Polycarbonate composition and preparation method thereof

A technology of polycarbonate and composition, which is applied in the field of scratch-resistant, high-gloss, high-toughness polycarbonate composition and its preparation, which can solve the limitation of PC/PMMA alloy material application and insufficient impact toughness of PC/PMMA alloy , Difficulty in uniform mixing, etc., to achieve the effect of improving surface scratch resistance, improving compatibility and toughness, and improving compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

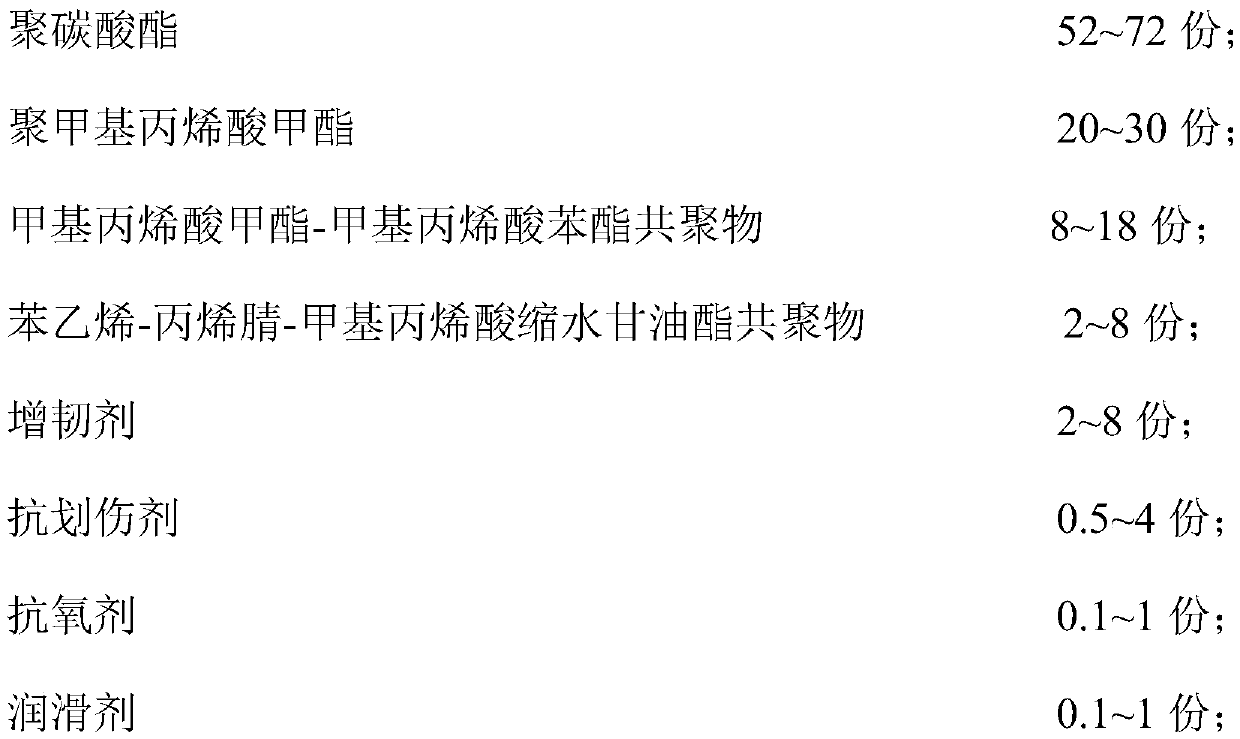

[0061] This embodiment provides a kind of high gloss, scratch resistance, high tenacity polycarbonate composition, and its raw material composition and parts by weight are:

[0062]

[0063]

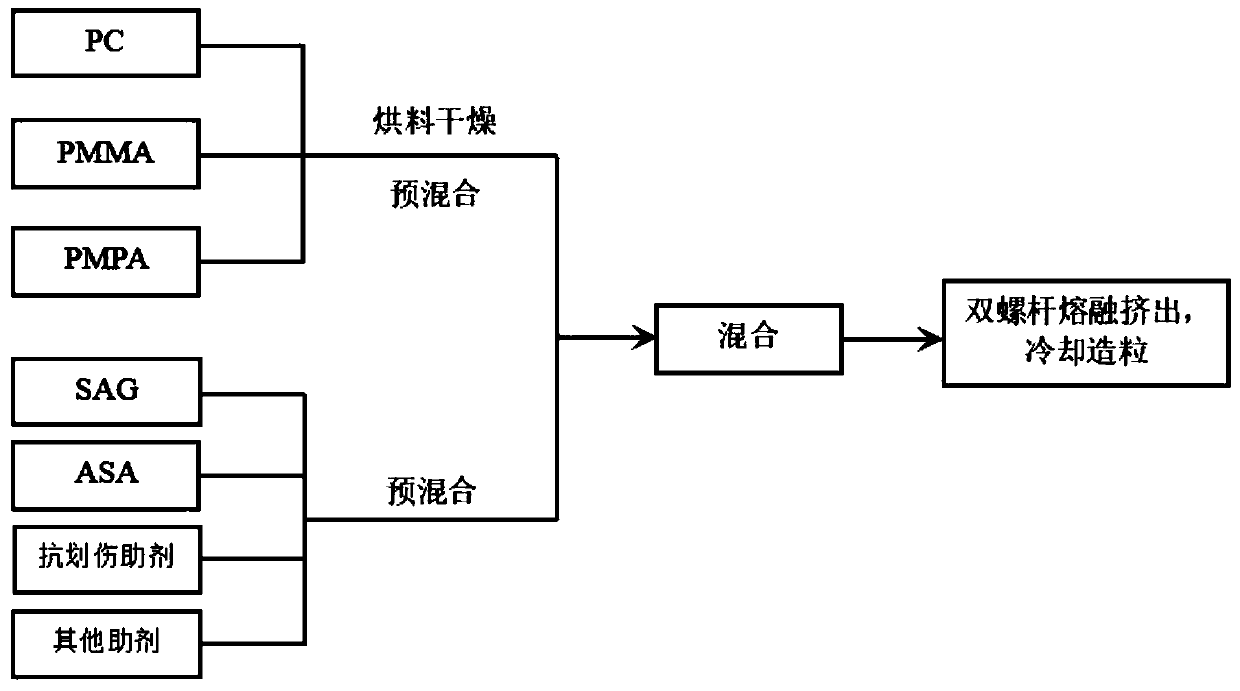

[0064] The preparation method of the high-gloss, scratch-resistant, high-toughness polycarbonate composition of the present embodiment may further comprise the steps:

[0065] (1) Dry PC resin at 120°C for 4 hours, PMMA resin and PMPA resin at 80°C for 4 hours, after cooling, accurately weigh the materials according to the stated ratio, and then add them to a high-speed mixer for pre-mixing ( The rotation speed is 50rpm);

[0066] (2) Add compatibilizer SAG-002, toughening agent ASA-600A, anti-scratch agent SI-S50, anti-scratch agent KJ-B01, antioxidant 1076, antioxidant 168 and lubricant PETS into another After carrying out pre-mixing (rotating speed is 50rpm) in a high-speed mixer, gained mixture is joined in the high-speed mixer in step (1) and mixes (rotating speed is 50rpm); ...

Embodiment 2

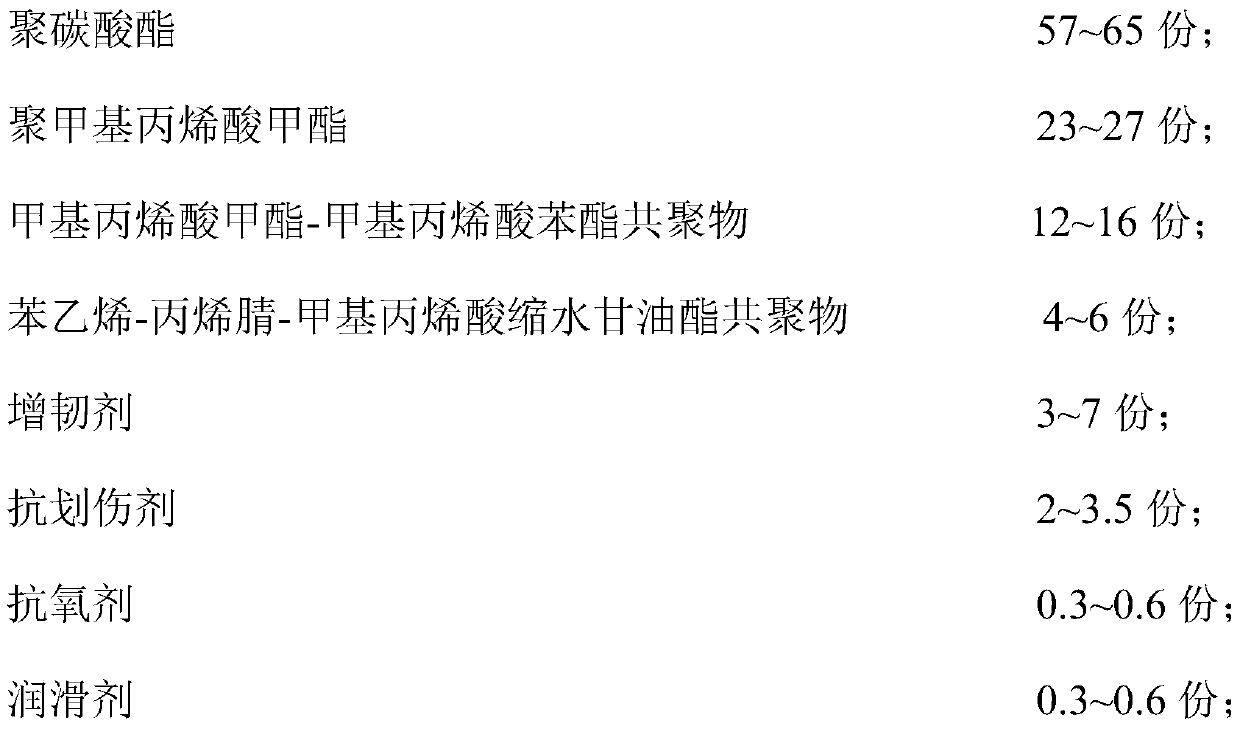

[0069] This embodiment provides a kind of high gloss, scratch resistance, high tenacity polycarbonate composition, and its raw material composition and parts by weight are:

[0070]

[0071]

[0072] The preparation method of the high-gloss, scratch-resistant, high-toughness polycarbonate composition of the present embodiment may further comprise the steps:

[0073] (1) Bake PC resin at 120°C for 4h, PMMA and PMPA resin at 80°C for 4h, after cooling, accurately weigh the materials according to the stated ratio, and then add them to a high-speed mixer for pre-mixing (rotating speed 50rpm);

[0074] (2) Add compatibilizer SAG-002, toughening agent ASA-600A, anti-scratch agent SI-S50, anti-scratch agent KJ-B01, antioxidant 1076, antioxidant 168 and lubricant PETS into another After carrying out pre-mixing (rotating speed is 50rpm) in a high-speed mixer, gained mixture is joined in the high-speed mixer in step (1) and mixes (rotating speed is 50rpm);

[0075] (3) Transfer ...

Embodiment 3

[0077] This embodiment provides a kind of high gloss, scratch resistance, high tenacity polycarbonate composition, and its raw material composition and parts by weight are:

[0078]

[0079] The preparation method of the high-gloss, scratch-resistant, high-toughness polycarbonate composition of the present embodiment may further comprise the steps:

[0080] (1) Bake PC resin at 120°C for 4h, PMMA and PMPA resin at 80°C for 4h, after cooling, accurately weigh the materials according to the stated ratio, and then add them to a high-speed mixer for pre-mixing (rotating speed 50rpm);

[0081] (2) Add compatibilizer SAG-002, toughening agent ASA-600A, anti-scratch agent SI-S50, anti-scratch agent KJ-B01, antioxidant 1076, antioxidant 168 and lubricant PETS into another After carrying out pre-mixing (rotating speed is 50rpm) in a high-speed mixer, gained mixture is joined in the high-speed mixer in step (1) and mixes (rotating speed is 50rpm);

[0082] (3) Transfer the mixture ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com