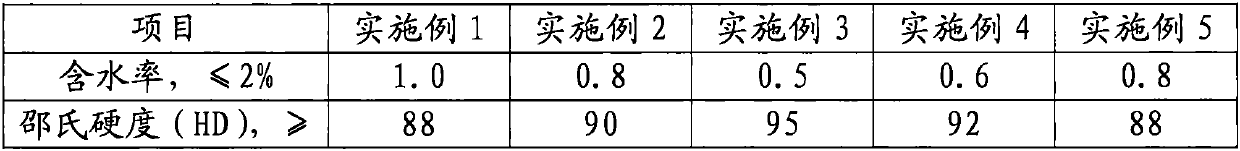

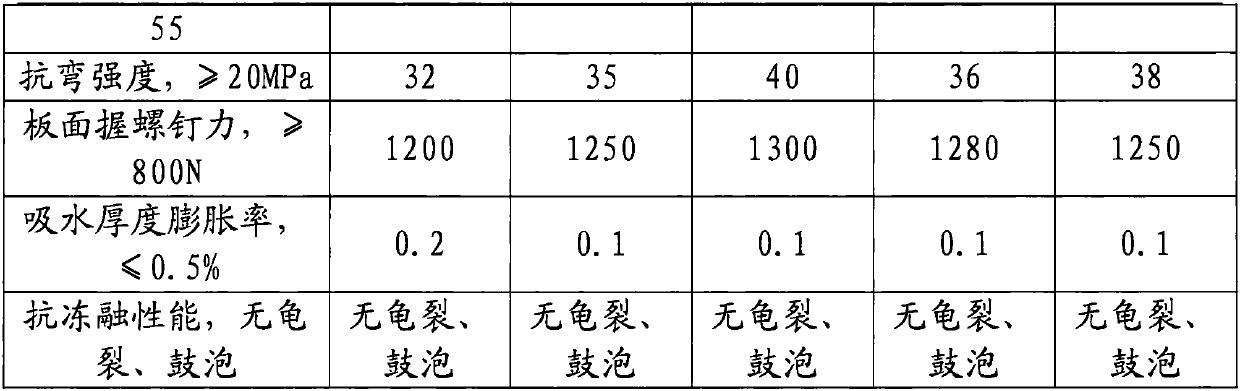

Examples

Embodiment 1

[0038] Class A fireproof formaldehyde-free board, made from raw materials of the following quality: wood fiber 15kg, bamboo charcoal powder 10kg, magnesium oxide 35kg, magnesium sulfate 25kg and amino acid 15kg.

[0039] The preparation method specifically comprises the following steps:

[0040] (1) Take each raw material by the above-mentioned quality;

[0041] (2) Magnesium oxide and magnesium sulfate are mixed to obtain mixed material A;

[0042] (3) Add wood fiber, bamboo charcoal powder, amino acid and water 80kg in step (2) gained mixed material A, stir 40min with the rotating speed of 300r / min, obtain mixed material B;

[0043] (4) Inject the mixed material B obtained in step (3) into a mold, press to form, and dry at 70°C for 120 minutes to obtain a grade A fireproof formaldehyde-free board.

Embodiment 2

[0045] Grade A fireproof formaldehyde-free board, made of the following quality raw materials: 25kg bamboo fiber, 20kg sawdust, 25kg magnesium hydroxide, 15kg calcium sulfate, 15kg amino acid.

[0046] The preparation method specifically comprises the following steps:

[0047] (1) Bamboo fibers were first dried at 60°C for 60 minutes, then pulverized and passed through a 50-mesh sieve; then each raw material was weighed by the above-mentioned quality;

[0048] (2) Magnesium hydroxide and calcium sulfate are mixed to obtain mixed material A;

[0049] (3) Add bamboo fiber, sawdust, amino acid and water 90kg in the mixed material A obtained in step (2), stir with the rotating speed of 350r / min for 35min, obtain mixed material B;

[0050] (4) Inject the mixed material B obtained in step (3) into a mold, press to form, and dry at 72°C for 110 minutes to obtain a grade A fireproof formaldehyde-free board.

Embodiment 3

[0052] Class A fire-proof formaldehyde-free board, made of the following quality raw materials: wood fiber 20kg, bamboo charcoal powder 15kg, magnesium oxide 30kg, magnesium sulfate 20kg, amino acid 15kg.

[0053] The preparation method specifically comprises the following steps:

[0054] (1) Dry the wood fiber at 65°C for 45 minutes, then pulverize it, and pass through a 100-mesh sieve; then weigh each raw material according to the above-mentioned quality;

[0055] (2) Magnesium oxide and magnesium sulfate are mixed to obtain mixed material A;

[0056] (3) Add wood fiber, bamboo charcoal powder, amino acid and water 100kg in step (2) gained mixed material A, stir 30min with the rotating speed of 400r / min, obtain mixed material B;

[0057] (4) Inject the mixed material B obtained in step (3) into a mold, press to form, and dry at 75°C for 100 minutes to obtain a grade A fireproof formaldehyde-free board.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com