Zirconium matrix removing process and burnup measuring method adopting same

A measurement method and matrix technology, applied in nuclear engineering, greenhouse gas reduction, nuclear reactor monitoring, etc., can solve problems such as data deviation from the true value, burnup measurement failure, and affect the separation effect of uranium and burnup monitoring body, etc., to achieve wide application and promotional value effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

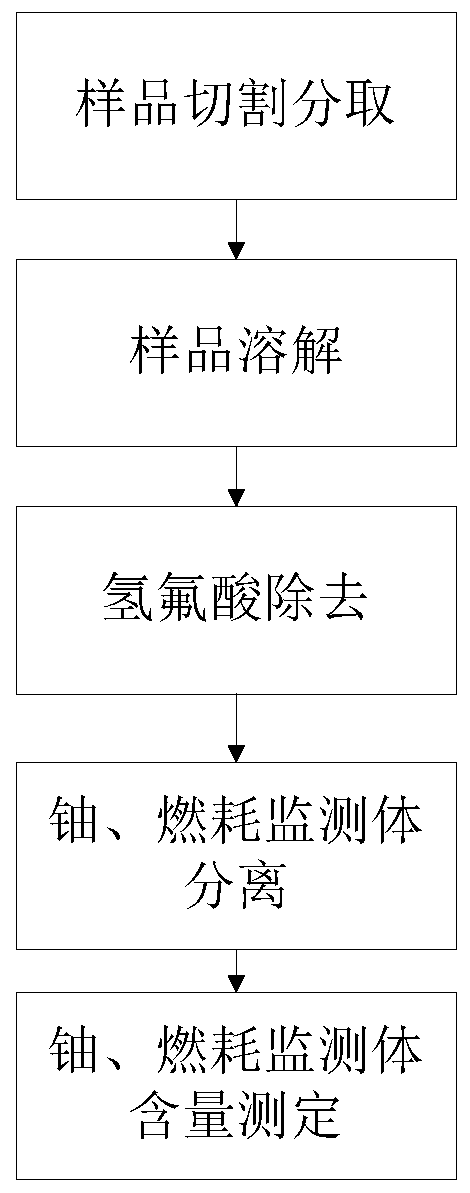

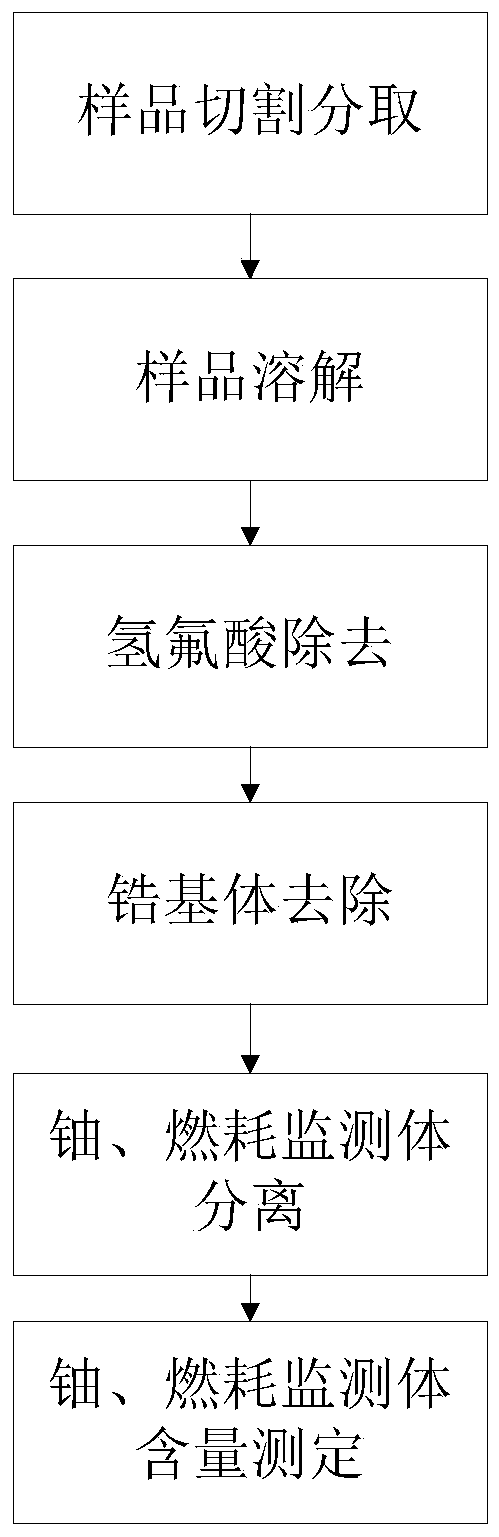

[0065] Such as figure 2 The burnup measurement method using the zirconium matrix removal process shown includes the steps of sample cutting and fractionation, sample dissolution step, hydrofluoric acid removal step, uranium and burnup monitoring body separation step, and uranium and burnup monitoring body content determination step ; Also includes a zirconium matrix removal step, the zirconium matrix removal step is located between the hydrofluoric acid removal step and the uranium, burnup monitoring body separation step; the solution obtained through the zirconium matrix removal step can be directly used for uranium, burnup monitoring body separation step.

[0066] Through the zirconium matrix removal process, the burnup measurement process provided by the present invention can remove a large amount of zirconium matrix in the solution after the hydrofluoric acid removal step, so that the zirconium content in the solution is lower than the subsequent separation steps of urani...

Embodiment 2

[0068] On the basis of Example 1, the step of removing the zirconium matrix comprises the following steps:

[0069] (A) adjustment of the solution system, adjusting the solution Y1 obtained in the hydrofluoric acid removal step to obtain the solution Y2 of the zirconium matrix to be removed;

[0070] (B) Extracting the zirconium matrix in the solution Y2 with an extractant solution to obtain a solution Y3.

[0071] Wherein, described step (A) comprises the following steps:

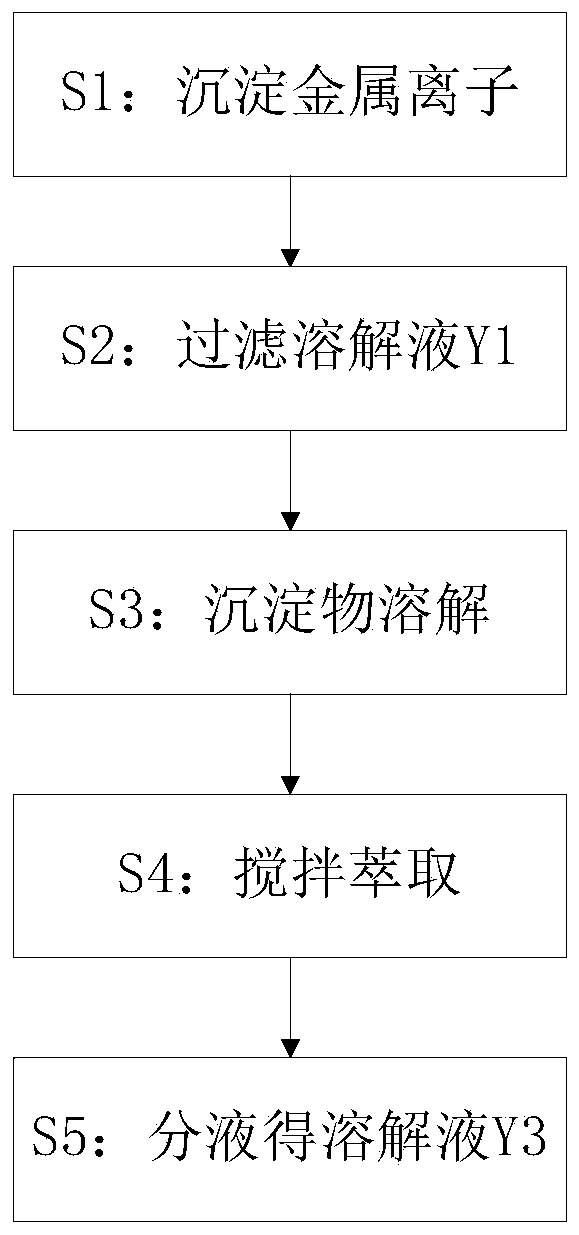

[0072] (A1) Precipitating metal ions, adding ammonia water to the solution Y1, and precipitating the metal ions in the solution Y1;

[0073] (A2) filtering the solution Y1 to obtain the metal ion precipitate generated in the step (A1);

[0074] (A3) The precipitate is dissolved, and the precipitate obtained by filtering in the step (A2) is dissolved with nitric acid to obtain a solution Y2.

[0075] Since the solution obtained after the hydrofluoric acid removal step is a mixed acid system of nitric acid ...

Embodiment 3

[0081] On the basis of embodiment 2, step (B) comprises the following steps:

[0082] (B1) placing the extractant solution and the solution Y2 together in a reaction vessel, stirring and extracting the zirconium matrix in the solution Y2;

[0083] (B2) Stand still, discard the upper organic phase, and the lower aqueous phase is the solution Y3, which can be directly used in the separation step of uranium and burnup monitoring body.

[0084] Wherein, in step (B1), the extraction temperature is 20-30° C., and the extraction time is 10-30 min.

[0085] After the extraction and stirring, take out the reaction vessel from the water bath environment and let it stand for 2 to 5 minutes, then discard the upper organic phase, which contains the zirconium matrix; the lower aqueous phase is the solution Y3, which has a low zirconium content It is less than 0.1g / L, so it can be directly used in the separation process of uranium and burnup monitoring body for subsequent burnup measurement...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com