A kind of high-purity aluminum nitride powder and its preparation method

A technology of aluminum nitride and powder, which is applied in the field of high-purity aluminum nitride powder and its preparation, can solve the problems of complex process and low purity of aluminum nitride powder, and achieve simple process, high single-shot output and uniform particle size Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

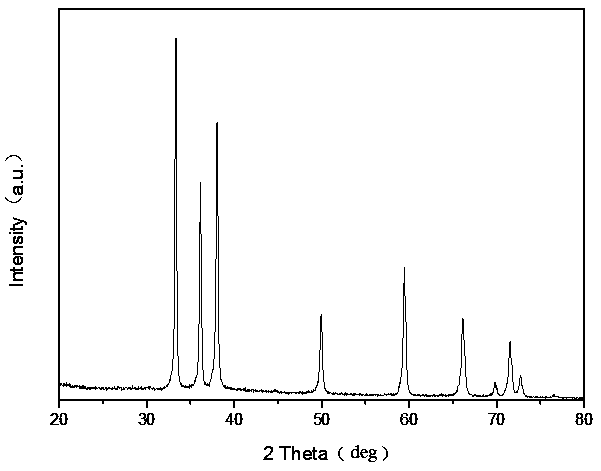

Image

Examples

Embodiment 1

[0024] Weigh 50g of metal Al powder with a purity of 99.99wt%, a spherical particle shape, and a particle size of 20μm in a glove box, and then weigh 5g of a reaction with a purity of 99.99wt%, a spherical particle shape, and a particle size of 2μm Additive AlN powder (additive A), mixed thoroughly for 20 minutes and then charged into a molybdenum crucible. Put the mixed material into the sintering furnace, evacuate it to 20KPa, feed in a nitrogen-hydrogen mixture with a volume ratio of 1:1, control the flow rate at 1.5L / min, and then raise the temperature at a rate of 5°C / min to 600°C, holding time 4h. Afterwards, the temperature was lowered to 300°C at a rate of 5°C / min, and naturally cooled to room temperature to obtain a primary sintered product, which was then ball milled in a glove box to about 3 μm for use.

[0025] Add reaction flux B (NH 4 HCO 3 and AlCl 3 The mixture, the mass ratio is 1:2) 1.67g, after fully mixing for 20 minutes, put it into the vacuum box furn...

Embodiment 11-17

[0033] With reference to the preparation method of Example 1, change the particle size of the primary sintered product to be used, NH in flux B 4 HCO 3 and AlCl 3 The ratio of other process conditions is the same as in Example 1. The N content and particle morphology of the aluminum nitride powder obtained are tested, and the results are shown in Table 2.

[0034] Table 2

[0035]

[0036] It can be seen from Table 2 that the particle size of the primary sintered product directly affects the particle size of the product, and the product particle size can be adjusted by changing the particle size of the primary sintered product as required. NH in flux B 4 HCO 3 with AlCl 3 The mass ratio of the product has a great influence on the particle size and uniformity of the product, and its optimal ratio is 1:2.

Embodiment 18-34

[0038] With reference to the preparation method of Example 1, the primary sintering conditions and secondary sintering conditions were changed, and other process conditions were the same as in Example 1. The N content and particle morphology of the prepared aluminum nitride powder were tested, and the results are shown in the table 3.

[0039] table 3

[0040]

[0041] It can be seen from Table 3 that by changing the temperature and holding time of the primary sintering and secondary sintering, as the sintering temperature increases, the nitriding rate first increases and then decreases, and the particle uniformity first becomes better and then gradually deteriorates , the particles agglomerate and the particle size becomes larger; with the extension of the holding time, the nitriding rate is slightly improved and the particle size becomes larger; when the primary sintering temperature is 600°C, the holding time is 4h, and the secondary sintering temperature is 900°C , whe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com