Preparation method and energy storage material of multiple conductive ceramic materials

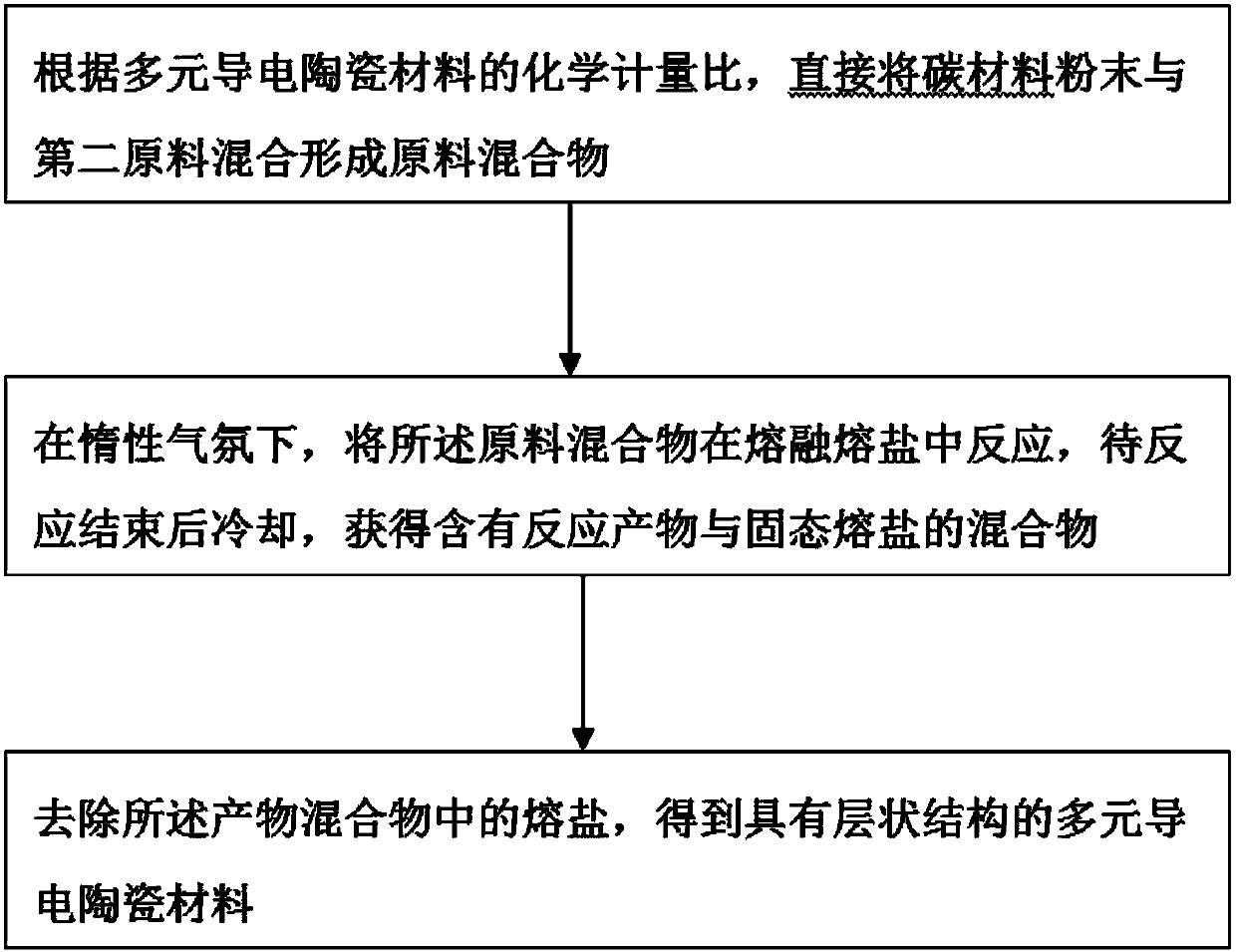

A technology for conductive ceramic materials and battery materials, applied in circuits, electrical components, battery electrodes, etc., can solve the problems of complex preparation process and equipment, high synthesis temperature and high cost of ternary conductive ceramic materials, and achieve low cost of raw materials, convenient The effect of mass production and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0038] Weigh 20 unit weight (for example, kilogram) of NaCl-KCl eutectic salt, and mix it with 1.2 unit weight of Ti powder, 0.23 unit weight of Al powder, and 0.2 unit weight of nano-C powder (average particle size 50nm). Place it in a corundum crucible. Place the crucible above in a stainless steel reactor, seal it and protect it with Ar gas. Use a temperature controller to heat up to 900°C at a rate of 5°C / min, keep it at this temperature for 2h, and then cool down to room temperature with the furnace after power off. The obtained product is taken out, rinsed with deionized water to remove residual molten salt, and then dried at low temperature to obtain the target product.

[0039] Test the obtained target product, and its XRD pattern, SEM and TEM photos are as follows: figure 2 , 3 And shown in 4. by figure 2 It can be seen that the obtained nano powder is Ti 3 AlC 2 , After further testing, the resultant product contains Ti 3 AlC 2 The particle size of the nano powder i...

example 2

[0041] Weigh 20 unit weight of LiCl-KCl eutectic salt and mix it with 1.2 unit weight of Ti powder, 0.25 unit weight of Al powder, and 0.2 unit weight of nanometer acetylene black powder (average particle size 40nm), and place the mixture in a corundum crucible . Place the crucible above in a stainless steel reactor, seal it and protect it with Ar gas. Use a temperature controller to heat up to 850°C at a rate of 8°C / min, keep it at this temperature for 5 hours, and then cool down to room temperature with the furnace after power off. Take out the resulting product, soak and rinse with deionized water to remove residual molten salt, and then dry at low temperature to obtain Ti 3 AlC 2 Nano powder.

example 3

[0043] Weigh 40 units of CaCl 2 -NaCl eutectic salt, and mixed with 0.8 unit weight of Ti powder, 0.293 unit weight of Al powder, 0.09 unit weight of nanometer acetylene black powder (average particle size 40nm), and place the mixture in a corundum crucible. Place the crucible above in a stainless steel reactor, seal it and protect it with Ar gas. Use a temperature controller to heat up to 950°C at a rate of 10°C / min, keep it at this temperature for 3h, and then cool down to room temperature with the furnace after power off. The obtained product is taken out, rinsed with deionized water to remove residual molten salt, and then dried at low temperature to obtain the target product.

[0044] Test the obtained target product, and its XRD pattern, SEM and TEM photos are as follows: Figure 5 , 6 And 7 are shown. by Figure 5 It can be seen that the obtained nano powder is Ti 2 AlC, after further testing, the resultant product contains Ti 2 The particle size of the AlC nano powder is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com