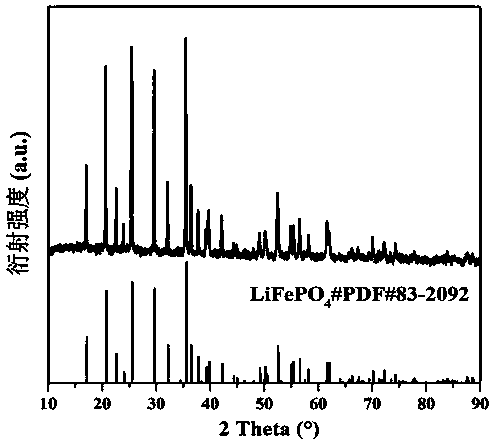

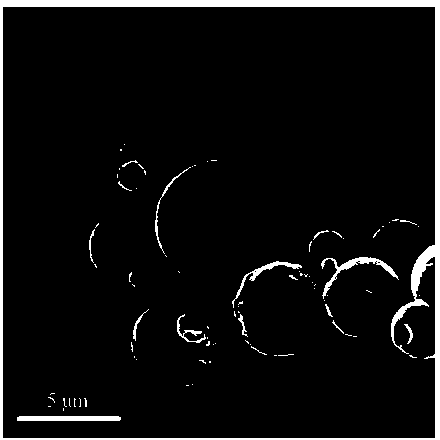

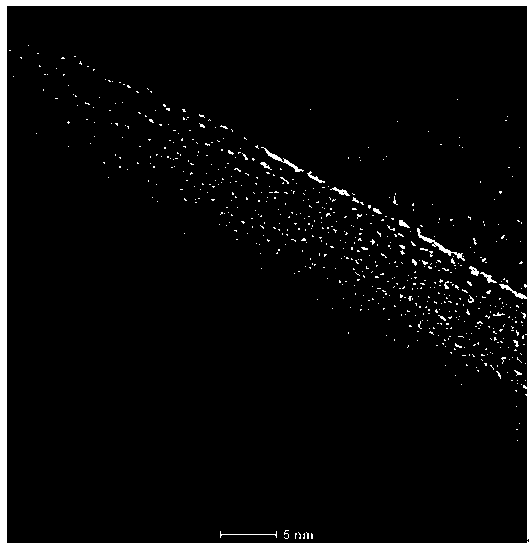

Method for regenerating lithium iron phosphate by leaching, spray drying and solid phase method

A technology of lithium iron phosphate and solid-phase method, which is applied in recycling technology, recycling by waste collectors, electrical components, etc., can solve problems such as poor chemical properties and complicated process of regenerating lithium iron phosphate, and achieve good dispersion and good circulation Stability and reversibility, good effect of crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Embodiment 1: A method for regenerating lithium iron phosphate by leaching-spray drying-solid phase method, the specific steps are as follows:

[0031] (1) Put the waste lithium iron phosphate battery in the salt solution (Na 2 SO 4 solution), where the salt solution (Na 2 SO 4 solution) with a mass concentration of 3%; then manually disassemble and separate the positive electrode sheet;

[0032] (2) Heat and calcinate the positive electrode sheet in step (1) to obtain aluminum foil and waste lithium iron phosphate positive electrode; the temperature of calcination is 500°C, and the time is 2h;

[0033] (3) Washing, drying, and pulverizing the waste lithium iron phosphate in step (2) to obtain waste lithium iron phosphate cathode powder;

[0034] (4) Add the waste lithium iron phosphate positive electrode powder in step (3) into the acid solution (hydrochloric acid) for leaching to obtain a leaching solution; the concentration of the acid solution (hydrochloric acid...

Embodiment 2

[0044] Example 2: The method of regenerating lithium iron phosphate by leaching-spray drying-solid-phase method in this example is basically the same as the method of regenerating lithium iron phosphate by leaching-spray drying-solid-phase method in Example 1, except that: The salt solution in (1) is sodium nitrate, and the mass concentration of the salt solution (sodium nitrate) is 5%; the temperature of calcination in step (2) is 400°C, and the time is 5h; the acid solution (hydrochloric acid) in step (4) The concentration is 0.5mol / L; In step (5), the lithium source is lithium hydroxide, the iron source is ferric chloride, and the phosphorus source is diammonium hydrogen phosphate;

[0045] The lithium iron phosphate regenerated in this embodiment is assembled into a 2025 button battery according to the conventional method, and its electrochemical performance is tested: the first charge and discharge curve of the regenerated lithium iron phosphate in this embodiment shows th...

Embodiment 3

[0048] Example 3: The method of regenerating lithium iron phosphate by leaching-spray drying-solid-phase method in this example is basically the same as the method of regenerating lithium iron phosphate by leaching-spray drying-solid-phase method in Example 1, except that: The salt solution in (1) is potassium nitrate, and the mass concentration of the salt solution (potassium nitrate) is 1%; the temperature of calcination in step (2) is 600°C, and the time is 0.5h; the acid solution (sulfuric acid) in step (4) ) concentration is 1.0 mol / L; in step (5), the lithium source and the phosphorus source are lithium phosphate, and the iron source is iron powder;

[0049] The lithium iron phosphate regenerated in this embodiment is assembled into a 2025 button battery according to the conventional method, and its electrochemical performance is tested: the first charge and discharge curve of the regenerated lithium iron phosphate in this embodiment shows that the regenerated lithium iro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com