All-solid-state polymer electrolyte with semi-interpenetrating network structure, and preparation method of electrolyte

An all-solid polymer and network structure technology, applied in the field of all-solid polymer electrolytes and their preparation, can solve the durability requirements and industrial applications of lithium-ion batteries without materials, solid polymer electrolytes have low room temperature ionic conductivity, electrolyte membranes Long-term use stability and other issues, to achieve the effect of improving the ionic conductivity at room temperature, improving the electrochemical window, and improving the lithium ion conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0042] In a second aspect, the present invention also provides a method for preparing the above-mentioned all-solid polymer electrolyte with a semi-interpenetrating network structure, which includes the following steps:

[0043] S1. Add the modified block copolymer, polyether acrylate oligomer monomer and an appropriate amount of solvent into the reactor together, under the protection of nitrogen or argon, and keep stirring for 1h-5h under light-proof conditions to form a uniform Precursor solution

[0044] S2. Add initiator, lithium salt and auxiliary agent to the precursor solution mentioned above, and stir to obtain a mixed solution; pour the mixed solution evenly into glass or a mold, seal it, and initiate the reaction under inert gas;

[0045] S3. After the initiation reaction is completed, vacuum drying is performed.

[0046] In the present invention, the molecular weight of the modified block copolymer is 10,000-1,000,000, such as 10,000, 50,000, 200,000, 500,000, 800,000, 1,00...

Embodiment 1

[0061] The preparation method of all solid polymer electrolyte with semi-interpenetrating network structure, the steps are as follows:

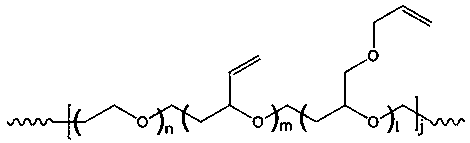

[0062] S1. Add 60 parts of modified block copolymer (molecular weight of 100000), 20 parts of polyethylene glycol diacrylate (molecular weight of 700) and 5ml of acetonitrile into the reactor, continue to vent nitrogen into the reactor, and Stirring continuously at a speed of 300r / min for 5h under dark conditions to form a uniform precursor solution; wherein the structural formula of the modified block copolymer is as follows:

[0063] ,

[0064] Where n: m: l = 93: 6:1, j = 23;

[0065] S2. Add 0.1 parts of azobisisobutyronitrile, 55 parts of lithium bistrifluoromethanesulfonimide and 20 parts of methoxypolyethylene glycol borate to the above precursor solution, and continue at a speed of 300r / min Stir for 5 hours to obtain a mixed solution; pour the mixed solution evenly into a polytetrafluoroethylene mold, seal it, and initiate the reaction unde...

Embodiment 2

[0068] The preparation method of all solid polymer electrolyte with semi-interpenetrating network structure, the steps are as follows:

[0069] S1. Add 95 parts of modified block copolymer (molecular weight of 10000), 50 parts of polyethylene glycol diacrylate (molecular weight of 400) and 6ml of tetrahydrofuran into the reactor, and continue to pass nitrogen into the reactor, and Stirring continuously for 5h at a speed of 100r / min under dark conditions to form a uniform precursor solution; wherein the structural formula of the modified block copolymer is as follows:

[0070]

[0071] Among them, n, m, l ∈ integer, and n ≥ 0, m ≥ 0, l ≥ 0, m and l are not at the same time 0, j ∈ integer, and j> 0;

[0072] S2. Add 1 part of benzophenone, 10 parts of lithium bisoxalate borate and 50 parts of vinyl ethylene carbonate to the above precursor solution, and continue to stir at 300r / min for 12h to obtain a mixed solution; pour the mixed solution evenly The initiation reaction is carried ou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com