Compound passion fruit and cumquat wine preparation method

A technology of passion fruit and passion fruit juice, which is applied in the field of food processing, can solve the problems of lack of deep-processed products and no production of whole fruit fermentation, etc., and achieve the effect of rich nutrition and flavor substances, unique fragrance and taste, and better health effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

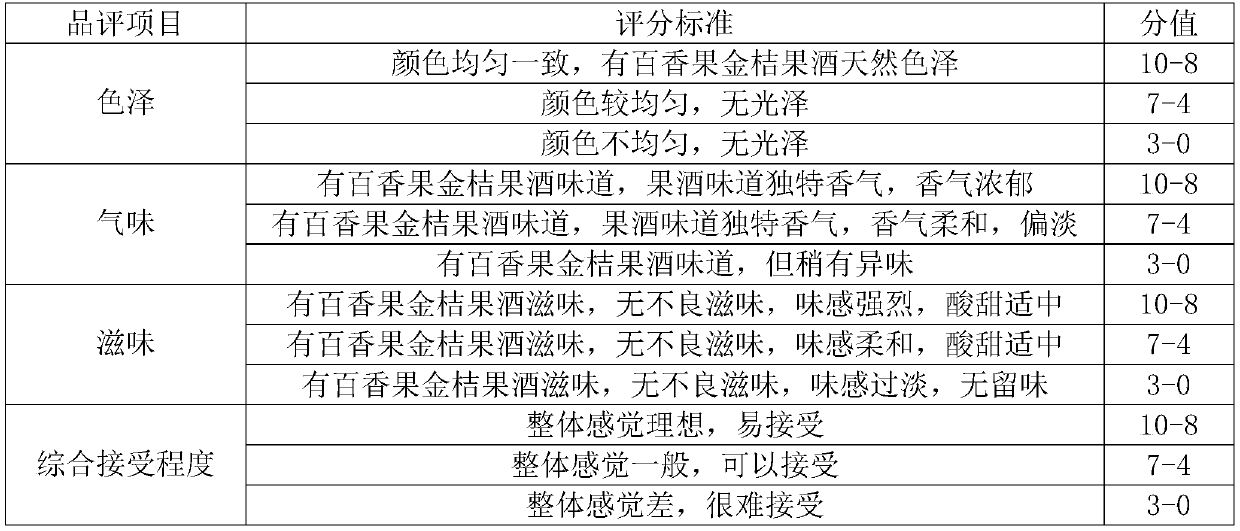

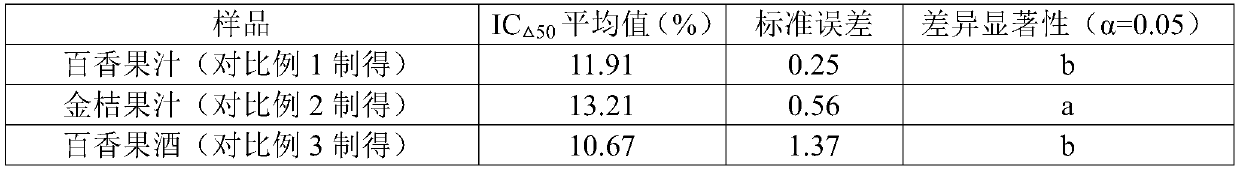

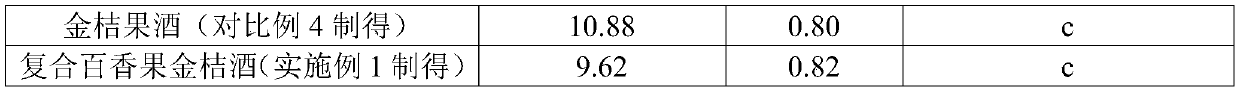

Examples

Embodiment 1

[0034] (1) prepare passion fruit, kumquat juice:

[0035] (a) Washing the whole passion fruit, beating and crushing the fruit and water according to the mass ratio of 1:3, enzymatic hydrolysis, boiling to inactivate the enzyme, cooling to obtain passion fruit juice;

[0036] (b) Washing the whole kumquat fruit, picking out the inner seeds, beating the fruit and water according to the mass ratio of 1:3, crushing, enzymolyzing, boiling to inactivate the enzyme, and cooling to obtain kumquat juice;

[0037] The enzymatic hydrolysis is as follows: adjust the pH value to 5.0 with sodium bicarbonate, add cellulase, pectinase, amylase, glucoamylase, protease, and the amount of cellulase is 30000U / kg (relative to the fruit raw material, the following same), the amount of pectinase added is 30000U / kg, the amount of amylase added is 5000U / kg, the amount of glucoamylase added is 5000U / kg, the amount of protease added is 15000U / kg, the enzymolysis temperature is 45℃, and the enzymolysis t...

Embodiment 2

[0042] (1) prepare passion fruit, kumquat juice:

[0043] (a) Wash the whole fruit of passion fruit, crush the fruit and water according to the mass ratio of 1:3, then enzymatically hydrolyze, boil to inactivate the enzyme, cool, add an adsorbent with an enzymatic hydrolyzate of 0.5% by weight for adsorption, and then filter, get passion fruit juice;

[0044] (b) Wash the whole kumquat fruit, pick out the inner seeds, beat the fruit and water according to the mass ratio of 1:3 and then enzymolyze it, boil it to kill the enzyme, cool it, and add 1.5% by weight of the enzymolyzed solution for adsorption agent adsorption, and then filtered to obtain kumquat juice.

[0045] Wherein the enzymolysis method is with embodiment 1.

[0046] (2) Alcoholic fermentation: After mixing the passion fruit juice and kumquat fruit juice obtained in step (1) in a ratio of 2:1, add 3% (mass volume ratio) of yeast seed liquid to inoculate and ferment, adjust the initial pH 4.0, and the temperatur...

Embodiment 3

[0050] (1) prepare passion fruit, kumquat fruit juice: step is with embodiment 1.

[0051] (2) Alcoholic fermentation: After mixing the passion fruit juice and kumquat fruit juice obtained in step (1) in a ratio of 2:1, add 0.2% (mass volume ratio) of Saccharomyces cerevisiae powder for inoculation and fermentation, adjust the initial pH4.5, temperature 28°C, fermented for 7 days, the fermentation alcohol content reached 11.3%.

[0052] (3) Filtration: after the compound passion fruit kumquat wine mash after step (2) fermentation finishes is filtered, the compound passion fruit kumquat wine of clarification is obtained;

[0053] (4) Product testing: the results of sensory testing are shown in Table 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com