Spray deposition mos under the action of electric field force assisted by temperature control device 2 /ti composite film

A technology of temperature control device and auxiliary electric field, applied in metal material coating process, coating and other directions, can solve the problems of limited film thickness range, poor adaptability to atmospheric environment, high manufacturing cost, etc., achieve universal applicability, improve film base The effect of combining strength and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

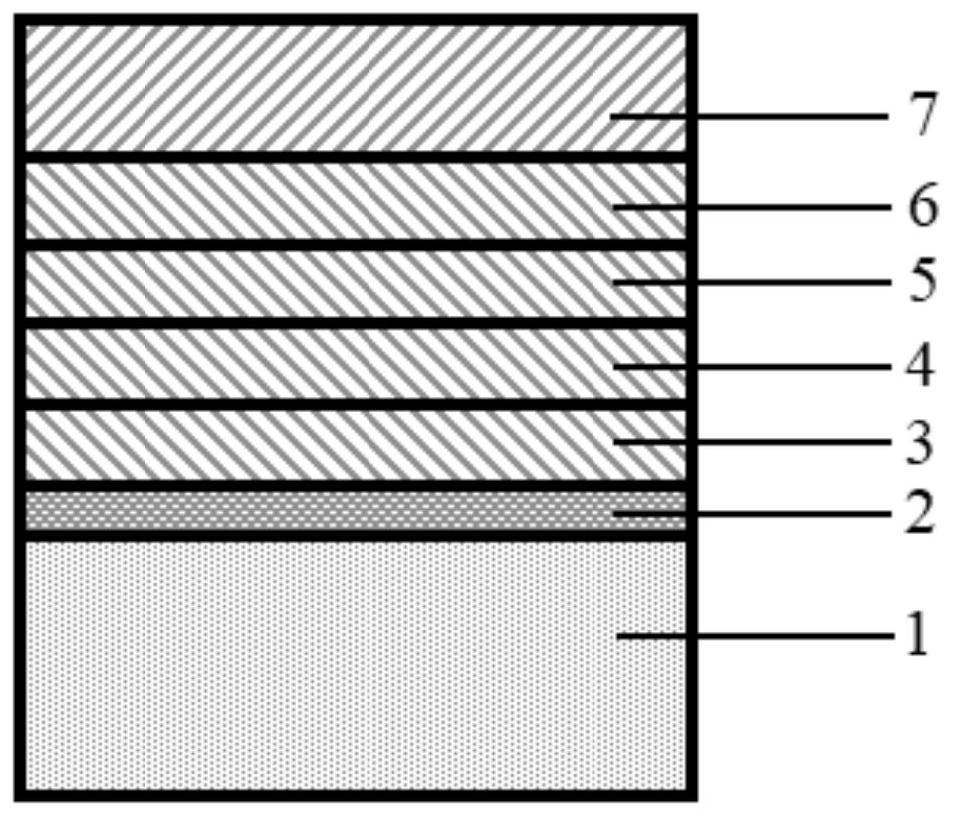

[0063] The second purpose of this application is to propose a MoS 2 / Ti composite gradient film and its preparation method, the suspension is in a high-voltage electric field, under the action of electric field force and mechanical force, it will be atomized into stable nano-scale droplets, and deposits on the surface of the substrate have higher film-base bonding strength and good Anti-friction performance of MoS 2 / Ti composite gradient film. Its preparation process steps are as follows:

[0064] (1) Add different masses of molybdenum disulfide powder, titanium powder and binder to the same amount of solvent, and stir magnetically for 20 hours to obtain Ti suspension, MoS 2 / Ti(20%) suspension, MoS 2 / Ti(10%) suspension, MoS 2 / Ti(5%) suspension and MoS 2 suspension;

[0065] (2) First, prepare a Ti transition layer on the surface of the substrate, and the optimized preparation parameters are: the electric field strength is 7×10 5 V / m, the flow rate of Ti suspension i...

Embodiment 1

[0075] Spray deposition of MoS by electric field force assisted by a temperature control device 2 / Ti composite thin film method, its preparation process steps are as follows:

[0076] (1) Pre-treat the surface of the substrate, grind and polish the surface of cemented carbide YG6 (mainly composed of WC and Co) to a mirror surface, and ultrasonically clean it in acetone and absolute ethanol solutions for 20 minutes respectively.

[0077] (2) Add 0.5gMoS 2 The powder, 0.05g of Ti powder, 0.1g of ethyl cellulose and 2.5g of absolute ethanol were mixed in a certain proportion, and fully stirred with a magnetic stirrer for 20 hours to obtain a suspension with a certain viscosity.

[0078] (3) Set the parameters of feed system 1 so that the suspension is 1×10 -10 m 3 ·s -1 The flow rate flows out from the metal spray needle 6 through the rubber hose 4, and forms a stable micron-scale "cone-jet" in the electric field to atomize nano-scale droplets; the hard alloy substrate 7 is ...

Embodiment 2

[0082] Spray deposition of MoS by electric field force assisted by a temperature control device 2 / Ti composite thin film method, its preparation process steps are as follows:

[0083] (1) Pre-treat the surface of the substrate, grind and polish the surface of cemented carbide YG6 (mainly composed of WC and Co) to a mirror surface, and ultrasonically clean it in acetone and absolute ethanol solutions for 20 minutes respectively.

[0084] (2) Add 0.5gMoS 2 The powder, 0.125g of Ti powder, 0.1g of ethyl cellulose and 2.5g of absolute ethanol were mixed in a certain proportion, and fully stirred with a magnetic stirrer for 20 hours to obtain a suspension with a certain viscosity.

[0085] (3) Set the parameters of feed system 1 so that the suspension is 1.5×10 -10 m 3 ·s -1 The flow rate flows out from the metal spray needle 6 through the rubber hose 4, and forms a stable micron-scale "cone-jet" in the electric field to atomize nano-scale droplets; the cemented carbide substr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com