Preparation method of green AIN:Tb fluorescent powder material

A technology of fluorescent powder and bulk materials, applied in the direction of luminescent materials, chemical instruments and methods, etc., can solve the problems of high reaction temperature, low powder bulk density, complex equipment, etc., and achieve simple preparation process, low nitriding temperature, and preparation low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

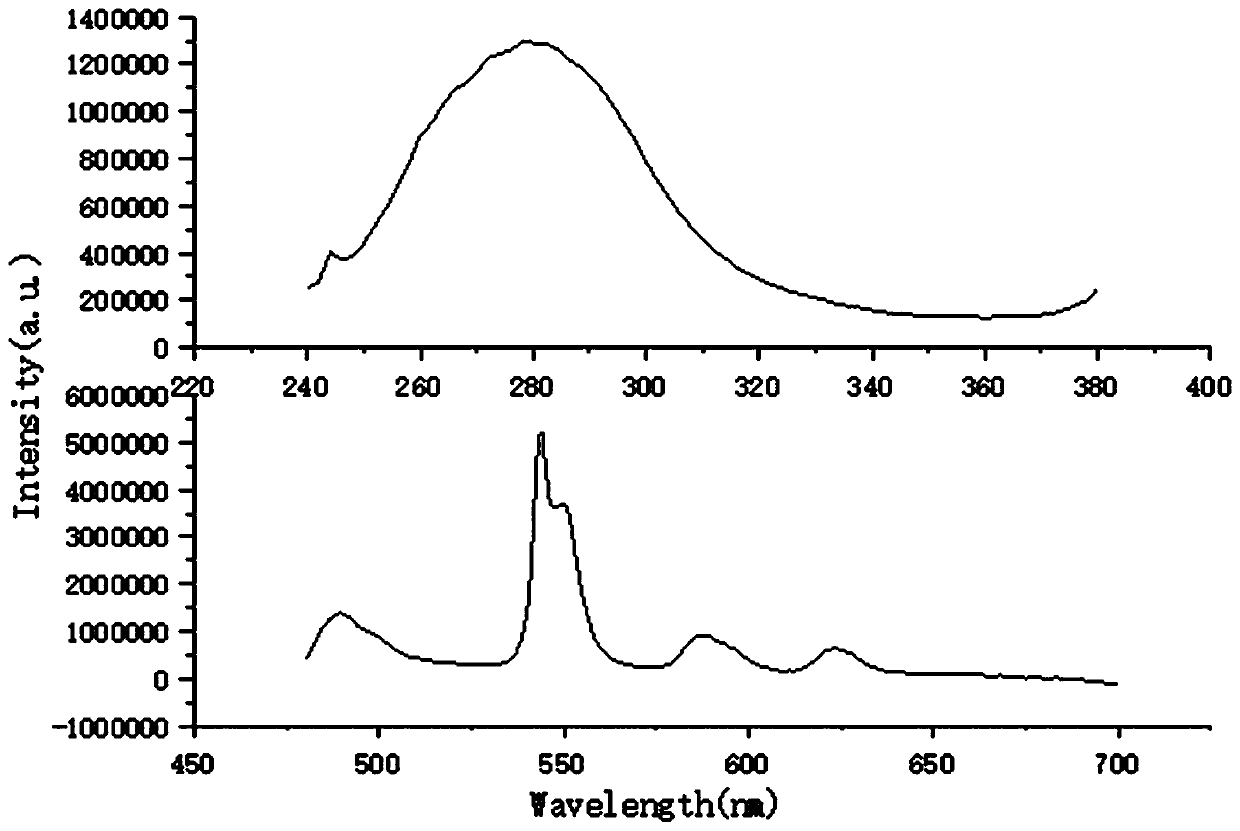

Image

Examples

Embodiment Construction

[0029] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0030] A kind of preparation method of green Al:Tb fluorescent powder body material, comprises the following steps:

[0031] S1), the preparation of reaction precursor powder, adding aluminum powder, magnesium powder, ammonium chloride, and terbium powder with a mass ratio of 9:1:3:0.06 into a ceramic mortar and grinding to make the four powders fully mixed, and then transferred to oxidation In the aluminum ceramic ark, the reaction precursor powder is obtained;

[0032] S2), nitriding, the alumina ceramic ark that 4 kinds of powders are housed in step S1) is put into the tube-type resistance furnace, at first pass into nitrogen to get rid of water vapor in the tube-type resistance furnace, then the reaction of the tube-type furnace Set the temperature to 900°C, and then run the tubular resistance furnace. When the temperature rises to 500°C-600°...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com