Laser composite repair method for surface corrosion of inner hole of shell

A composite repair and inner hole technology, which is applied in laser welding equipment, coating, metal material coating process, etc., can solve the problem that the inner hole surface roughness and air tightness test are difficult to meet the requirements, and the inner hole repair is difficult to implement laser cladding. It is difficult to accurately deliver the cladding powder to the repaired part, etc., so as to achieve the effect of small thermal deformation, small thermal influence and thermal damage, and improve the repair quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below in conjunction with the accompanying drawings and embodiments.

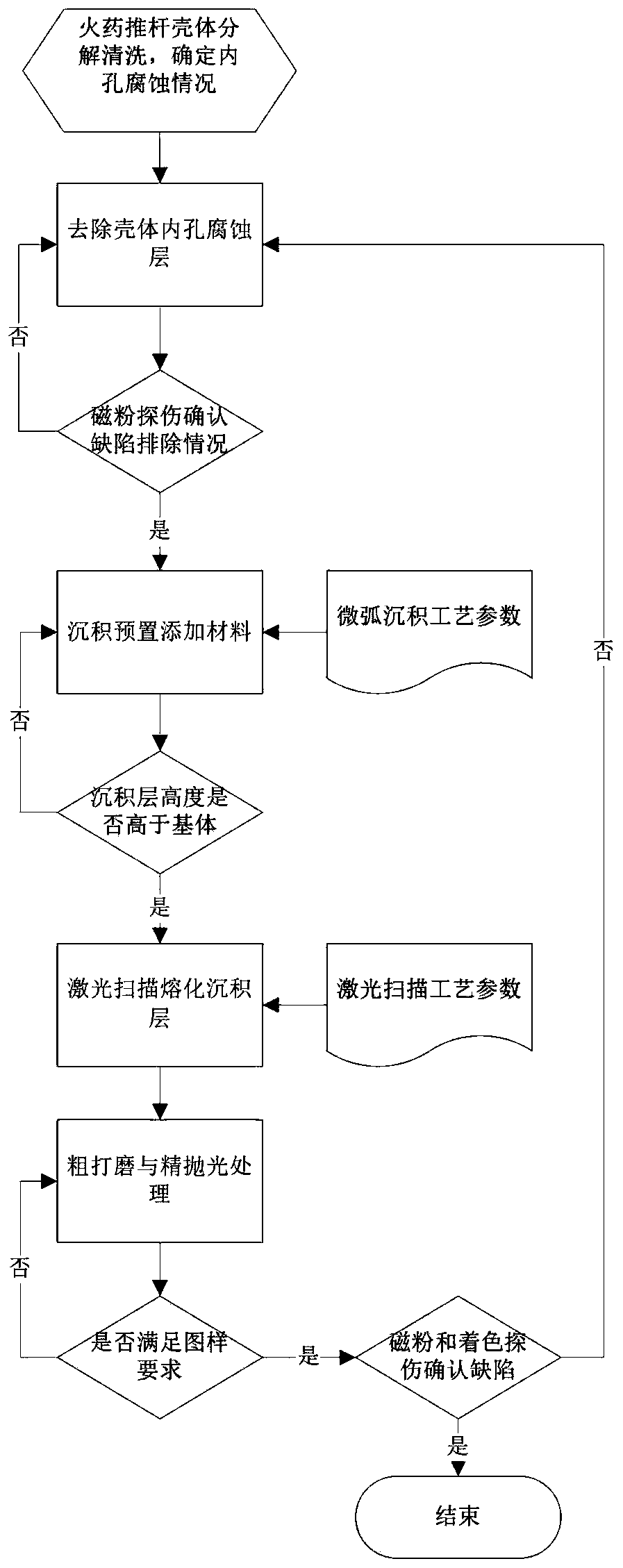

[0028] Such as figure 1 As shown, a laser composite repair method for the surface corrosion of the inner hole of the shell includes the following steps:

[0029] (1) Decompose and clean the surface of the inner hole of the gunpowder push rod shell, measure the size, and determine the local corrosion position and corrosion amount of the inner hole.

[0030] (2) According to the test results, the shell of the propellant push rod is analyzed and its life is evaluated, and the corrosion layer in the inner hole of the shell is removed.

[0031] (3) Use magnetic particle inspection to ensure that there are no crack defects after removing the corrosion layer. If there are crack defects, repeat step (2) until it is ensured that ther...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com