Low-zirconium-content sintered tabular corundum and preparation method thereof

A technology of platy corundum and zirconium content, applied in the field of refractory materials, can solve the problems of uneven distribution, high preparation cost, large grain size, etc., and achieve the effect of simple process operation, simple preparation process and good thermal shock stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~6

[0035] A method for preparing sintered tabular alumina with low zirconium content, comprising the steps of:

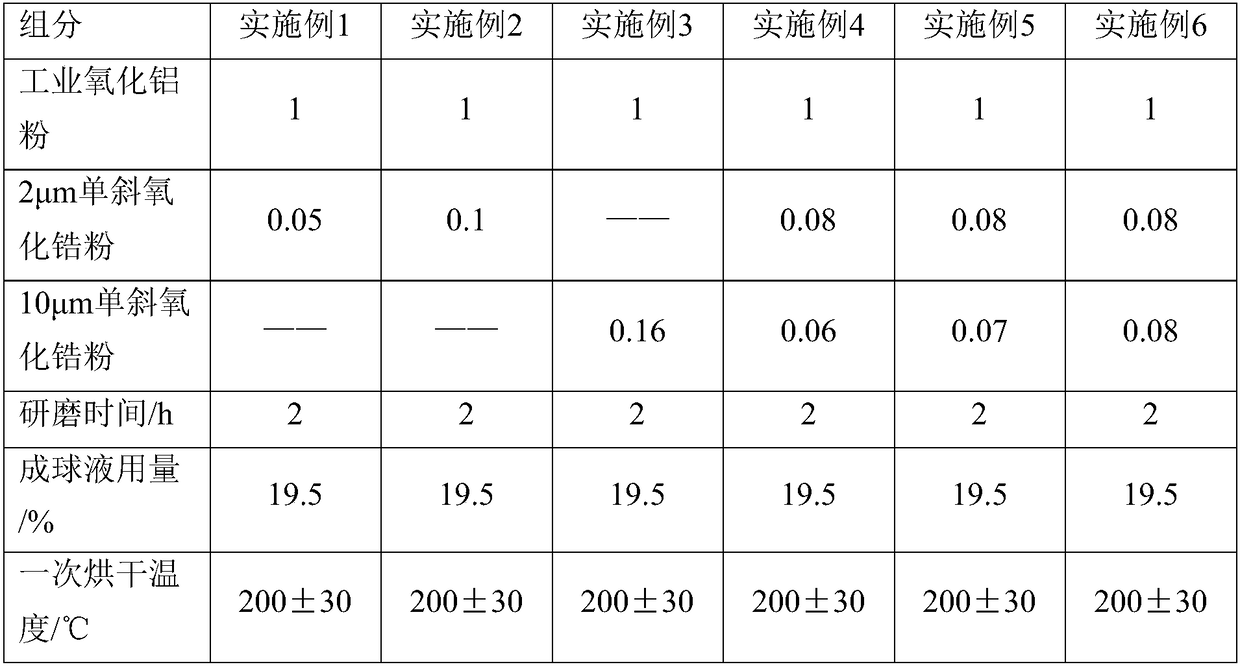

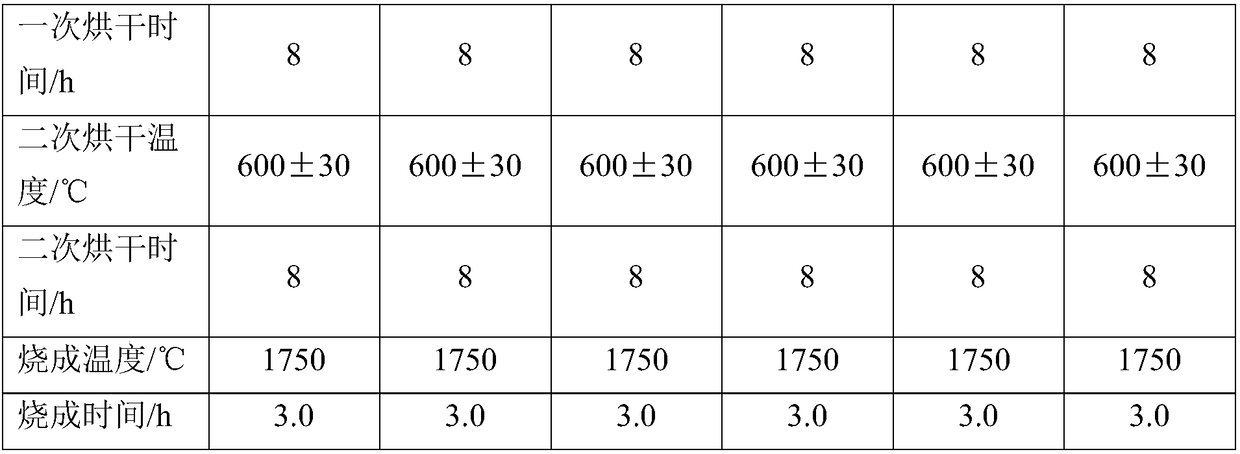

[0036] (1) Put industrial alumina powder and monoclinic zirconia powder in different silos, and each silo is connected to the ball mill through its own pipeline. The feed quality of industrial alumina powder and monoclinic zirconia powder is such as Table 1 shows.

[0037] The main component of industrial alumina is γ-alumina, and the mass fraction of each component in industrial alumina powder is Al 2 o 3 ≥98.0%, SiO 2 ≤0.10%, CaO≤0.15%, Fe 2 o 3 ≤0.1%, Na 2 O≤0.5%.

[0038] Table 1, 2μm monoclinic zirconia powder, D 50 =1.8-2.3μm, ZrO 2 Mass fraction>99.0%; in 10μm monoclinic zirconia powder, D 50 =10-15μm, ZrO 2 Mass fraction > 98.5%.

[0039] (2) Industrial alumina powder and monoclinic zirconia powder are ground in a ball mill, and the grinding time is shown in Table 1.

[0040] (3) After grinding, put it into the ball forming tray, and spray water int...

Embodiment 4

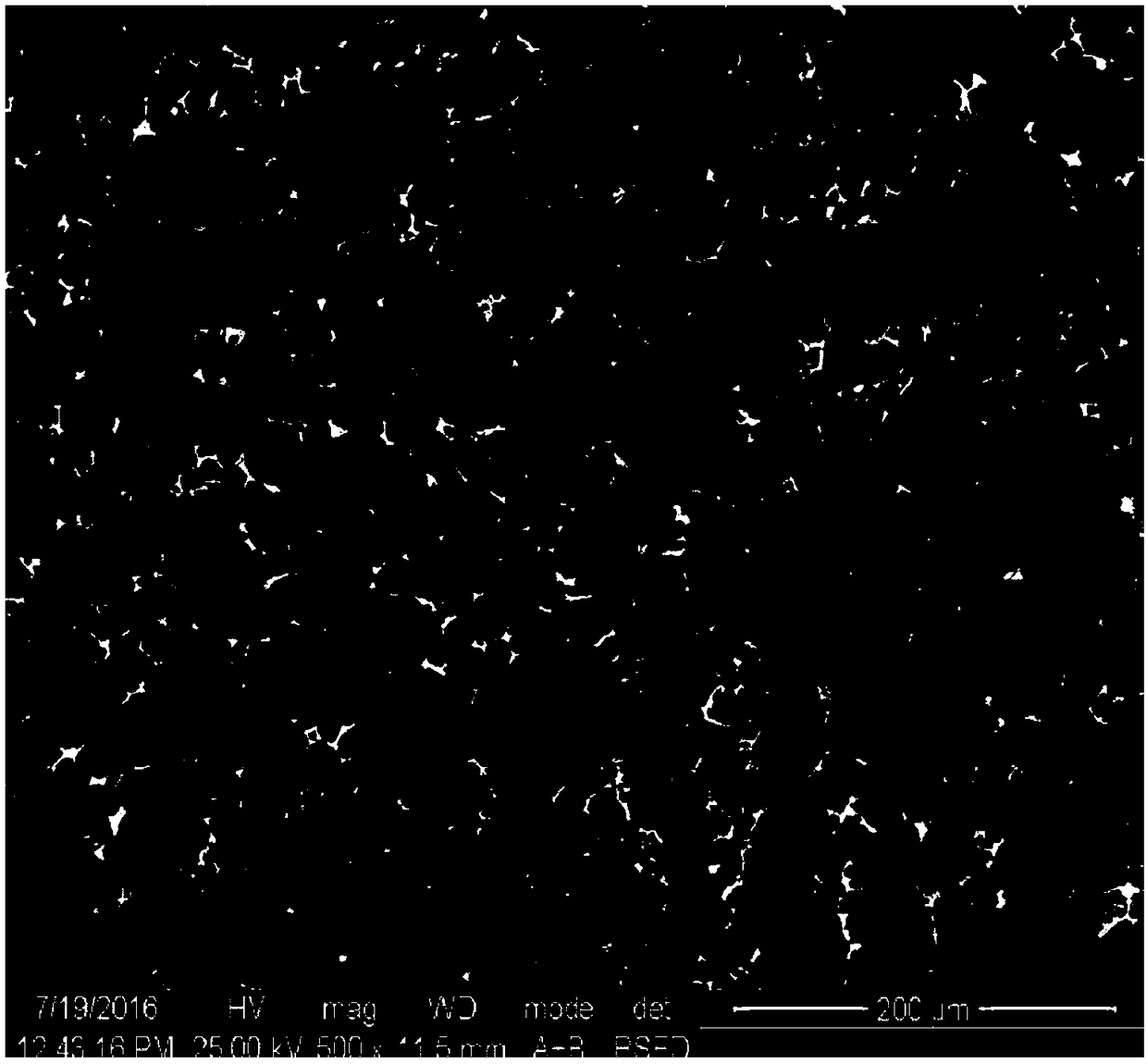

[0062] The electron microscope figure of embodiment 4 is as figure 1 shown, from figure 1 It can be seen that the average size of corundum grains is 30-40 μm, and the white area is ZrO 2 Grains, ZrO 2 The grain size is 1.0--9μm, ZrO 2 The grain size is uniform, and the ZrO2 grains are evenly distributed in the junction of corundum grains and grains.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com