Lamelleted graphite carbon nitride/montmorillonoid composite material as well as preparation method and application thereof

A composite material, phase carbon nitride technology, applied in chemical instruments and methods, alkali metal compounds, alkali metal oxides/hydroxides, etc., can solve the problems of difficult separation, easy agglomeration of materials, and increased adsorption capacity of heavy metal ions. , to achieve the effects of environmental friendliness, simple preparation steps and mild conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

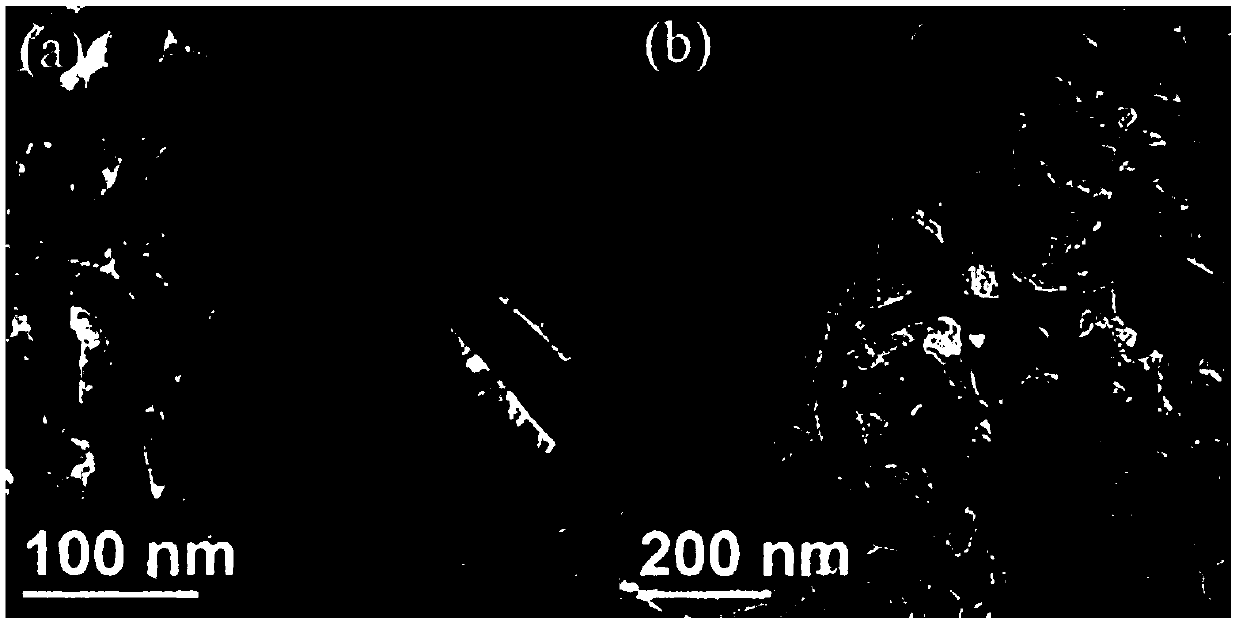

[0032] (1) Layered g-C 3 N 4Preparation of nanosheets: Take 5g of melamine and lay it flat on a ceramic ark, wrap the ark with tin foil to form a fully closed system and put it into a tube furnace for calcination. Control the heating rate from room temperature to 5°C / min, and the holding time to 3h , after naturally cooling to room temperature, the yellow product was ground into powdery particles to obtain bulk carbon nitride; the above-mentioned small amount of bulk carbon nitride was spread in a ceramic ark to form a semi-closed system and put into a muffle furnace for heating Oxidation treatment, heat preservation at 500°C for 3 hours, and natural cooling to room temperature, to obtain loose light yellow g-C 3 N 4 ; take 5g g-C 3 N 4 Disperse the particles in 100mL isopropanol solution, ultrasonically treat with running water for 3 hours; then centrifuge to obtain a light yellow sediment; dry in an oven at 70°C for 12 hours, grind the light yellow sediment into powder p...

Embodiment 2

[0037] Weigh 0.1 g of adsorbents with different compound ratios, layered g-C 3 N 4 Nanosheets and Na-montmorillonite were added to 100 mL of lead nitrate solution with an initial concentration of 100 mg / L, and the pH of the solution was 5.0. Stir at room temperature for 2 h, then centrifuge (4000 r / min). The supernatant obtained by centrifugation was diluted 10 times, its concentration was measured under an atomic absorption spectrophotometer, and the concentration of remaining lead ions was calculated.

[0038] The results showed that layered g-C 3 N 4 Layered g-C with mass percentage of 0.5%, 1.0%, 2.0%, 5.0%, 10.0% 3 N 4 / The adsorption capacity of montmorillonite composites to lead ions was 59.05mg / g, 75.64mg / g, 95.36mg / g, 74.25mg / g, 57.03mg / g, and the removal rates were 59.05%, 75.64%, 95.36% %, 74.25%, 57.03%, layered g-C 3 N 4 The adsorption capacity of nanosheets to lead ions is 10.12 mg / g, and the removal rate is 10.12%. The adsorption capacity of sodium mont...

Embodiment 3

[0040] Same as the steps in Example 2, the difference is that the adsorbent is layered g-C 3 N 4 2.0% by mass of layered g-C 3 N 4 / Montmorillonite composite material, the pH values adjusted by 100mg / L lead nitrate solution are 1.0, 2.0, 3.0, 4.0 respectively, and the dilution times after centrifugation are 20, 20, 20, 20 times respectively.

[0041] The results showed that layered g-C 3 N 4 2.0% by mass of layered g-C 3 N 4 / When the pH value of montmorillonite composite material is 1.0, 2.0, 3.0, 4.0, the adsorption capacity of lead ion is 25.25mg / g, 30.05mg / g, 50.13mg / g, 60.26mg / g, and the removal rate is 25.25%. , 30.05%, 50.13%, 60.26%. Depend on Figure 5 It can be seen that the adsorbent layered g-C 3 N 4 2.0% by mass of layered g-C 3 N 4 The / montmorillonite composite material has the best adsorption effect on Pb(Ⅱ) in the lead nitrate aqueous solution with pH 5.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adsorption capacity | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com