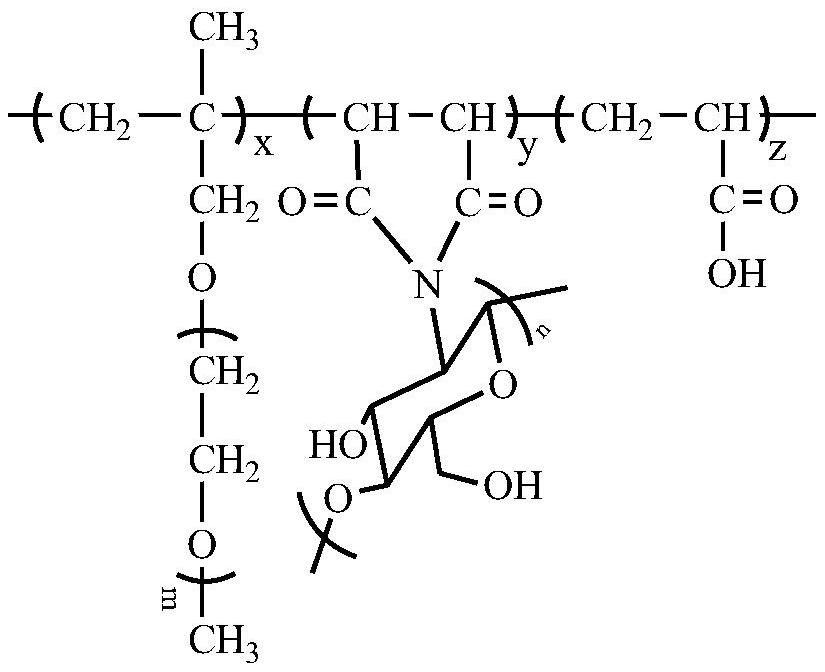

Chitosan oligosaccharide graft modified polycarboxylate water reducer and preparation method thereof

A technology of graft modification and water reducing agent, which is applied in the direction of amino sugar, etc., can solve the problems of poor water solubility, high molecular weight, low grafting rate, etc., and achieve improved viscosity increase and water retention, high polymerization activity, and small loss over time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

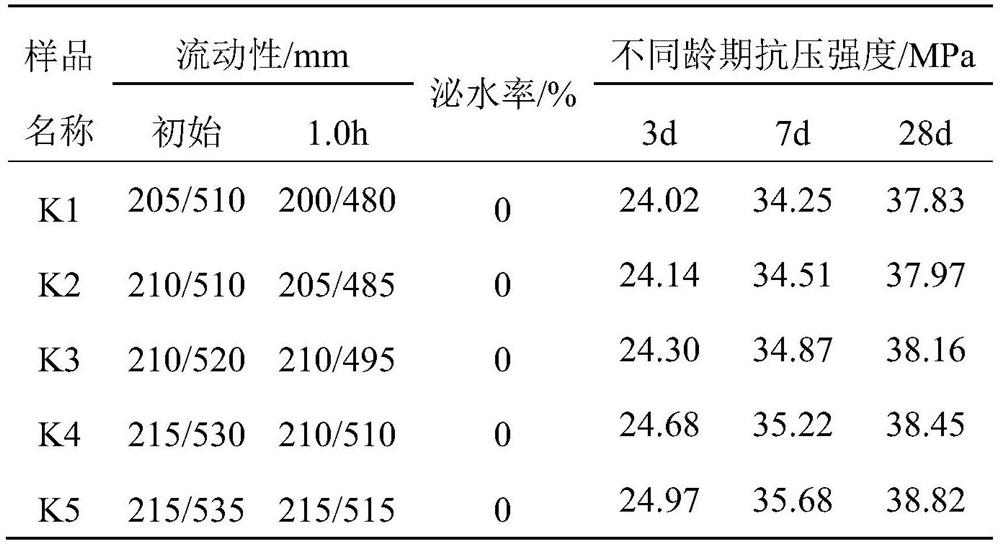

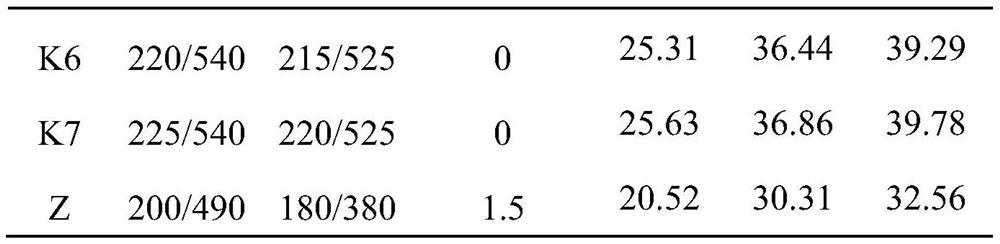

Examples

Embodiment 1

[0051] A kind of preparation method of chitosan oligosaccharide graft modified polycarboxylate water reducer, the steps are:

[0052] (1) Synthesis of Chitooligosaccharide Amidated Macromonomer:

[0053] Weigh chitooligosaccharide, maleic anhydride, and 4-dimethylaminopyridine successively in a molar ratio of 1:1.02:0.02;

[0054] At room temperature, dissolve chitosan and maleic anhydride with a molecular weight of 1000 and a degree of deacetylation of 90% in N,N-dimethylformamide, raise the temperature to 85°C, and add 4-dimethylaminopyridine as Catalyst, stirring reaction 3h. After the reaction is completed, the product is washed with acetone and water for 3 to 5 times respectively, placed in an oven at 45° C. and baked to constant weight to obtain a powdery chitosan oligosaccharide amidated macromonomer.

[0055] (2) Polymerization reaction:

[0056] Weigh methallyl polyoxyethylene ether, chitosan oligosaccharide amidated macromonomer, acrylic acid, 3-mercaptopropionic ...

Embodiment 2

[0061] A kind of preparation method of chitosan oligosaccharide graft modified polycarboxylate water reducer, the steps are:

[0062] (1) Synthesis of Chitooligosaccharide Amidated Macromonomer:

[0063] Weigh chitooligosaccharide, maleic anhydride, and 4-dimethylaminopyridine successively in a molar ratio of 1:1.05:0.025;

[0064] At room temperature, dissolve chitosan and maleic anhydride with a molecular weight of 1500 and a degree of deacetylation of 90% in N,N-dimethylformamide, raise the temperature to 88°C, and add 4-dimethylaminopyridine as Catalyst, stirring reaction 3h. After the reaction is completed, the product is washed with acetone and water for 3 to 5 times respectively, placed in an oven at 45° C. and baked to constant weight to obtain a powdery chitosan oligosaccharide amidated macromonomer.

[0065] (2) Polymerization reaction:

[0066] The molar ratio is 1.0:0.12:6.4:0.11:0.25:0.028 to weigh methallyl polyoxyethylene ether, chitooligosaccharide amidated ...

Embodiment 3

[0071] A kind of preparation method of chitosan oligosaccharide graft modified polycarboxylate water reducer, the steps are:

[0072] (1) Synthesis of Chitooligosaccharide Amidated Macromonomer:

[0073] Weigh chitooligosaccharide, maleic anhydride, and 4-dimethylaminopyridine successively in a molar ratio of 1:1.05:0.028;

[0074] At room temperature, dissolve chitosan and maleic anhydride with a molecular weight of 1500 and a degree of deacetylation of 92% in N,N-dimethylformamide, raise the temperature to 90°C, and add 4-dimethylaminopyridine as Catalyst, stirred and reacted for 3.5h. After the reaction is completed, the product is washed with acetone and water for 3 to 5 times respectively, placed in an oven at 45° C. and baked to constant weight to obtain a powdery chitosan oligosaccharide amidated macromonomer.

[0075] (2) Polymerization reaction:

[0076] The molar ratio is 1.0:0.14:6.7:0.14:0.3:0.03 and weighs methallyl polyoxyethylene ether, chitooligosaccharide a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com