Femtosecond Laser Cutting Method of Silicon Carbide

A femtosecond laser, cutting method technology, applied in laser welding equipment, sustainable manufacturing/processing, final product manufacturing, etc., can solve the problems of long processing time, low cutting accuracy, large material loss, etc., to avoid cracks and damages , the preparation cycle is short, the effect of avoiding waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with embodiment further illustrate the present invention, but the present invention is not limited to this embodiment.

[0016] The invention discloses a femtosecond laser cutting method for silicon carbide, which specifically includes the following steps:

[0017] 1) Ultrasonic the SiC wafer in alcohol for 15 minutes, dry it naturally and fix it on the three-dimensional precision processing table;

[0018] 2) The laser beam (wavelength 800nm, pulse width 130fs-150fs, repetition rate 1000Hz, average power 725mW, single pulse energy 0.725mJ, spot radius 2mm) produced by the femtosecond laser is adjusted by a beam expander collimator and focused (f= 30mm) onto the SiC wafer on the processing table;

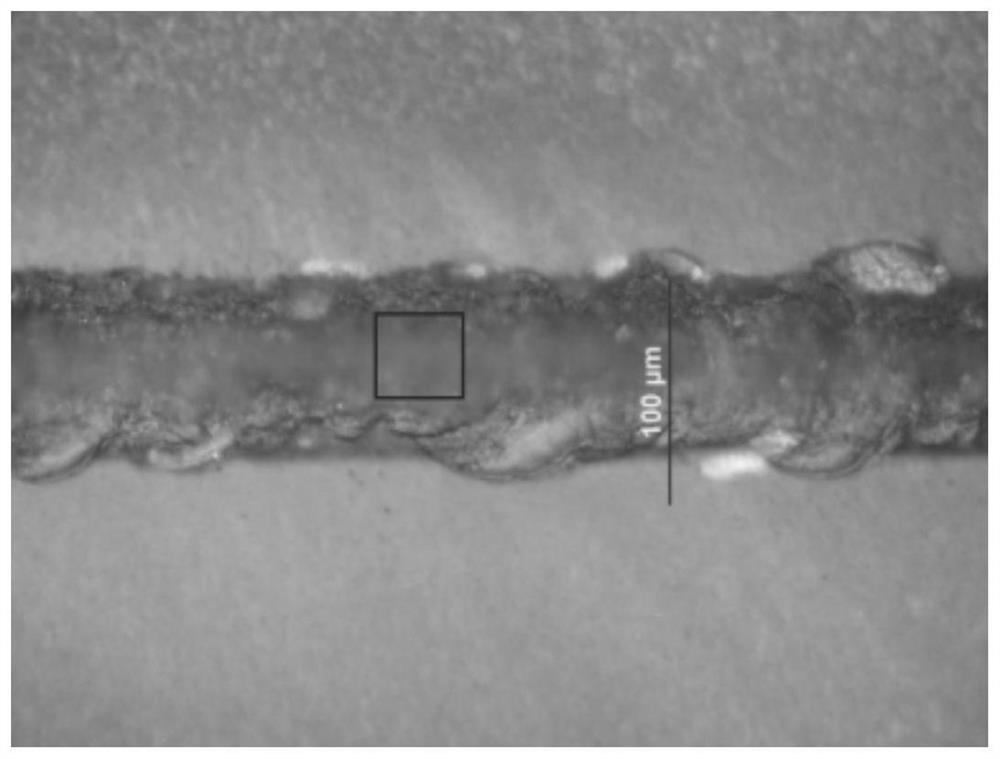

[0019] 3) Set the movement rate of the three-dimensional precision machining table to 3mm / s, so that the SiC wafer is scanned by the femtosecond laser at the focal plane in a single pass to realize cutting. Raman spectra of wafers before and after dicin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mohs hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com