Alginate complex gel stent material constructed based on homogeneous phase crosslinking and layer-by-layer self-assembly technology and preparation method thereof

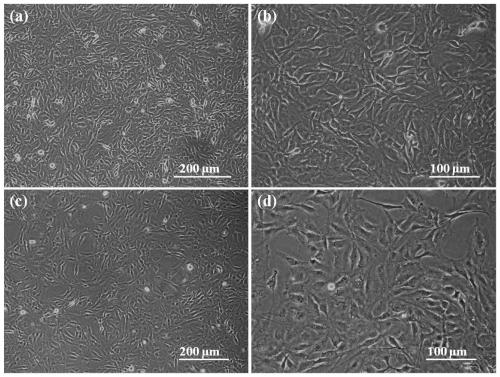

A layer-by-layer self-assembly and alginate technology, which is applied in the fields of pharmaceutical formulations, medical science, prostheses, etc., can solve the problems of lack of cell-specific binding sites, poor mechanical properties, and low gel stability, and achieve benefits Proliferation and osmotic growth, effects of good 3D topography

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

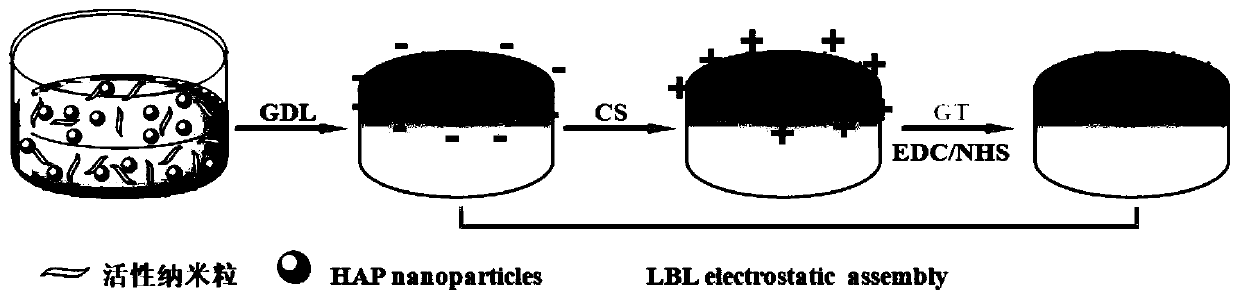

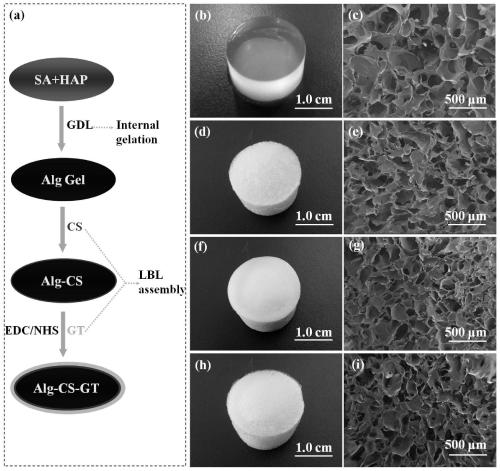

[0053] A kind of Alg / SiO 2 -The specific steps of the preparation method of the CS-GT scaffold material are:

[0054] Preparation of soaking flushing solution: prepare chitosan (CS) solution with a mass fraction of 1% and gelatin (GT) solution with a mass fraction of 1.5% in 0.005mol / L calcium chloride solution for standby.

[0055] Accurately weigh 2.0g SA and dissolve it in 100mL deionized water, and prepare a SA transparent solution with a mass fraction of 2% under electric stirring. Then add 2.0 g SiO to the solution 2 The nanoparticles and 365.2 mg of HAP powder were stirred at high speed (8000-12000 rpm, the same below) for 2 hours under the action of ultrasound to obtain a uniform mixed solution. Use a 30mL hypodermic syringe to pipette 15mL of the mixture into a 50mL beaker. Under the action of magnetic stirring, 194.4 mg GDL was added to initiate ion cross-linking, and after stirring at high speed for 2 minutes, it was quickly transferred to a 12-well tissue cultur...

Embodiment 2

[0059] A kind of Alg / SiO 2 -The specific steps of the preparation method of the CS-SP scaffold material are:

[0060] With HAP / GDL complex as cross-linking agent, SiO 2 Nanoparticles are reinforcing agents, and the alginate composite gel scaffold material is prepared through layer-by-layer assembly between biomacromolecules. In the preparation of the material, the molar ratio of HAP to GDL was fixed at 1:10, and the molar ratio of Ca in HAP to –COOH in SA was 0.18.

[0061] Preparation of immersion flushing solution: prepare CS solution with a mass fraction of 0.6% and sericin (SP) solution with a mass fraction of 1.0% in 0.01 mol / L calcium chloride solution for standby.

[0062] Under mechanical stirring and ultrasound, 1.0 g SiO 2 Nanoparticles and 182.6 mg of HAP powder were sequentially added to 100 mL of 1.5% SA solution. After it is mixed evenly, use a 30mL hypodermic syringe to pipette 15mL of the mixture into a 50mL beaker. Under magnetic stirring, 97.2 mg of GDL ...

Embodiment 3

[0065] A kind of Alg / TiO 2 -The concrete steps of the preparation method of CS-Col support material are:

[0066] with TiO 2 The nanoparticles acted as reinforcing agents, the HAP / GDL complex was the endogenous cross-linker for SA, and the EDC / NHS mixture was the covalent cross-linker for GT. And the molar ratio of HAP to GDL is 1:10, and the molar ratio of Ca in HAP to –COOH in SA is 0.36.

[0067] Preparation of immersion flushing solution: In 0.005mol / L calcium chloride solution, CS solution with a mass fraction of 0.8% and a collagen (Col) solution with a mass fraction of 1.5% were prepared for use.

[0068] 0.5g TiO 2 Nanoparticles and 365.2 mg of HAP powder were added into 100 mL of SA solution with a mass fraction of 2%, and mixed uniformly under the action of ultrasonic stirring. Then pipette 15mL of the mixture into a 50mL beaker. Under magnetic stirring, 194.4 mg of GDL was added. After high-speed stirring for 2 minutes, the mixture was quickly transferred to a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com