Preparation method and application of nano silver-bamboo shoot shell biochar composite material

A composite material and biochar technology, applied in separation methods, chemical instruments and methods, alkali metal compounds, etc., can solve the problems of poor selectivity, difficulty in using bamboo shoot shells, and small adsorption capacity, and achieve low cost and reduce environmental pollution. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

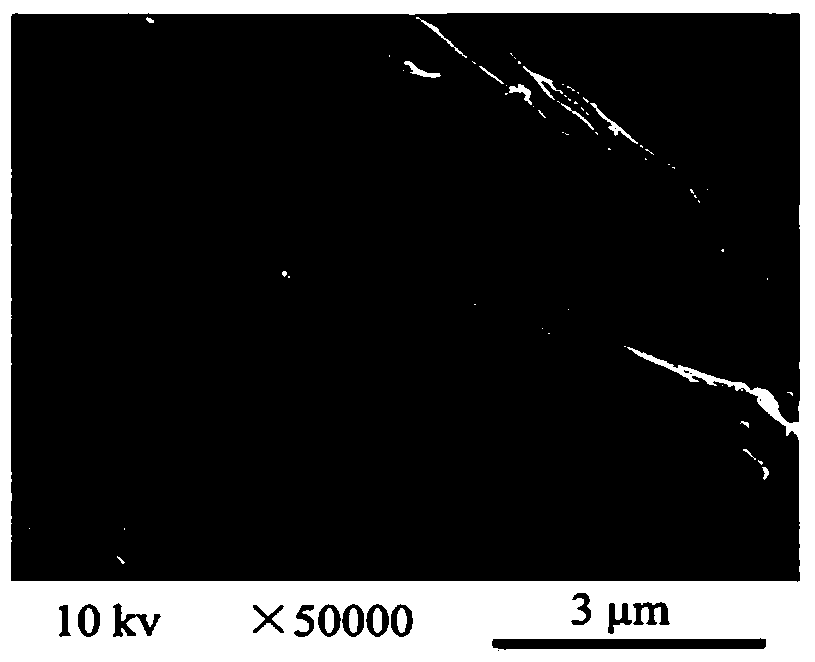

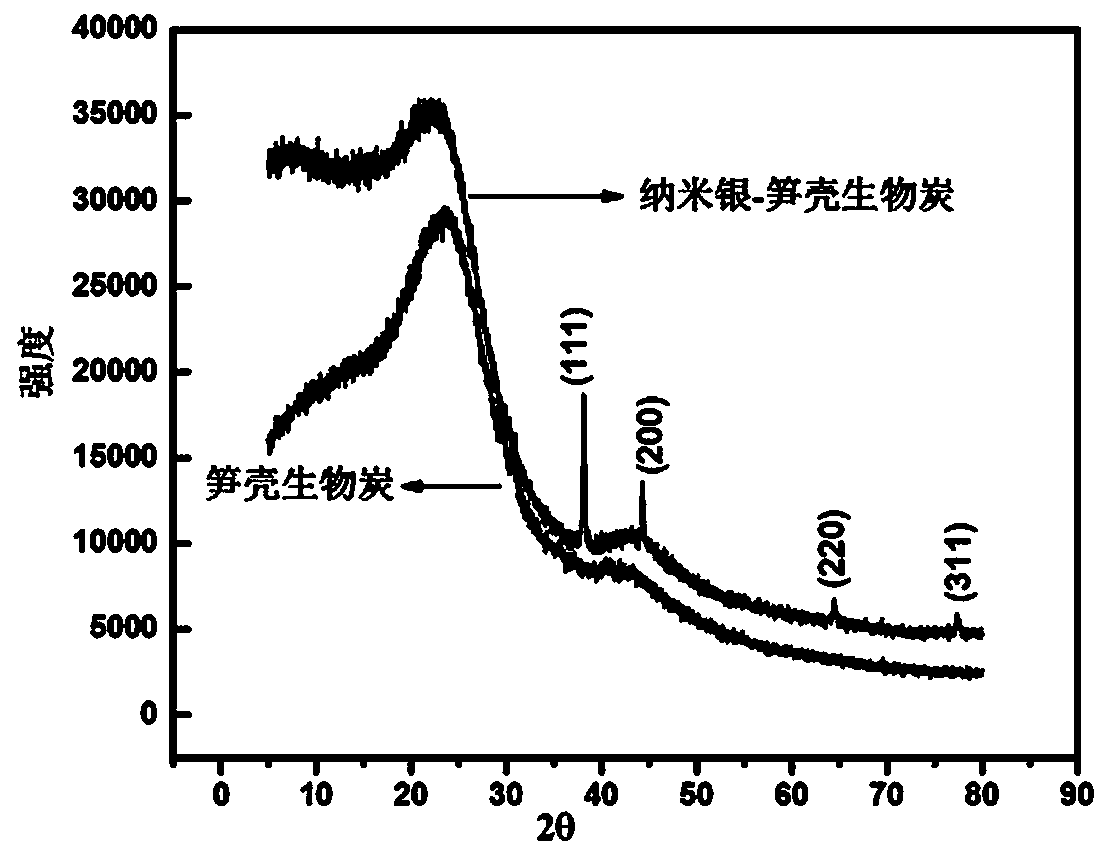

Image

Examples

Embodiment 1

[0029] A preparation method of nano silver-bamboo shoot shell biochar composite material, comprising the following steps:

[0030] (1) Granulation: wash the shells of bamboo shoots, dry them at 60°C, crush them, and pass through a 60-mesh sieve;

[0031] (2) Carbonization: Take an appropriate amount of sieved bamboo shoot shells, put them in a tube furnace, and put N 2 The flow rate was 100 mL / min, carbonized at 500 °C for 4 h, cooled to room temperature, taken out, washed until neutral, and dried to obtain bamboo shoot shell biochar;

[0032] (3) Silver loading: take 1 g of bamboo shoot shell biochar and 25 mL of silver nitrate-citric acid solution (the molar ratio of silver nitrate and citric acid is 1:1, the concentration of silver nitrate is 1 mmol / L, and the concentration of citric acid is 1 mmol / L. L) Mix, add 9 mL of 10 mmol / L ascorbic acid solution dropwise, place in a water bath at 25 °C, stir, soak for 6 h, filter, wash until neutral, and dry at 70 °C;

[0033] (4)...

Embodiment 2

[0035] A preparation method and application of nano silver-bamboo shoot shell biochar composite material, comprising the following steps:

[0036] (1) Granulation: wash the shells of bamboo shoots, dry them at 100°C, crush them, and pass through a 20-mesh sieve;

[0037] (2) Carbonization: Take an appropriate amount of sieved bamboo shoot shells, put them in a tube furnace, and put CO 2 The flow rate was 100 mL / min, carbonized at 200°C for 6 h, cooled to room temperature, taken out, washed until neutral, and dried to obtain bamboo shoot shell biochar;

[0038] (3) Silver loading: take 1g bamboo shoot shell biochar and 30mL silver nitrate-citric acid solution (the molar ratio of silver nitrate and citric acid is 1:1, the concentration of silver nitrate is 1 mmol / L, and the concentration of citric acid is 1 mmol / L ), then add 12 mL of 15 mmol / L ascorbic acid solution dropwise to the mixed solution, place in a water bath at 25 °C, stir, soak for 12 h, filter, wash until neutral,...

Embodiment 3

[0041] A preparation method and application of nano silver-bamboo shoot shell biochar composite material, comprising the following steps:

[0042] (1) Granulation: wash the bamboo shoot shells, dry them at 80°C, and then pulverize them to obtain the bamboo shoot shell powder and pass through a 100-mesh sieve;

[0043] (2) Carbonization: take an appropriate amount of sieved bamboo shoot shells, put them in a tube furnace, pass them into argon at a flow rate of 100 mL / min, carbonize at 600 °C for 2 h, take them out after cooling to room temperature, wash until neutral, and dry , to prepare bamboo shoot shell biochar;

[0044] (3) Silver loading: take 1 g of bamboo shoot shell biochar and 35 mL of silver nitrate-citric acid solution (the molar ratio of silver nitrate and citric acid is 1:1, the concentration of silver nitrate is 1 mmol / L, and the concentration of citric acid is 1 mmol / L. L) Mix, then add 15mL 20mmol / L ascorbic acid solution dropwise to the mixed solution, place ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com