A kind of high-hardness high-boron wear-resistant cast steel and its preparation method

A high-hardness, high-boron technology, applied in the field of wear-resistant cast steel, can solve the problems of increasing manufacturing costs, uneconomical, and adding technological processes, and achieve the effects of improved wear resistance, improved brittleness, and simple technological processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

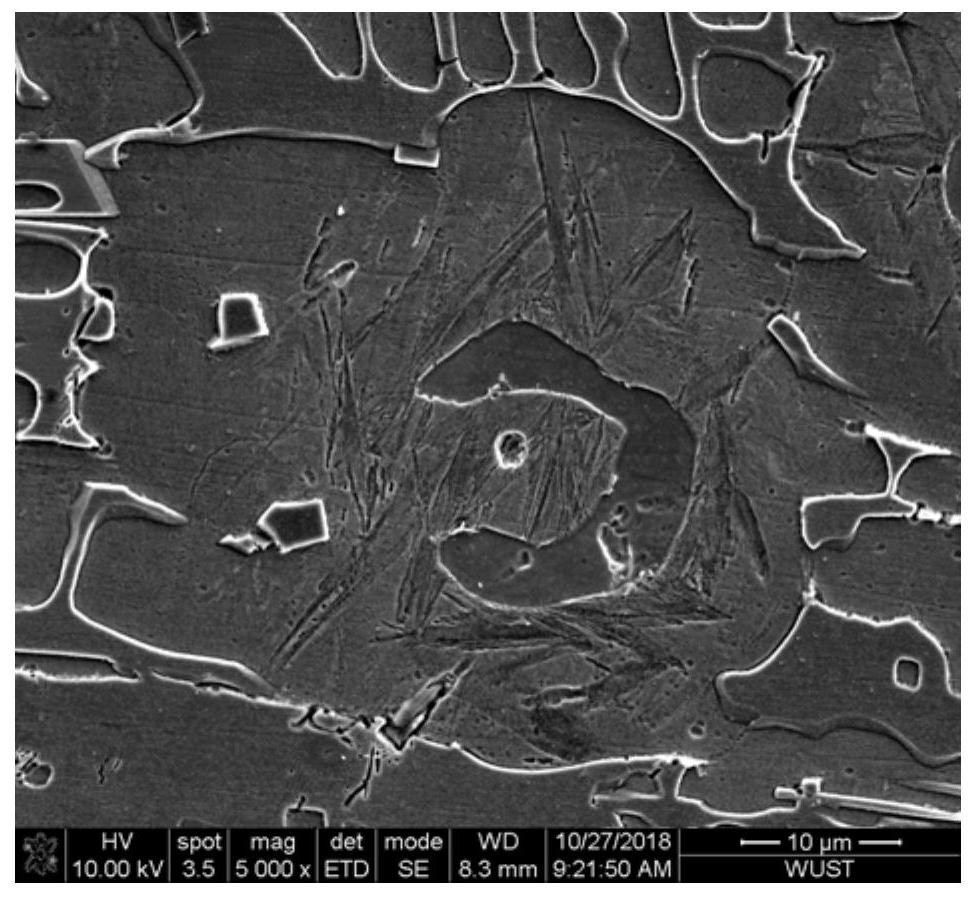

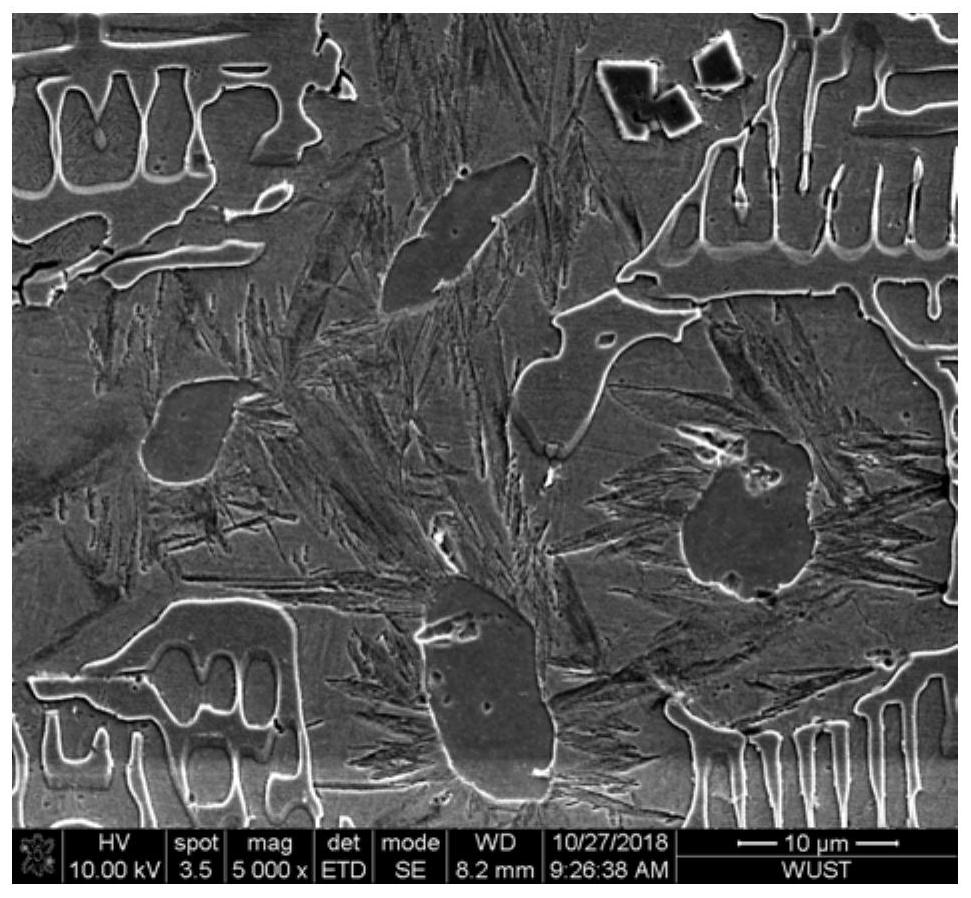

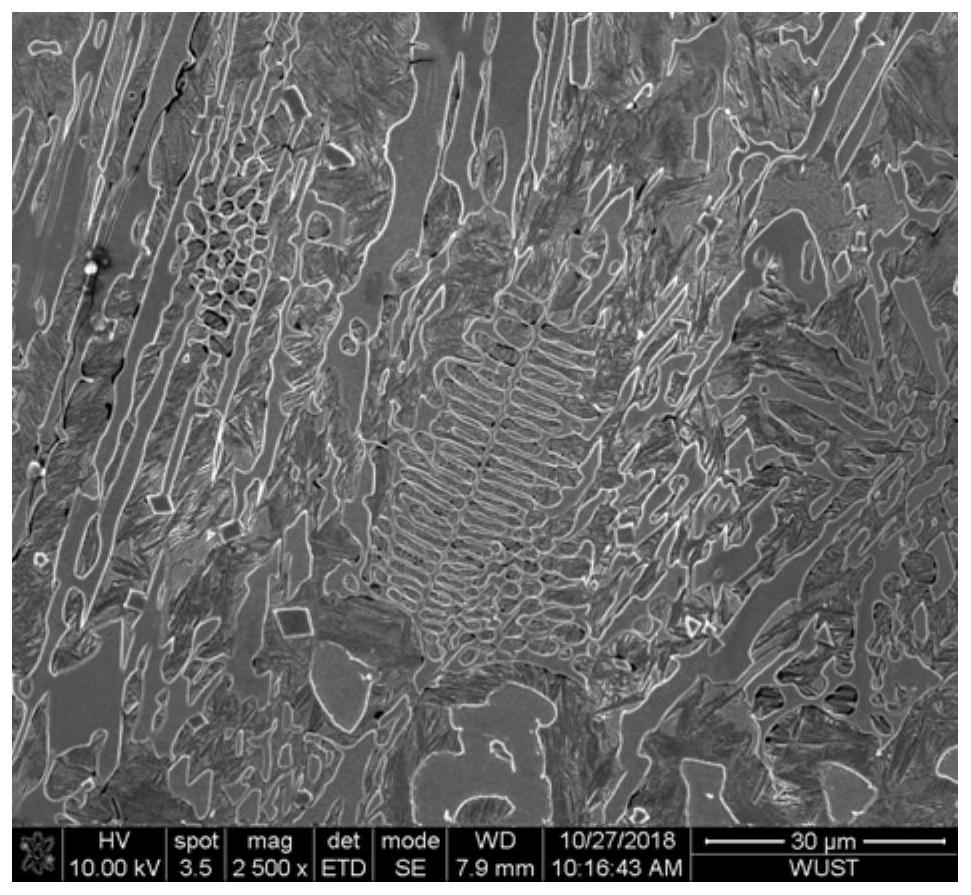

Image

Examples

specific Embodiment approach

[0023] The particle size of the carburant is 1-5mm;

[0024] The particle size of the ferrotitanium alloy, rare earth magnesium silicon alloy and rare earth ferrosilicon alloy is 2-6 mm;

[0025] The casting temperature of the casting is 20-100° C. on the liquidus line of the alloy.

[0026] No more details will be given in the embodiments.

Embodiment 1

[0028] A high-hardness, high-boron wear-resistant cast steel and a preparation method thereof. The preparation method described in this embodiment is:

[0029] The chemical composition of the high-hardness and high-boron wear-resistant cast steel is: B is 1.5-2.0wt%; C is 0.2-0.4wt%; Al is 0.5-0.6wt%; Si is 0.7-0.8wt%; Mn is 4.0 ~5.0wt%; Ti is 0.3~0.4wt%; Ce is 0.4~0.5wt%; Mg is 0.4~0.5wt%; S﹤0.03wt%; P﹤0.04wt%; the balance is Fe and other unavoidable Impurities.

[0030] The preparation method of the high-hardness and high-boron wear-resistant cast steel is as follows: first, scrap steel, pig iron, ferroboron, ferrosilicon, ferromanganese, ferrotitanium, rare earth magnesium silicon alloy, rare earth ferrosilicon alloy and recarburizer according to the high hardness The chemical composition of high-boron wear-resistant cast steel is batched; then the ferrotitanium, rare earth magnesium-silicon alloy and rare earth ferrosilicon alloy are preset at the bottom of the ladle, an...

Embodiment 2

[0035] A high-hardness, high-boron wear-resistant cast steel and a preparation method thereof. The preparation method described in this embodiment is:

[0036] The chemical composition of the high-hardness and high-boron wear-resistant cast steel is: B is 2.0-2.5wt%; C is 0.4-0.6wt%; Al is 0.6-0.7wt%; Si is 0.8-0.9wt%; Mn is 5.0 ~6.0wt%; Ti is 0.35~0.45wt%; Ce is 0.45~0.55wt%; Mg is 0.45~0.55wt%; S﹤0.03wt%; P﹤0.04wt%; the balance is Fe and other unavoidable Impurities.

[0037] The preparation method of the high-hardness and high-boron wear-resistant cast steel is as follows: first, scrap steel, pig iron, ferroboron, ferrosilicon, ferromanganese, ferrotitanium, rare earth magnesium silicon alloy, rare earth ferrosilicon alloy and recarburizer according to the high hardness The chemical composition of high-boron wear-resistant cast steel is batched; then the ferrotitanium, rare earth magnesium-silicon alloy and rare earth ferrosilicon alloy are preset at the bottom of the lad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| microhardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com