Magnetron sputtering method for preparing all-inorganic perovskite solar cell

A solar cell and magnetron sputtering technology, applied in the field of magnetron sputtering, can solve the problems of large uncontrollable factors, expensive equipment, damage to perovskite films, etc., achieve high open circuit voltage and short circuit current density, and ensure surface finish. , reduce the effect of compounding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

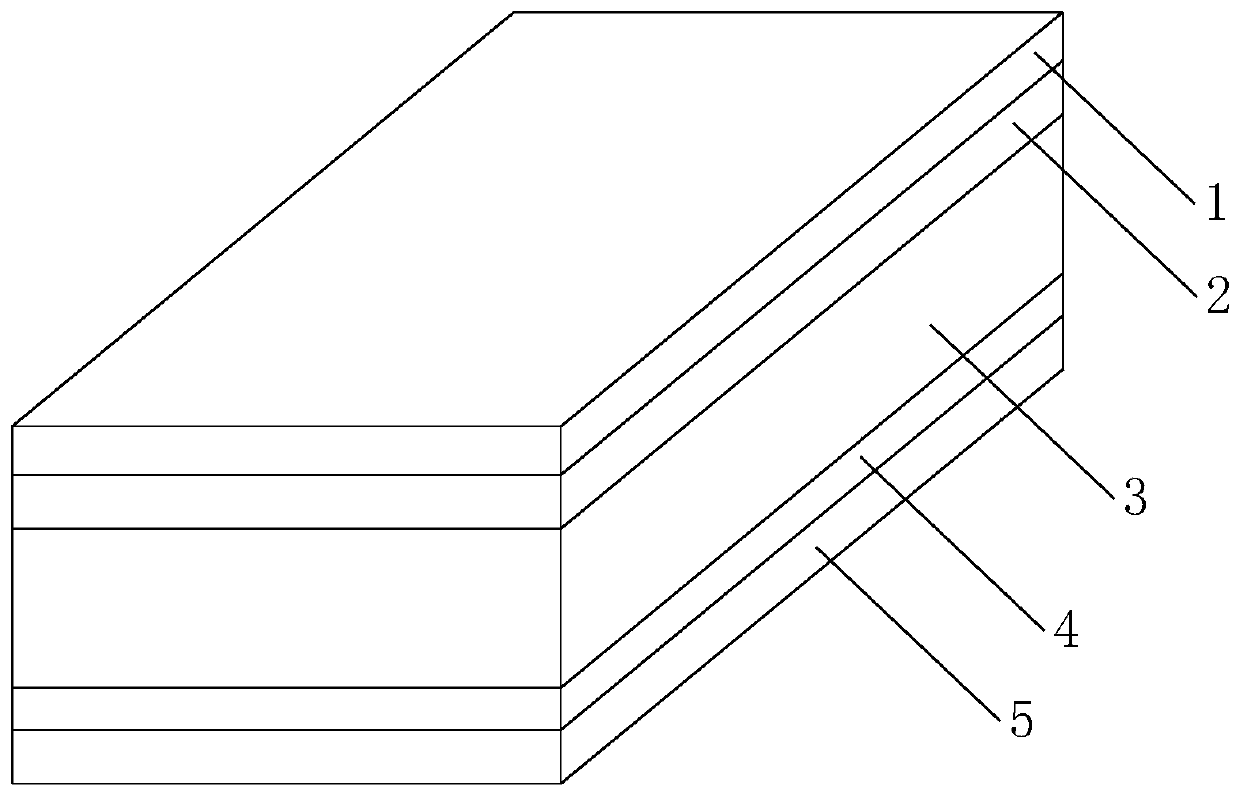

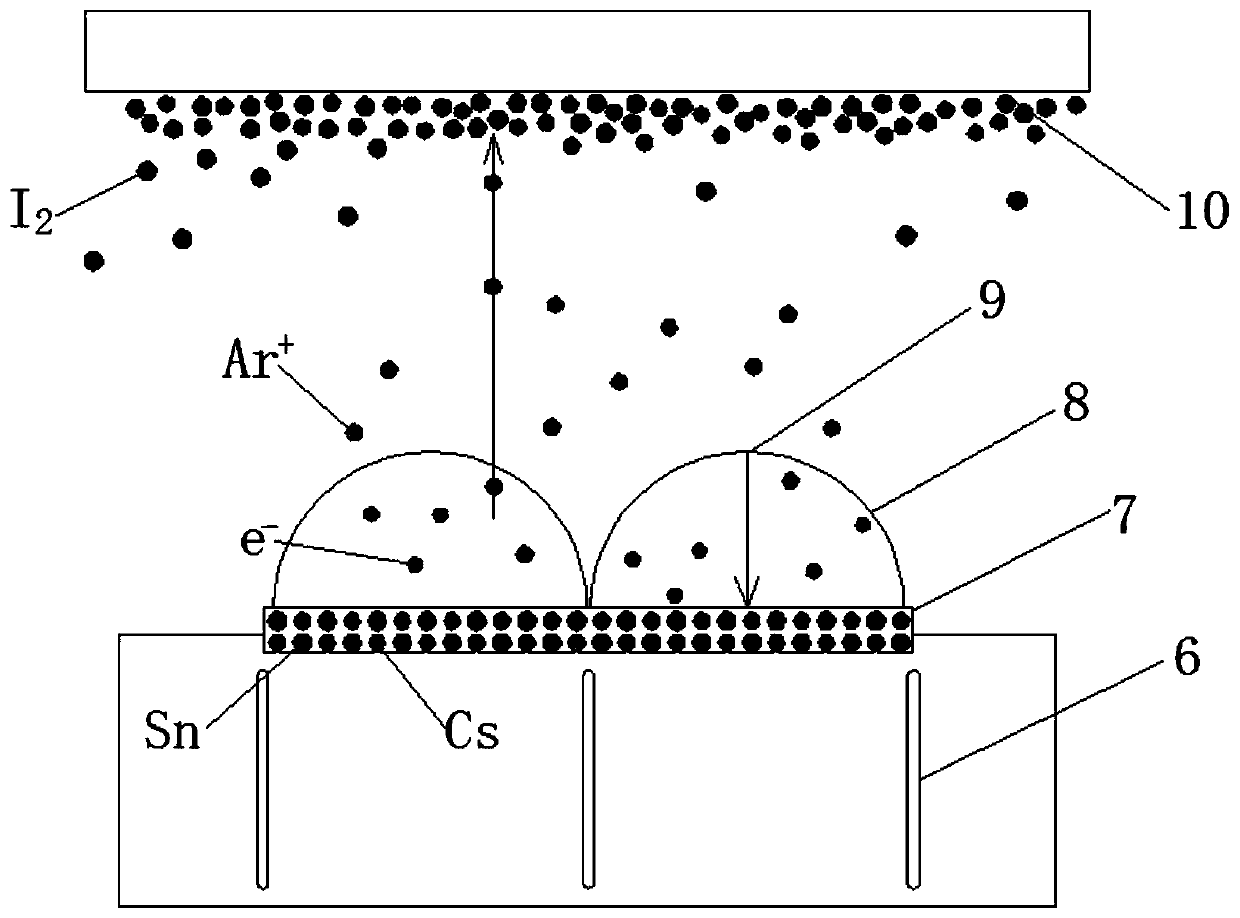

[0035] See figure 1 , figure 2 , a magnetron sputtering method for preparing an all-inorganic perovskite solar cell, the all-inorganic perovskite solar cell is sequentially composed of a substrate, a ZnO dense layer (electron transport layer), a perovskite CsSnI 3 Layer, CuI hole transport layer, metal gold electrode, the specific preparation method includes the following steps:

[0036] 1) Pre-treat the substrate; the substrate is FTO or ITO conductive glass, and the pre-treatment method is: first use a glass cleaning solution to clean the conductive glass; then immerse the conductive glass in acetone and ethanol solutions for ultrasonic cleaning; The conductive glass is rinsed with deionized water and ultrasonically cleaned; finally, the conductive glass is dried in an ozone cleaner.

[0037] 2) Magnetron sputtering ZnO dense layer on the substrate surface after pretreatment; the method of magnetron sputtering ZnO dense layer is: the substrate after pretreatment is placed...

Embodiment 2

[0042] See figure 1 , figure 2 , a magnetron sputtering method for preparing an all-inorganic perovskite solar cell, comprising the following steps:

[0043] 1) pre-treating the substrate;

[0044] First, use glass cleaning solution to clean the FTO conductive glass substrate; then immerse the substrate in acetone and ethanol solutions for 15 minutes of ultrasonic treatment; then rinse the substrate with deionized water and perform ultrasonic treatment for 15 minutes; finally, the substrate Dry in an ozone cleaner for 15 minutes.

[0045] 2) Magnetron sputtering ZnO dense layer on the substrate surface after pretreatment;

[0046] Among them, the method of magnetron sputtering ZnO dense layer is as follows: the pretreated substrate is placed in the radio frequency magnetron sputtering vacuum chamber, and the vacuum degree of the system is pumped to the background vacuum degree of 3×10 before coating. -3 Pa. Then filled with high-purity argon, working pressure 0.3Pa. The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com