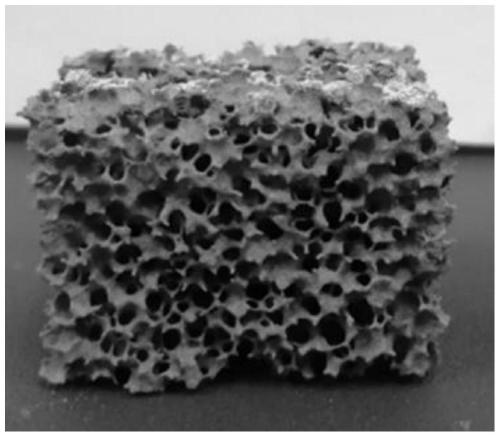

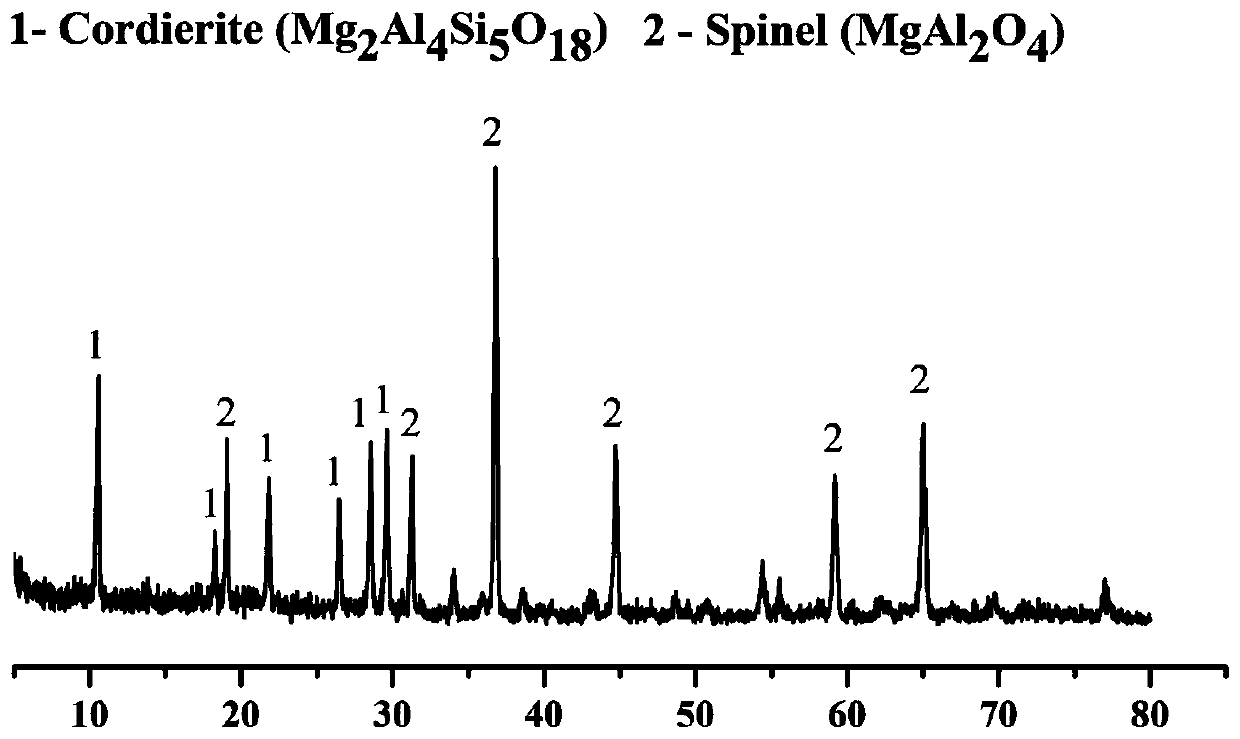

Three-dimensional reticulated spinel-cordierite porous ceramic with high porosity and preparation method thereof

A technology of three-dimensional network and porous ceramics, which is applied in the direction of ceramic products, ceramic material production, clay products, etc., can solve the problems of difficult control of porosity, low porosity, difficult to control shrinkage, etc., to increase porosity and reduce sintering temperature , the effect of improving the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

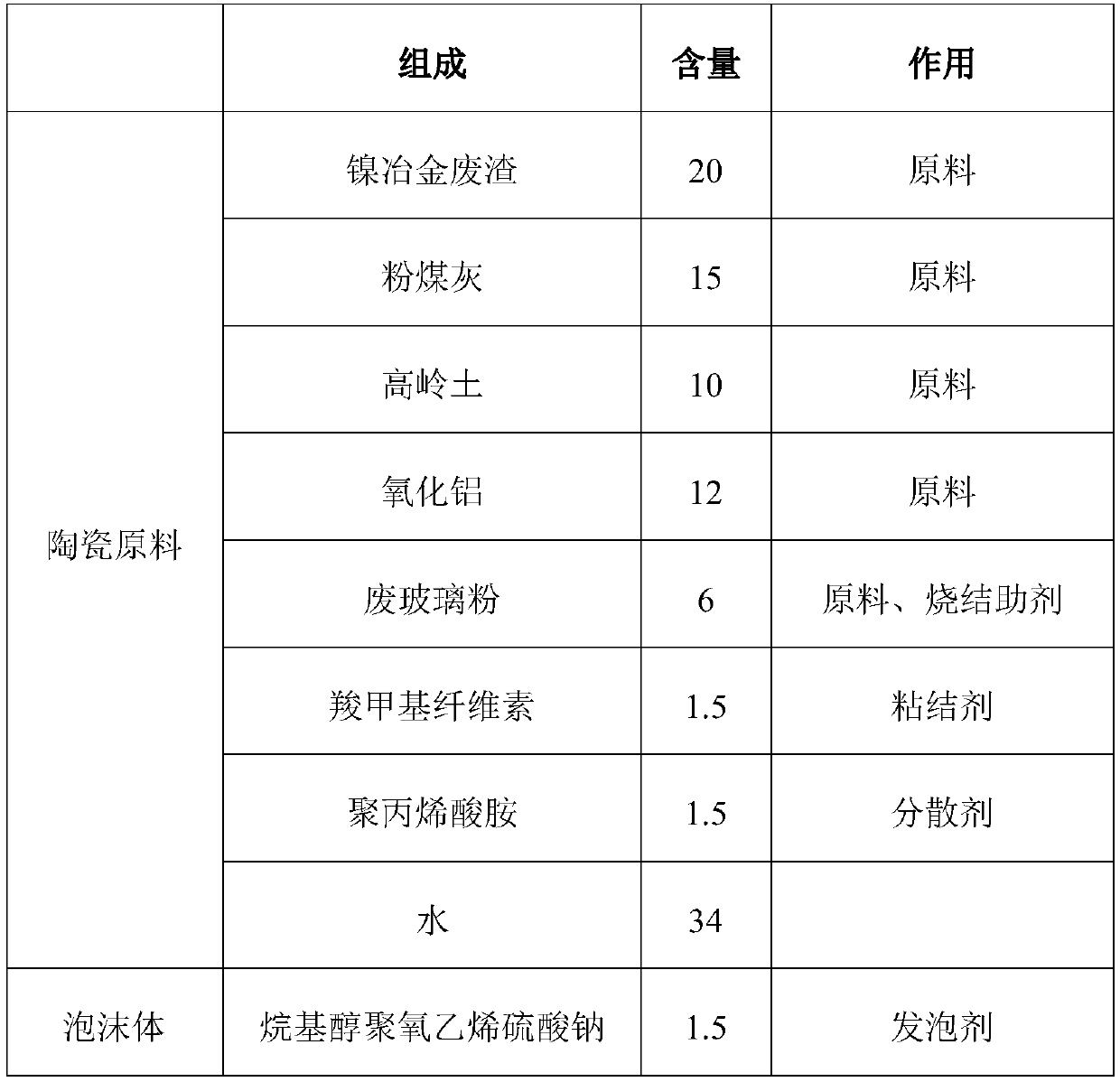

[0031] The high porosity three-dimensional reticular spinel-cordierite porous ceramic components, contents and functions of this embodiment are shown in Table 1 below, and the raw materials in the table are all calculated by weight percentage; wherein the particle size of nickel metallurgical waste slag is more than or equal to 200 mesh, nickel alloy MgSiO in waste residue 3 and Mg 2 SiO 4 The sum of the percentages by weight ≥ 85%; the fly ash is secondary fly ash with a fineness ≥ 350 mesh; the fineness of waste glass powder ≥ 350 mesh, and the Na in waste glass powder 2 The weight percentage of O is more than or equal to 20%.

[0032] Component, content and effect of table 1 embodiment 1 porous ceramics

[0033]

[0034]

[0035] The preparation method of the high-porosity three-dimensional network spinel-cordierite porous ceramic in this embodiment is divided into two parts: precursor preparation and ceramic green body sintering, including the following steps:

...

Embodiment 2

[0043]The high porosity three-dimensional reticulated spinel-cordierite porous ceramic components, contents and functions of this embodiment are shown in Table 2 below, and the raw materials in the table are all calculated by weight percentage; wherein, wherein the nickel metallurgical waste slag particle size is ≥ 200 mesh, MgSiO in nickel alloy waste slag 3 and Mg 2 SiO 4 The sum of the percentages by weight ≥ 85%; the fly ash is secondary fly ash with a fineness ≥ 350 mesh; the fineness of waste glass powder ≥ 350 mesh, and the Na in waste glass powder 2 The weight percentage of O is more than or equal to 20%.

[0044] Component, content and effect of table 2 embodiment 2 porous ceramics

[0045]

[0046]

[0047] The preparation method of the high-porosity three-dimensional network spinel-cordierite porous ceramic in this embodiment is divided into two parts: precursor preparation and ceramic green body sintering, including the following steps:

[0048] (1) Spong...

Embodiment 3

[0054] The high-porosity three-dimensional reticular spinel-cordierite porous ceramic components, contents and functions of this embodiment are shown in Table 3 below, and the raw materials in the table are all calculated by weight percentage; wherein, the nickel metallurgical waste slag has a particle size of ≥200 mesh, MgSiO in nickel alloy waste slag 3 and Mg 2 SiO 4 The sum of the percentages by weight ≥ 85%; the fly ash is secondary fly ash with a fineness ≥ 350 mesh; the fineness of waste glass powder ≥ 350 mesh, and the Na in waste glass powder 2 The weight percentage of O is more than or equal to 20%.

[0055] Component, content and effect of the porous ceramic of table 3 embodiment 3

[0056]

[0057] The preparation method of the high-porosity three-dimensional network spinel-cordierite porous ceramic in this embodiment is divided into two parts: precursor preparation and ceramic green body sintering, including the following steps:

[0058] (1) Sponge template...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com