Preparation method of flower-like MoO2 (Molybdenum dioxide) nano material

A nano-material and flower-shaped technology, which is applied in the field of preparation of flower-shaped MoO2 nano-materials, can solve the problems of low production efficiency, inapplicability, and high consumption of isopropanol, and achieve low production costs, high product yields, and process pollution. small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0036] The invention relates to a flower-shaped MoO 2 A method for preparing nanomaterials, comprising:

[0037] S1: Add citric acid to the suspension of molybdenum acetylacetonate, and completely dissolve the molybdenum acetylacetonate by at least one mode of ultrasonic dispersion, stirring or shaking to obtain a reaction system;

[0038] S2: the reaction system is placed in a high-pressure reactor for hydrothermal reaction to obtain a black-gray precipitate;

[0039] S3: Collect the precipitate.

[0040]Preferably, in S1, the suspension of molybdenum acetylacetonate is obtained by dispersing molybdenum acetylacetonate in deionized water, and the concentration of the suspension of molybdenum acetylacetonate is 0.1-0.5mmol / L; for example, the concentration is 0.10mmol / L , 0.25mmol / L, 0.5mmol / L.

[0041] As a preferred embodiment of the present invention, in S1, the amount of citric acid added is such that the mass ratio of molybdenum acetylacetonate is 5-15:1. Preferably 7...

Embodiment 1

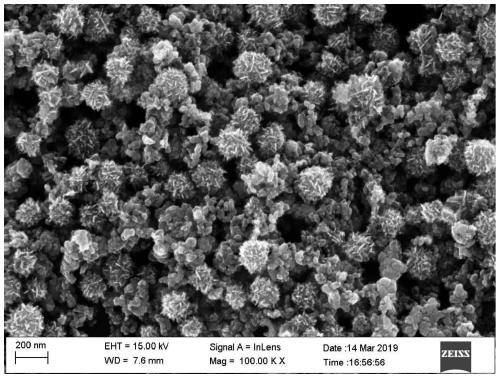

[0048] combine figure 1 As shown, this embodiment provides a flower-like MoO 2 A method for preparing a nanomaterial, comprising the steps of:

[0049] (1) Weigh molybdenum acetylacetonate particles and dissolve them in ultrapure water to prepare 15 mL of molybdenum acetylacetonate suspension with a concentration of 0.1 mmol / L, which is recorded as A.

[0050] (2) Add 0.5 g of citric acid particles to A, ultrasonically disperse, and magnetically stir for 2 hours until the molybdenum acetylacetonate particles are completely dissolved.

[0051] (3) Put the above solution into an autoclave and heat it at 160° C. for 10 hours to obtain a black-gray precipitate.

[0052] (4) Centrifuge the product mixture at 4000 rpm for 10 min in a centrifuge, remove the supernatant, and collect the precipitate.

[0053] (5) Use deionized water and ethanol to disperse and wash the precipitate twice respectively, centrifuge the product, and finally put it in a drying oven at 60°C for 3 hours to ...

Embodiment 2

[0060] This embodiment provides a flower-like MoO 2 The preparation method of the nanomaterial is the same as that of Example 1, except that the hydrothermal reaction temperature is increased by 180° C., and the reaction is carried out for 8 hours. The experimental results are almost the same as in Example 1, and the flower-shaped MoO with a diameter of 100-200nm is obtained. 2 nanoparticles.

[0061] This shows that the effect of the hydrothermal reaction time on the product is not obvious within 8-12 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com